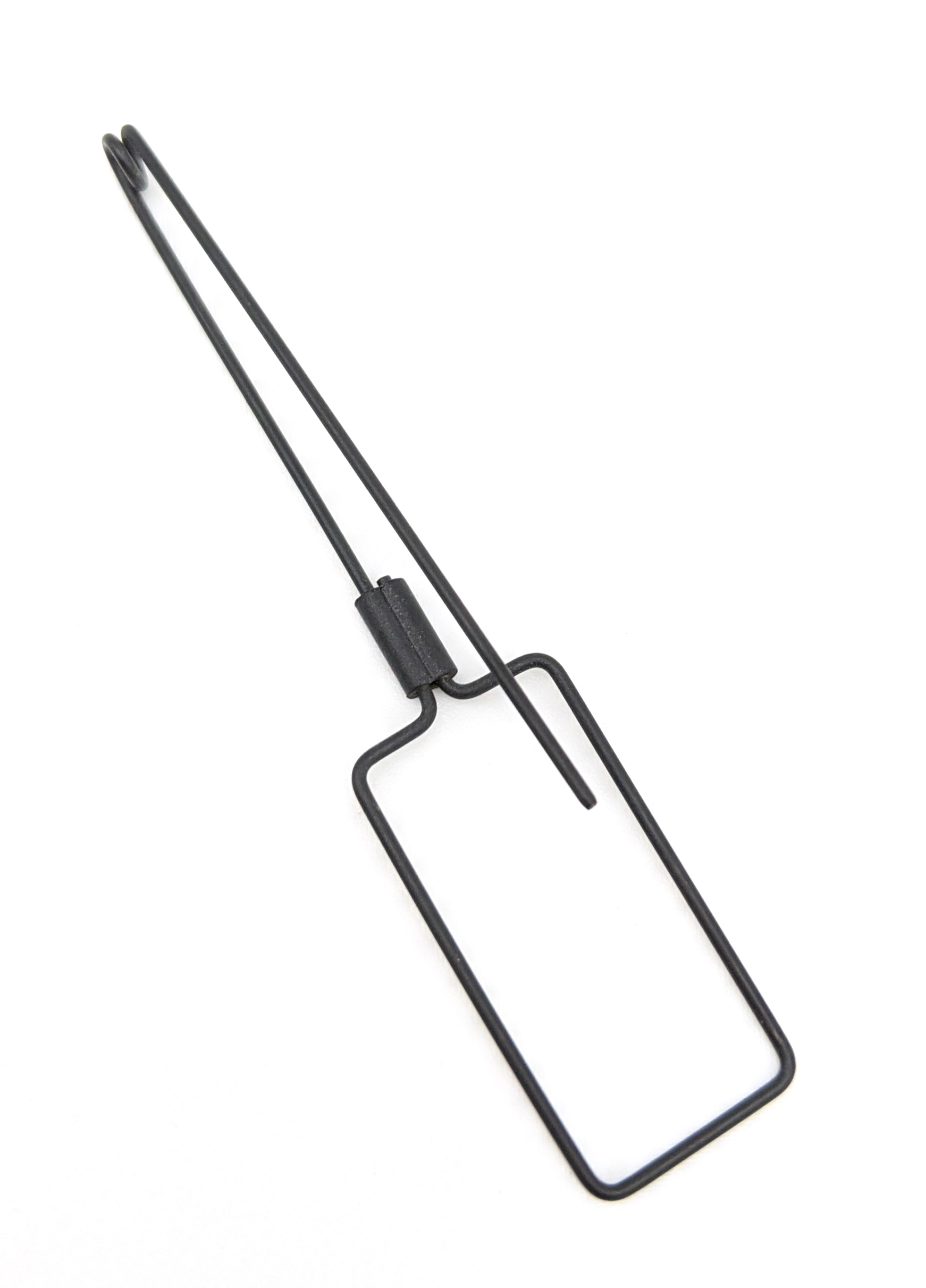

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small torsion springs, often overlooked in the grand scheme of mechanical engineering, play a crucial role in countless devices and systems. These miniature powerhouses, despite their size, pack a surprising

Small torsion springs, often overlooked in the grand scheme of mechanical engineering, play a crucial role in countless devices and systems. These miniature powerhouses, despite their size, pack a surprising amount of torque, making them indispensable for precise movements, controlled adjustments, and delicate applications. From intricate clockwork mechanisms to sophisticated medical devices, small torsion springs are the unsung heroes of countless innovations, quietly ensuring seamless operation and reliable performance.

Small torsion springs, as their name suggests, are compact coiled springs designed to generate torque or rotational force when twisted. Unlike compression or extension springs that push or pull along a linear axis, torsion springs store and release energy through rotational motion. This unique characteristic makes them ideal for applications where precise control and controlled movements are paramount.

The strength and resilience of small torsion springs lie in their construction. Typically crafted from high-quality spring steel, these miniature wonders are carefully engineered to withstand repeated twisting cycles without fatigue or deformation. The spring's diameter, wire gauge, and number of coils all contribute to its spring constant, determining the amount of torque it can generate for a given twist angle.

The world of small torsion springs is remarkably diverse, accommodating a wide range of applications, each with its own unique demands. From the delicate balance of a watch's hairspring to the controlled tension of a medical device, these springs ensure smooth, reliable performance. Let's delve into some of the diverse fields where small torsion springs make their mark:

Small torsion springs are essential components in precision mechanics and instruments. Their ability to provide consistent torque makes them ideal for applications where accuracy is paramount, like:

Small torsion springs also find their place in consumer electronics, where they power the smooth operation of everyday gadgets. Their compact size and precise functionality make them indispensable for:

Beyond the more common applications, small torsion springs also play a vital role in specialized areas like:

Selecting the right small torsion spring for a specific application is crucial to ensure optimal performance and longevity. Key considerations include:

Small torsion springs may be tiny components, but they are the heart of many mechanical systems. Their ability to provide precise torque in a compact package makes them invaluable for countless applications. From intricate clockwork mechanisms to sophisticated medical devices, these miniature powerhouses ensure smooth, reliable performance, showcasing the extraordinary capabilities of engineering at its finest.

Whether you're marveling at the intricate mechanics of a watch or using a smartphone to navigate the world, small torsion springs are working behind the scenes, ensuring smooth and precise movements. These tiny marvels are the unsung heroes of countless innovations, reminding us that even the smallest components can have a significant impact on the world around us.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.