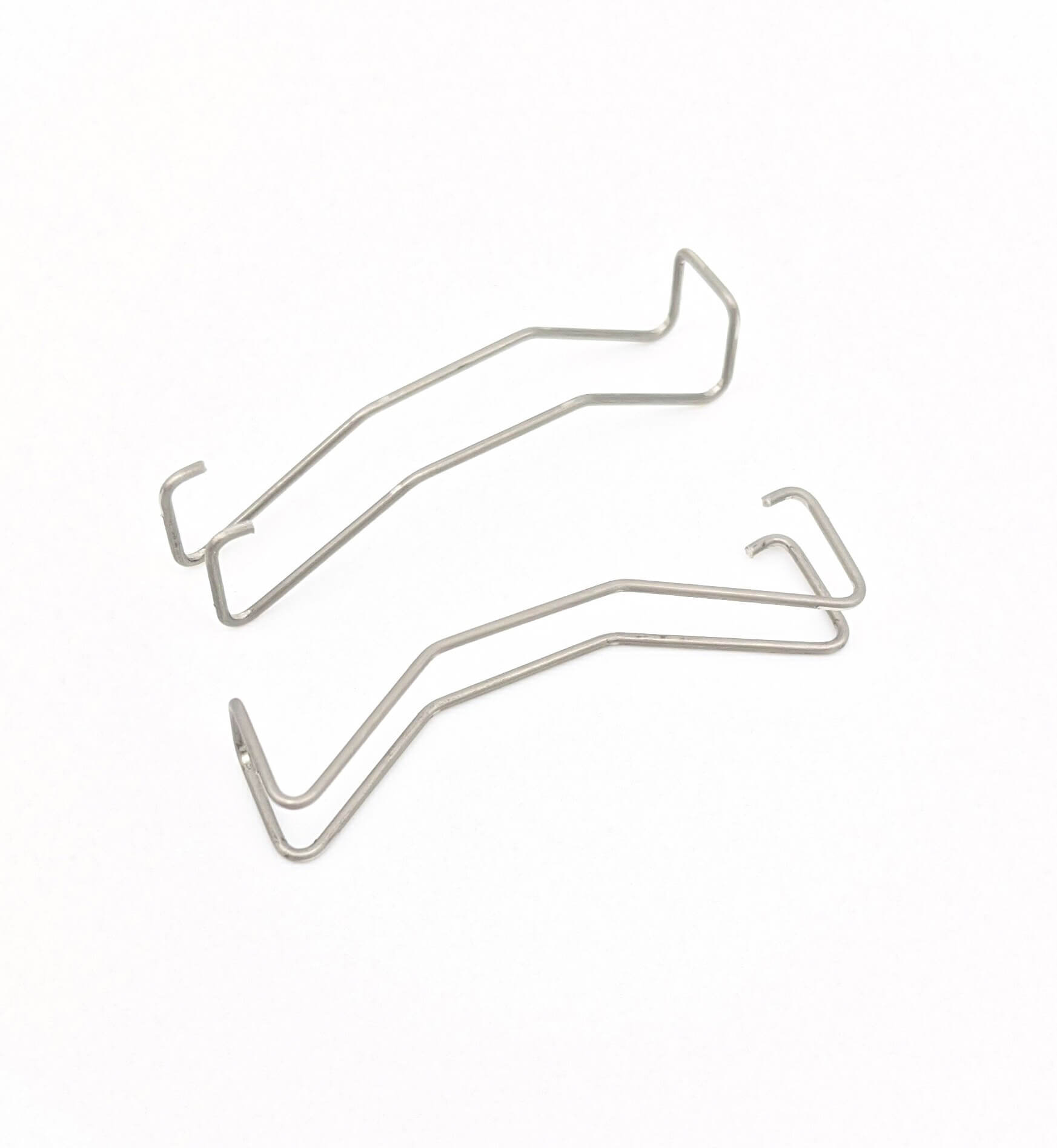

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the vast world of engineering, small compression springs might seem insignificant, but their impact is profound. These tiny, coiled wonders are the unsung heroes of countless devices, from intricate

In the vast world of engineering, small compression springs might seem insignificant, but their impact is profound. These tiny, coiled wonders are the unsung heroes of countless devices, from intricate medical instruments to everyday household items. Their ability to store and release energy, providing resistance and support, makes them indispensable in various applications. This article will delve into the fascinating world of small compression springs, exploring their design, materials, applications, and the reasons why they are so essential in our modern world.

Imagine a tiny coiled wire, compressed and then released, propelling a tiny piston or holding a delicate mechanism in place. That's the essence of a small compression spring. These springs are designed to absorb and release energy, resisting compressive forces while maintaining their shape. They are typically made from high-quality spring steel, known for its resilience and ability to withstand repeated compression cycles.

The design of a small compression spring is crucial for its performance. Factors like the wire diameter, coil diameter, number of coils, and spring index all play a vital role in determining the spring's stiffness, load capacity, and overall functionality. A smaller wire diameter results in a more flexible spring, while a larger wire diameter yields a stiffer spring. The number of coils also impacts the spring's stiffness, with more coils leading to a higher spring rate.

The material used in manufacturing small compression springs is a key determinant of their performance and longevity. While spring steel is the most common choice, other materials are employed for specific applications. Here are some popular options:

The compact size and reliable performance of small compression springs make them incredibly versatile. They are used in a wide range of industries, including:

Small compression springs offer several advantages that make them invaluable in countless applications:

Selecting the right small compression spring for a particular application requires careful consideration. Factors to consider include:

Small compression springs may be tiny, but their impact on our world is undeniable. These resilient, reliable, and versatile components play a vital role in countless applications, contributing to the smooth operation of devices that shape our lives. From the intricate mechanisms of medical instruments to the everyday conveniences of household appliances, small compression springs are the silent heroes, working tirelessly behind the scenes to make our world run better. Next time you encounter a device powered by a spring, take a moment to appreciate the remarkable engineering that makes these miniature marvels so essential.

Small compression springs are a testament to the power of precision engineering. Their ability to store and release energy in a compact form makes them indispensable for countless applications. While they may be often unseen, their impact on our modern world is immense. So next time you encounter a small compression spring, take a moment to appreciate the tiny miracle that makes so much possible.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.