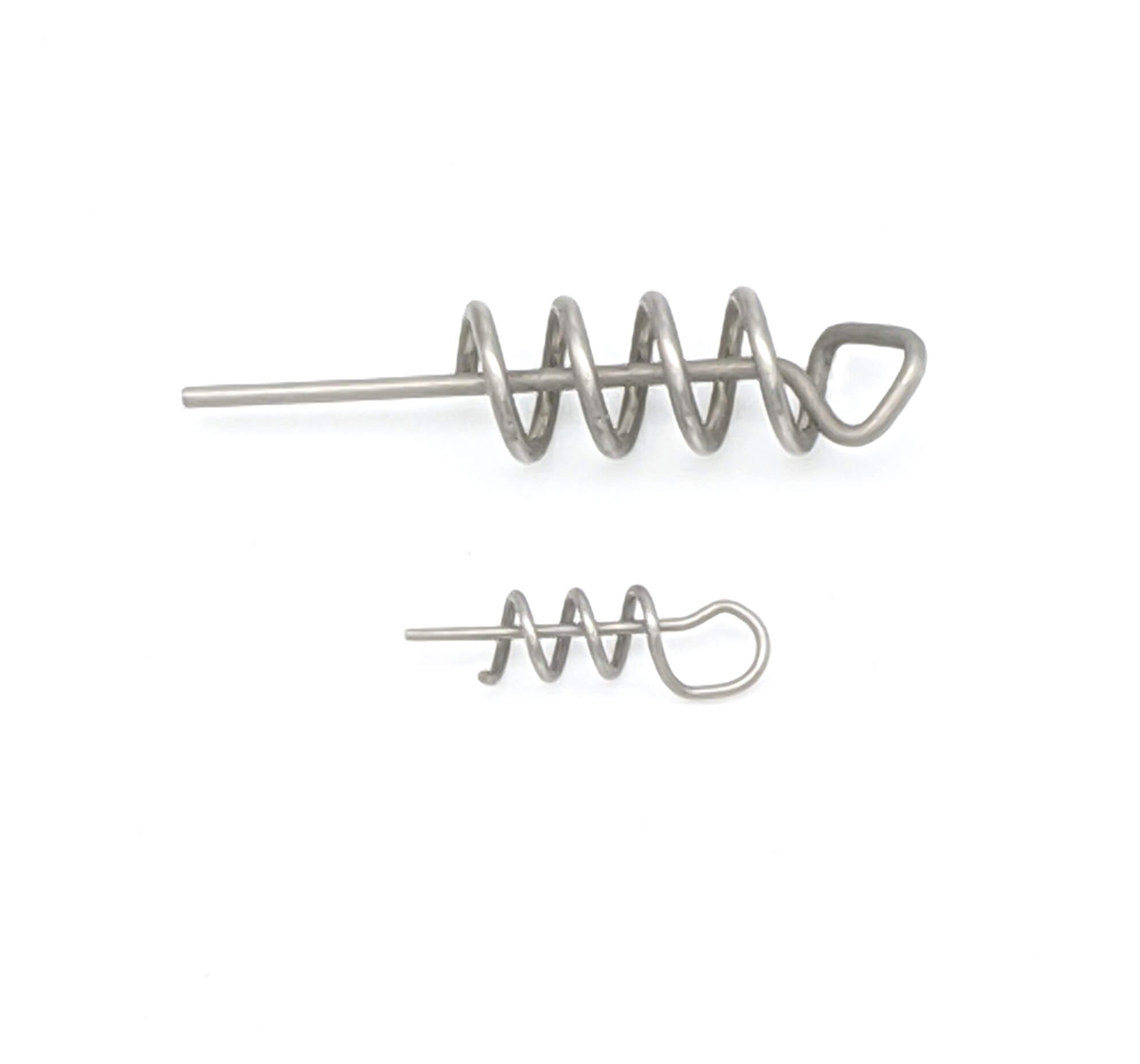

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small compression springs, despite their diminutive size, are often the unsung heroes of countless everyday devices. They are the hidden force that allows us to smoothly open a pen, retract

Small compression springs, despite their diminutive size, are often the unsung heroes of countless everyday devices. They are the hidden force that allows us to smoothly open a pen, retract a retractable pen, or even enjoy the satisfying click of a ballpoint pen. From the intricate workings of a watch to the complex mechanics of a car, these tiny springs play a vital role in ensuring smooth, reliable operation. This article delves into the fascinating world of small compression springs, exploring their design, materials, applications, and the remarkable impact they have on our daily lives.

