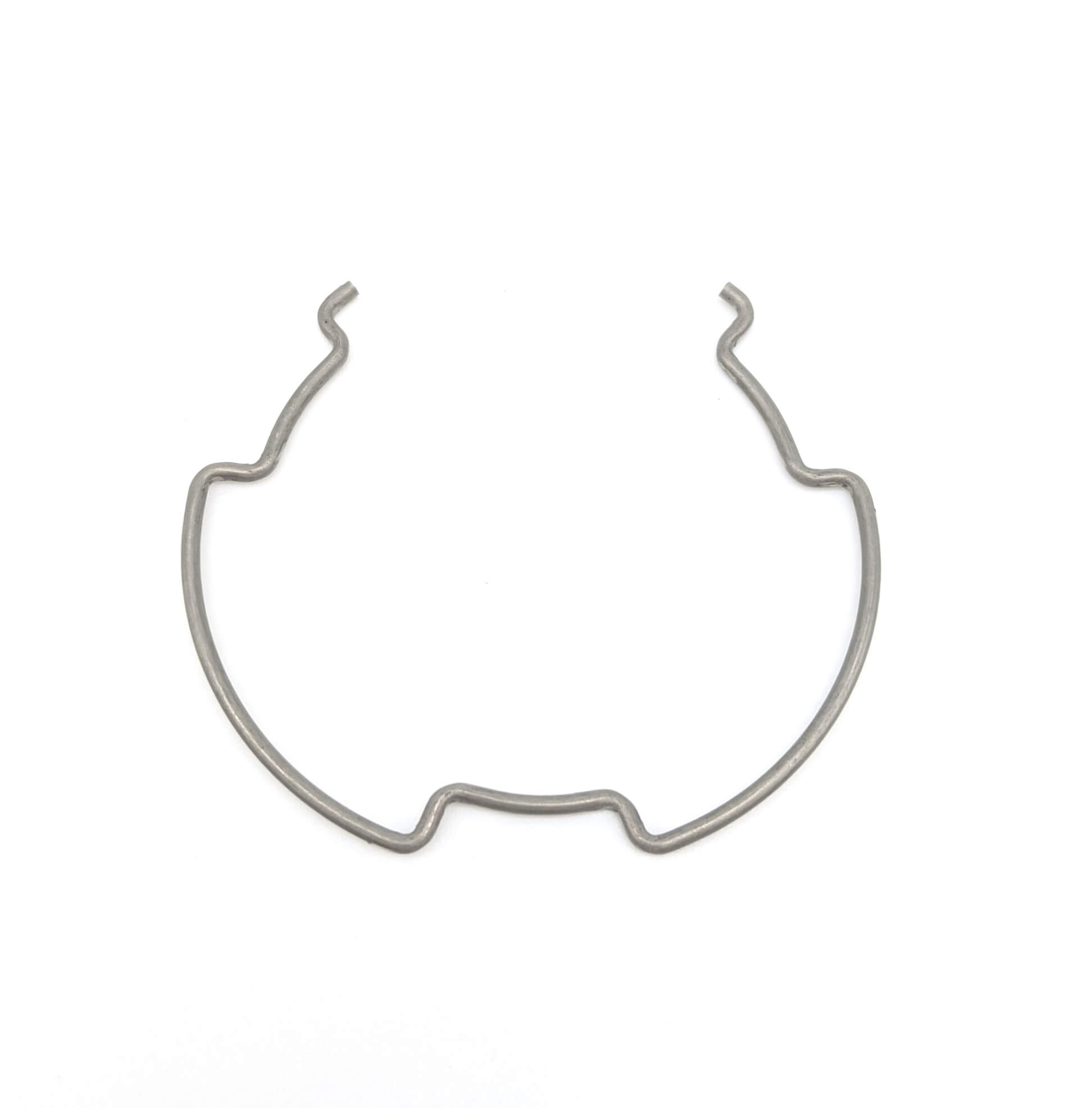

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Often overlooked, small compression springs are the unsung heroes of countless mechanical systems. These miniature marvels, with their seemingly simple design, pack a punch when it comes to storing and

Often overlooked, small compression springs are the unsung heroes of countless mechanical systems. These miniature marvels, with their seemingly simple design, pack a punch when it comes to storing and releasing energy, providing support, and maintaining tension in a wide range of applications. From delicate medical devices to robust industrial machinery, small compression springs play a crucial role in ensuring smooth, reliable operation.

