Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Small compression springs, often overlooked for their size, play a crucial role in countless everyday objects. From the simple act of opening a pen to the complex workings of a

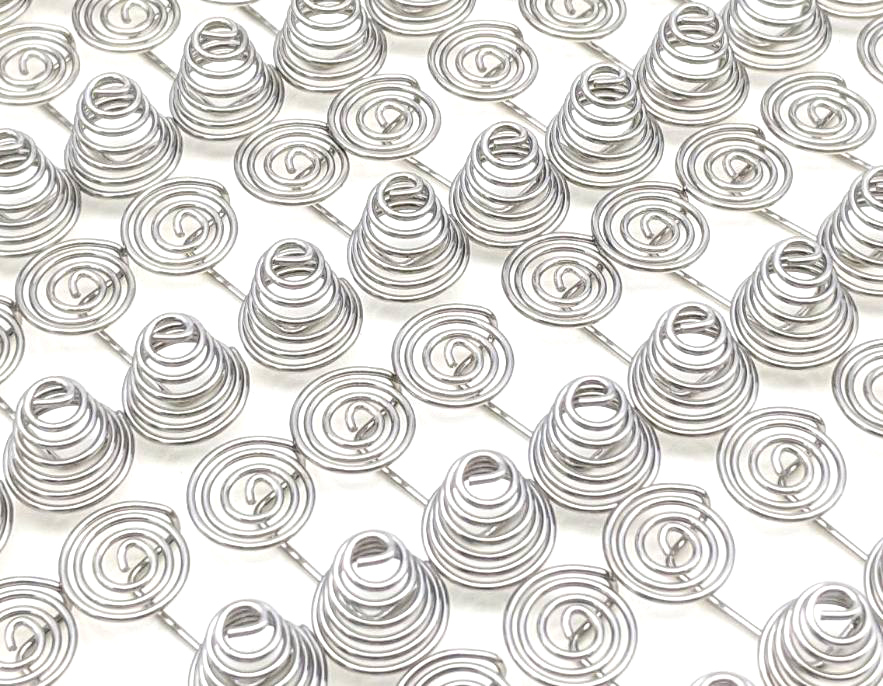

Small compression springs, often overlooked for their size, play a crucial role in countless everyday objects. From the simple act of opening a pen to the complex workings of a smartphone, these tiny coiled wonders provide the force necessary for a multitude of functions. Their compact size belies their remarkable strength and versatility, making them essential components in various industries. But what exactly are small compression springs, and how do they work their magic? Let's delve into the fascinating world of these miniature powerhouses.

Imagine a tightly wound coil of wire, capable of pushing back with surprising force when compressed. That's essentially what a small compression spring is. These springs are designed to resist compression, becoming shorter when a load is applied and returning to their original length when the load is removed. This ability to store and release energy is what makes them so useful.

Small compression springs are typically made from spring steel, a material known for its elasticity and resilience. The wire is coiled around a mandrel to form the spring's shape, and the diameter of the wire and the number of coils determine the spring's stiffness or spring rate. A higher spring rate indicates a stiffer spring that requires more force to compress.

The applications of small compression springs are incredibly diverse, encompassing a wide range of industries. Here are a few notable examples:

Small compression springs are ubiquitous in our daily lives. They power the retractable mechanisms in ballpoint pens, allowing for smooth ink flow. They provide the springy action in clothespins, helping to secure our laundry. They even play a critical role in the satisfying 'click' of a click pen, adding a touch of tactile delight to our writing experience.

Under the hood of every car, small compression springs are essential for a variety of functions. They provide the tension needed to keep the valve springs in place, ensuring proper engine operation. They also power the return mechanism in clutch pedals, allowing for smooth gear changes. And let's not forget the humble windshield wipers, where small compression springs ensure a consistent and reliable sweep.

The miniaturization of electronics has led to an increased demand for small compression springs in various devices. They provide the spring action in keyboard buttons, ensuring a responsive typing experience. They also power the push-button mechanisms in remote controls, making it easy to navigate through our favorite channels. And in household appliances, small compression springs can be found in everything from washing machines to refrigerators, ensuring smooth and efficient operation.

Selecting the appropriate small compression spring for a specific application requires careful consideration of several factors:

* **Spring Rate:** The stiffness of the spring is determined by its spring rate, measured in force per unit deflection. Choosing the right spring rate ensures proper function and avoids over-compression or excessive strain.

* **Spring Length:** The length of the spring is crucial for determining the amount of compression required. Selecting the appropriate length ensures optimal performance and avoids any limitations in movement.

* **Material:** The material of the spring plays a significant role in its strength, durability, and resistance to corrosion. Choosing a suitable material ensures long-lasting performance and reliability.

* **Environment:** The operating environment of the spring can affect its performance and longevity. Factors such as temperature, humidity, and chemical exposure need to be considered when selecting a spring material.

Small compression springs may be tiny, but their precision and quality are paramount. Any deviation from the specified dimensions or material properties can have a significant impact on the spring's performance and reliability. That's why it's essential to work with reputable manufacturers who prioritize accuracy and meticulous craftsmanship.

As technology continues to advance, the demand for small compression springs is only expected to increase. The development of new materials and manufacturing techniques will further enhance their capabilities, enabling them to play an even more vital role in a wide range of applications. From medical devices to aerospace engineering, small compression springs are poised to continue driving innovation and shaping the future.

Small compression springs, though often hidden from view, are vital components in countless everyday objects. Their remarkable strength and versatility make them indispensable in various industries. By understanding their function, applications, and selection criteria, we can better appreciate the importance of these miniature powerhouses. As technology continues to evolve, small compression springs will undoubtedly play an even greater role in shaping our future, reminding us that even the smallest things can have a profound impact.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.