Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small torsion springs, often overlooked due to their size, are mighty components that play a crucial role in a wide range of applications. They are marvels of engineering, meticulously crafted

Small torsion springs, often overlooked due to their size, are mighty components that play a crucial role in a wide range of applications. They are marvels of engineering, meticulously crafted to provide a precise twisting force, ensuring smooth operation and reliable performance in various devices. From delicate watches to sophisticated medical equipment, small torsion springs are the silent heroes, working diligently behind the scenes to make our lives easier and more efficient.

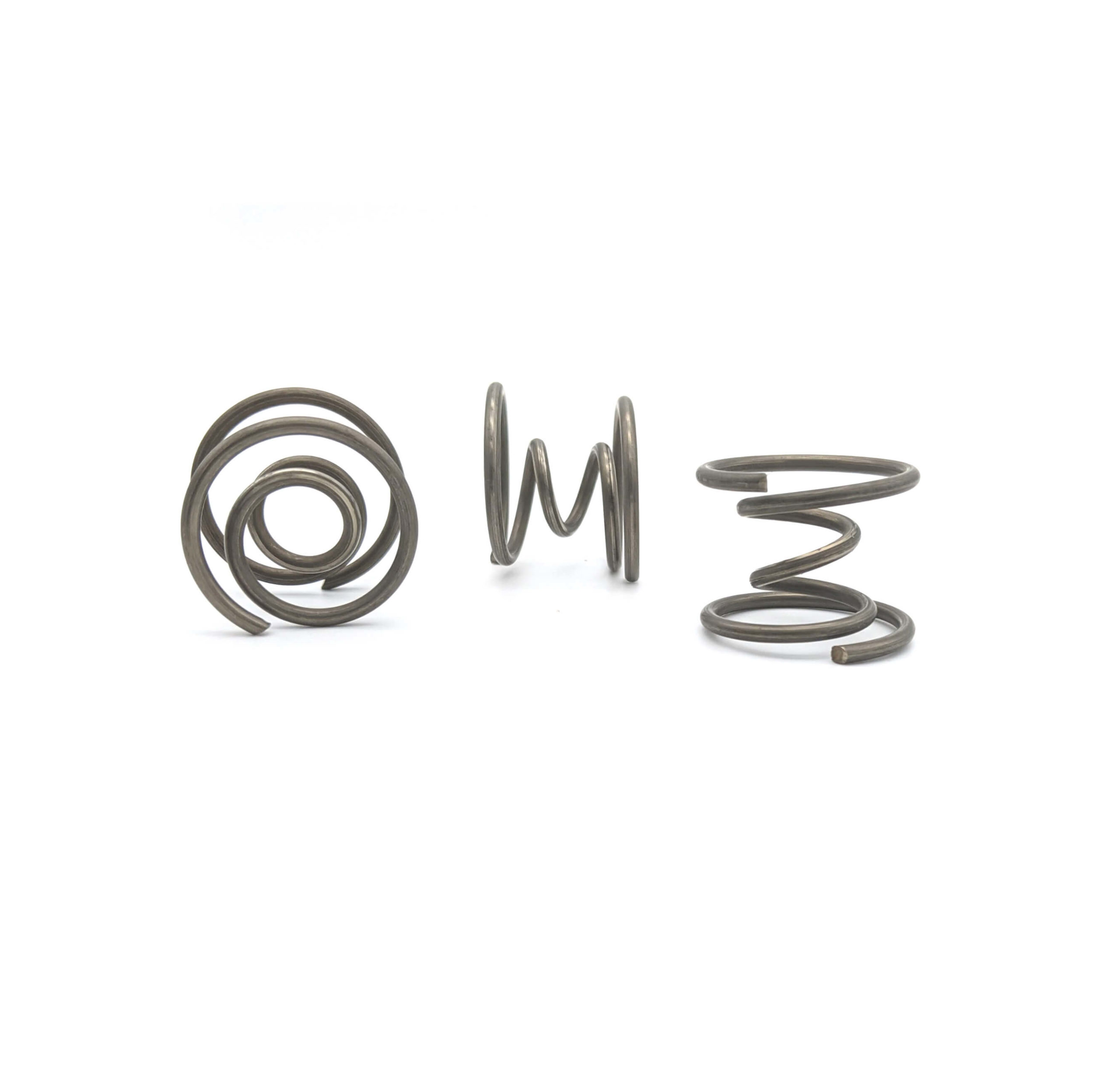

Imagine a spring that, instead of stretching or compressing, twists! That's the essence of a torsion spring. These springs are designed to store and release energy through rotation. When a torque is applied, the spring twists, storing potential energy. As the torque is released, the spring unwinds, converting that stored energy into rotational motion.

The key to understanding torsion springs lies in their shape. They are typically made of a coiled wire that's been carefully formed into a specific configuration. This configuration determines the spring's stiffness, or spring rate, which dictates the amount of torque required to twist the spring a certain angle. This relationship between torque and angle is crucial in designing and selecting the right torsion spring for a specific application.