Imagine a tiny, coiled wire that can exert incredible force when compressed. That's the essence of a small compression spring, a seemingly simple yet remarkably versatile mechanical component. These springs are typically made from high-quality spring steel, though other materials like stainless steel, phosphor bronze, or music wire are also employed for specific applications. Their compact size and remarkable resilience make them perfect for situations where space is limited and precision is paramount.

The beauty of small compression springs lies in their ability to store and release energy in a controlled manner. When compressed, they absorb energy and resist the force applied. Upon release, they spring back to their original shape, converting the stored energy into mechanical motion. This fundamental principle forms the foundation for a vast array of applications in diverse industries.

You might be surprised to learn how frequently these little powerhouses are used in our everyday lives. Let's explore some key applications where small compression springs shine:

1. Medical Devices: From delicate surgical instruments to the intricate mechanisms of hearing aids, small compression springs ensure precision and reliability. They provide the necessary force for smooth operation, enabling delicate procedures and enhancing patient comfort. Their biocompatibility and resistance to corrosion make them ideal for applications within the human body.

2. Electronics and Appliances: Small compression springs are indispensable in electronics and household appliances. They are found in keyboards, mouse buttons, and other mechanical switches, providing the tactile feedback we rely on. They also assist in the smooth operation of various mechanisms within washing machines, refrigerators, and other appliances.

3. Automotive: The automotive industry heavily relies on small compression springs for a variety of functions. They power the clutch and brake pedals, provide tension in seat belts, and assist with the operation of door latches. Their durability and resistance to wear and tear make them essential components for reliable automotive performance.

4. Aerospace: In the demanding environment of aerospace, small compression springs play a vital role in various applications. They are used in control systems, landing gear, and other critical components, ensuring smooth operation and reliable performance under extreme conditions.

5. Industrial Machinery: Small compression springs are essential in a wide range of industrial applications. They are used in presses, conveyors, robotics, and various manufacturing processes, providing the necessary force for reliable operation. Their durability and resistance to fatigue make them ideal for high-stress environments.

While all small compression springs store and release energy, their specific characteristics vary greatly, making it essential to choose the right one for your application. Key factors to consider include:

1. Wire Diameter: The diameter of the spring wire determines its strength and load capacity. Thicker wires result in stronger springs capable of handling heavier loads.

2. Coil Diameter: The diameter of the coil influences the spring's deflection and overall size. Larger coils generally result in greater deflection and a larger overall spring size.

3. Number of Coils: The number of coils directly impacts the spring's stiffness. More coils result in a stiffer spring, while fewer coils lead to a softer spring.

4. Material: Different materials offer varying properties, influencing the spring's strength, corrosion resistance, and temperature tolerance. Steel is often preferred for its high strength, while stainless steel offers superior corrosion resistance.

5. Spring Rate: The spring rate, measured in pounds per inch (lb/in), represents the force required to compress the spring by a specific distance. This value is critical for determining how much force the spring will exert.

Small compression springs are not static; they are constantly evolving. Advances in materials science and manufacturing processes are leading to the development of even smaller, stronger, and more durable springs. These advancements are opening up new possibilities for miniaturization, enabling the development of innovative devices and systems.

Furthermore, advancements in spring design software are simplifying the process of selecting and designing small compression springs. These tools allow engineers to quickly optimize spring parameters, ensuring optimal performance for specific applications.

From the intricate workings of medical devices to the robust functionality of industrial machinery, small compression springs play a critical role in our modern world. These seemingly insignificant components pack a powerful punch, enabling precision, efficiency, and reliability across a wide range of applications. Their versatility, durability, and continuous evolution ensure that small compression springs will continue to be essential components in the future of engineering and technology.

The next time you encounter a device or system that operates with smooth precision, remember the small compression springs quietly working behind the scenes. These tiny powerhouses, often overlooked, are the unsung heroes of countless innovations, shaping our world in countless ways.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.