Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

A small spring compression tool is an indispensable tool for any serious DIY enthusiast or professional mechanic. It's a simple yet versatile device that makes compressing and decompressing springs a

A small spring compression tool is an indispensable tool for any serious DIY enthusiast or professional mechanic. It's a simple yet versatile device that makes compressing and decompressing springs a breeze. Whether you're working on automotive repairs, appliance maintenance, or general home projects, having a reliable spring compression tool can save you time, effort, and frustration. In this article, we'll explore the various aspects of this handy tool, from its design and functionality to its applications and benefits.

A spring compression tool, as the name suggests, is designed to compress springs safely and efficiently. The basic principle behind it is the application of force to hold the spring in a compressed state while you work on the component it's attached to. Think of it as a pair of pliers specifically engineered for handling springs. They're typically made from durable materials like steel or aluminum to withstand the force exerted by the spring.

There are two main types of spring compression tools:

Most spring compression tools are adjustable, allowing you to work on springs of varying sizes. You'll find variations in the type of handle used, from basic hand-operated models to those with adjustable handles or even powered models for extra force. The specific design and features depend on the manufacturer and the intended purpose of the tool.

Using a dedicated spring compression tool offers a number of advantages, making it a valuable addition to any toolbox:

Selecting the right spring compression tool is essential for achieving optimal results and ensuring your safety. Here are some factors to consider when making your choice:

Once you have your spring compression tool, here are some tips to ensure its safe and effective use:

A small spring compression tool is a valuable asset for anyone who works with springs regularly. It provides safety, ease of use, and efficiency, simplifying a potentially hazardous task. By following the tips and guidelines discussed in this article, you can utilize this tool effectively and safely, enhancing your DIY projects, repairs, and overall mechanical proficiency.

When it comes to working with springs, a small spring compression tool is an essential companion. It elevates safety and efficiency, allowing you to focus on the task at hand with confidence and accuracy. Whether you're a professional mechanic, a dedicated DIY enthusiast, or simply a homeowner tackling a repair project, investing in a reliable spring compression tool is a worthwhile decision. It's a small tool with a big impact, making spring compression tasks a breeze and your workshop a safer and more efficient environment.

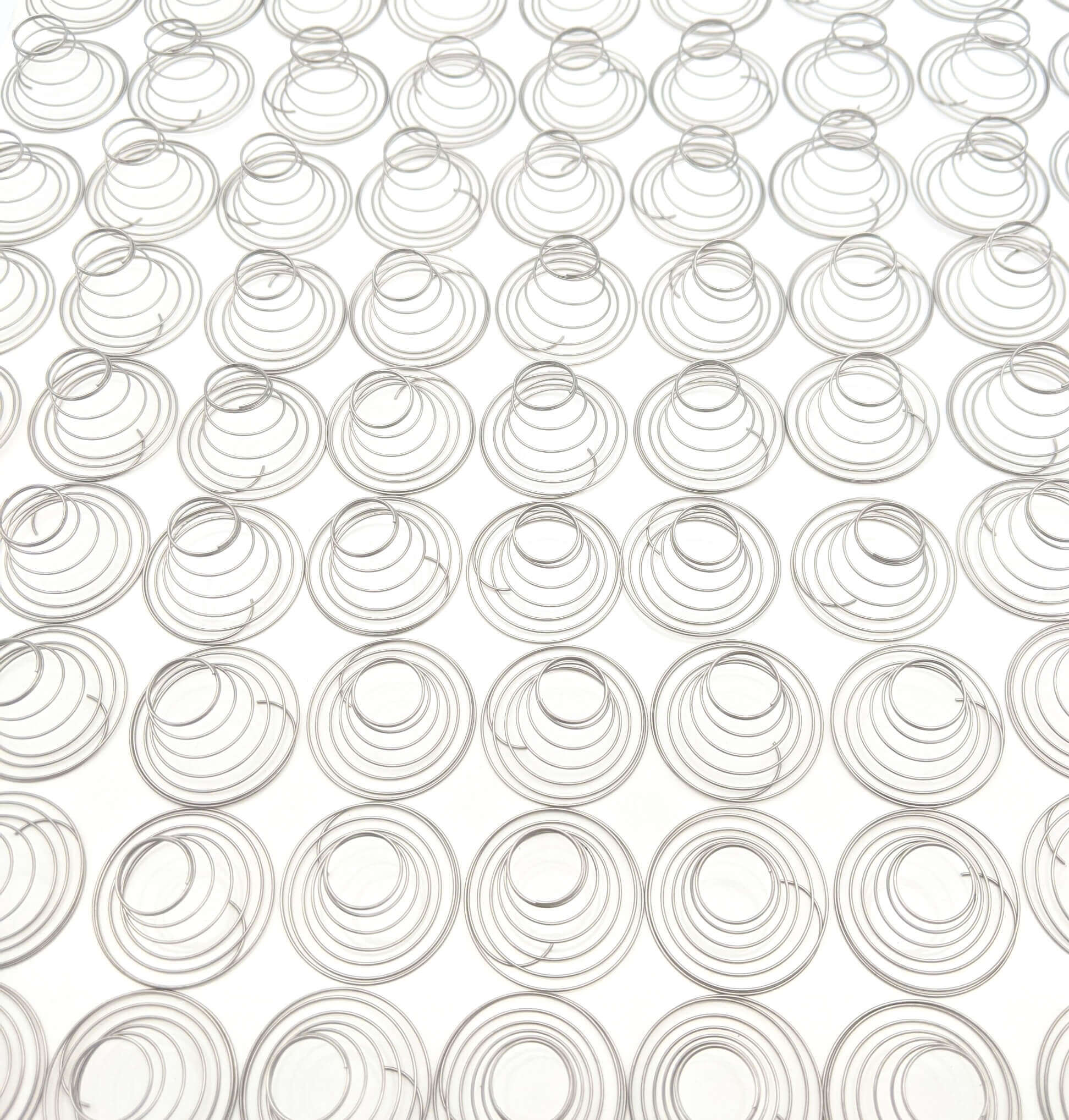

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.