Small compression springs, as the name suggests, are designed to withstand compressive forces, becoming shorter when a load is applied. They are typically made from wire with a diameter of less than 0.1 inches (2.5 mm), offering a wide range of sizes and configurations to fit various applications. These compact marvels are crafted from a variety of materials, including spring steel, stainless steel, and even exotic alloys like beryllium copper, each chosen for its specific properties to meet the needs of the application.

The beauty of small compression springs lies in their versatility. They can be found in an array of devices, from the mundane to the extraordinary. Imagine the simple act of opening a ballpoint pen; the click you hear is the result of a small compression spring releasing its stored energy. In a retractable pen, the spring ensures the smooth retraction of the writing tip. Even the springy action of a mechanical pencil relies on a small compression spring.

These tiny springs are also integral to the workings of intricate mechanisms like watches and clocks. The mainspring, a coiled spring that stores energy, is essential for powering the gears and hands of a watch. In clocks, small compression springs are often used to provide a steady return force for the hands, ensuring accurate timekeeping.

Beyond everyday objects, small compression springs find applications in a wide range of industries. In the automotive industry, they are crucial for valve operation, suspension systems, and other vital components. In electronics, they are used in switches, connectors, and other delicate parts. Their presence can be felt in medical devices, toys, and countless other products we interact with daily.

The design of a small compression spring is a delicate balance of factors, including wire diameter, coil diameter, number of coils, and material properties. These factors determine the spring's stiffness, which is measured by its spring rate, or the amount of force required to compress the spring by a given distance. A higher spring rate signifies a stiffer spring that requires more force to compress. The spring rate is crucial for ensuring the spring functions correctly in its intended application.

The process of designing a small compression spring involves understanding the forces it will encounter and the desired response. For instance, a spring used in a pen needs to be stiff enough to retract the pen's writing tip, but not so stiff that it makes the pen feel awkward to use. Conversely, a spring used in a watch's mainspring needs to store a significant amount of energy while remaining compact and durable.

The material chosen for a small compression spring is critical to its performance. Spring steel, a common material, is known for its strength, resilience, and ability to withstand repeated cycles of compression and release. However, for applications requiring resistance to corrosion or electrical conductivity, other materials like stainless steel or beryllium copper might be preferred.

Stainless steel, with its excellent corrosion resistance, is ideal for springs exposed to harsh environments, such as those found in medical devices or automotive parts. Beryllium copper, known for its high conductivity and strength, is used in electronics and applications where electrical conductivity is essential.

The applications of small compression springs are as diverse as the industries they serve. Here are just a few examples:

Small compression springs may seem insignificant, but their impact on our lives is undeniable. These tiny components are the backbone of countless devices and technologies that we rely on every day. They are the unsung heroes of modern technology, silently working behind the scenes to make our world a little bit smoother and a lot more efficient.

The next time you pick up a pen, flip a switch, or admire the intricate workings of a watch, take a moment to appreciate the small compression springs that make it all possible. They are a testament to the power of engineering and the ingenuity of human innovation. The world of small compression springs is a fascinating one, filled with remarkable feats of design and engineering. These tiny powerhouses may be small, but their impact on our lives is anything but.

Small compression springs are a testament to the ingenuity of engineering. They are the unsung heroes of countless products, proving that even the smallest components can have a significant impact on our lives. From the everyday convenience of a pen to the intricate workings of complex machinery, these miniature marvels silently contribute to the efficiency and functionality of our modern world. Their seemingly simple design belies their remarkable versatility and importance, solidifying their place as essential elements of our technological landscape.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.