Small torsion springs, often referred to as mini torsion springs, pack a punch in tiny packages. They offer several advantages that make them invaluable components in various fields:

**1. Precision and Accuracy:** Small torsion springs excel in providing controlled and precise rotational forces. Their compact size allows for fine tuning and adjustment, making them ideal for delicate mechanisms where minute movements matter.

**2. Durability and Strength:** Despite their small size, these springs are remarkably durable and strong. Crafted from high-quality materials like spring steel, they can withstand repeated cycles of twisting and unwinding without losing their effectiveness.

**3. Compactness and Versatility:** Small torsion springs are perfect for applications where space is limited. Their compact design allows them to be easily incorporated into tight spaces, making them ideal for miniaturized devices and assemblies.

**4. Customized Solutions:** Manufacturers can design small torsion springs with specific spring rates, wire diameters, and coil configurations to meet the exact demands of various applications. This customization ensures optimal performance and reliability in a wide range of scenarios.

Small torsion springs, despite their unassuming size, are ubiquitous in our daily lives. They are found in a vast array of products, playing a vital role in ensuring their functionality and smooth operation. Here are just a few examples:

**1. Precision Instruments and Watches:** Think of the delicate hands of a watch, smoothly gliding around the face. These movements are often powered by tiny torsion springs, ensuring accuracy and consistent timekeeping.

**2. Medical Devices:** From medical instruments to surgical equipment, small torsion springs are essential for precise movements and reliable performance. They are used in clamps, forceps, and other devices that require accurate control and delicate handling.

**3. Electronic Devices:** Small torsion springs are essential for the smooth operation of keyboards, buttons, and other components in electronic devices. They provide the necessary tactile feedback and responsiveness for a user-friendly experience.

**4. Automotive Industry:** Small torsion springs are indispensable in automotive components like door latches, hood releases, and window regulators. They ensure the smooth and reliable operation of these critical mechanisms.

**5. Aerospace and Aviation:** These springs find their way into aerospace applications, playing a vital role in landing gear, control systems, and other critical components. Their reliability and ability to withstand extreme environments make them ideal for such demanding applications.

Selecting the appropriate small torsion spring for your application is essential. Here are some factors to consider:

**1. Spring Rate:** The spring rate determines how much torque is required to twist the spring a certain angle. This is a crucial factor in determining the spring's responsiveness and how it will interact with other components in the system.

**2. Wire Diameter:** The thickness of the spring wire plays a role in the spring's strength and durability. Thicker wires provide greater strength, but they may also be heavier and less flexible.

**3. Coil Configuration:** The shape and number of coils in the spring affect its stiffness and its ability to store and release energy. Different coil configurations can be tailored to suit specific applications.

**4. Material:** The material of the spring is critical for its performance and longevity. Spring steel is a common choice due to its strength, resilience, and resistance to fatigue.

When selecting small torsion springs, always prioritize quality. Look for reputable manufacturers who use high-quality materials and rigorous quality control processes. A reliable spring can make all the difference in ensuring the longevity and functionality of your product.

Investing in high-quality small torsion springs can pay off in the long run, reducing the risk of failures, costly repairs, and customer dissatisfaction. Quality springs are built to last, ensuring smooth and reliable operation for years to come.

The world of small torsion springs is constantly evolving. Innovations are emerging to meet the ever-growing demands of modern industries. Here are a few examples:

**1. Precision Springs with Customized Geometries:** Manufacturers are developing advanced techniques to create springs with intricate geometries and extremely precise spring rates. This allows for even finer control and accuracy in demanding applications.

**2. Smart Springs with Integrated Sensors:** Some springs are being integrated with sensors to monitor their performance and provide real-time feedback. This allows for predictive maintenance and improved reliability.

**3. Springs with Reduced Environmental Impact:** There is a growing trend towards using eco-friendly materials and sustainable manufacturing processes in the production of springs. This is driven by the need to reduce the environmental footprint of industries.

Small torsion springs may be tiny, but their impact is immense. They are essential components in a wide range of industries, enabling the smooth operation of countless products that we rely on every day. From the delicate mechanics of a wristwatch to the robust systems in aircraft, small torsion springs continue to play a vital role in shaping our world.

As technology continues to advance, small torsion springs will undoubtedly play an even more significant role in future innovations. Their adaptability, reliability, and ever-increasing precision will ensure their enduring relevance in the years to come. So, next time you encounter a device that operates with smooth, precise motion, remember that a small, often unseen torsion spring might be the secret behind its success.

Small torsion springs are a testament to the ingenuity of engineering. These tiny powerhouses pack a big punch, enabling the smooth operation of countless products and systems. Their precision, durability, and versatility make them essential components in a wide range of applications, from delicate watches to sophisticated medical devices. As technology continues to evolve, small torsion springs will undoubtedly play an even more crucial role in shaping the future of our world. So, next time you encounter a product that operates with smooth, precise motion, take a moment to appreciate the hidden power of a small torsion spring.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.