Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

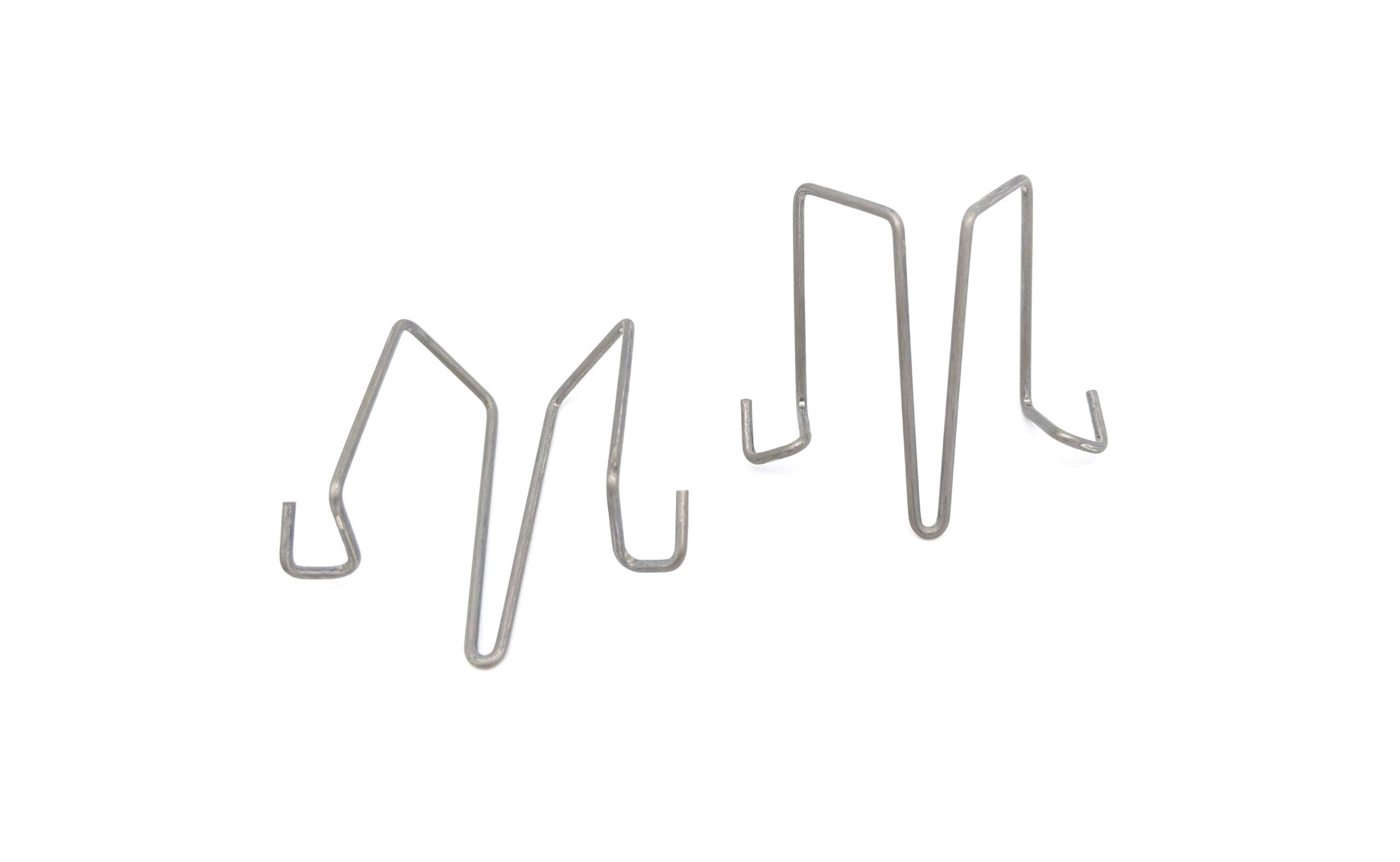

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

RDU WAV springs, also known as wave springs, are a type of mechanical spring that offer unique advantages over traditional coil springs. Their distinctive wave-like design provides superior performance in

RDU WAV springs, also known as wave springs, are a type of mechanical spring that offer unique advantages over traditional coil springs. Their distinctive wave-like design provides superior performance in terms of space efficiency, load capacity, and fatigue resistance. This comprehensive guide will delve into the intricacies of RDU WAV springs, exploring their benefits, applications, and considerations for selecting the right spring for your specific requirements.

RDU WAV springs, often referred to as wave springs, are a specialized type of spring characterized by their unique wave-like construction. Unlike traditional coil springs, WAV springs consist of a series of interconnected waves that are stacked upon each other. This distinctive design provides a number of advantages, including:

1. **Space Efficiency:** WAV springs are remarkably compact, offering significant space savings compared to their coil spring counterparts. This makes them ideal for applications where space is limited, such as in tight-fitting machinery or electronic devices.

2. **High Load Capacity:** Despite their compact size, WAV springs are capable of handling substantial loads. This strength is attributed to their wave-like configuration, which distributes the load evenly across the spring's surface.

3. **Fatigue Resistance:** WAV springs are exceptionally resistant to fatigue, meaning they can withstand repeated compression and extension cycles without experiencing premature failure. This makes them suitable for applications requiring long-term reliability and durability.

4. **Stable Spring Rate:** WAV springs maintain a consistent spring rate throughout their compression cycle, ensuring predictable and reliable performance. This is particularly beneficial in applications demanding precise force control.

RDU WAV springs find widespread applications across various industries, including:

1. **Automotive:** WAV springs are often used in automotive suspension systems, clutch mechanisms, and valve actuation systems. Their space-saving design and high load capacity make them a popular choice in these applications.

2. **Aerospace:** WAV springs are employed in aircraft components, including landing gear, control systems, and fuel systems. Their lightweight construction and high fatigue resistance make them ideal for aerospace applications.

3. **Electronics:** WAV springs are used in various electronic devices, such as connectors, switches, and actuators. Their compact size and stable spring rate ensure precise operation and long-term reliability.

4. **Medical Devices:** WAV springs find applications in medical devices, including prosthetic limbs, surgical instruments, and medical implants. Their biocompatibility and durability make them suitable for use in the human body.

Selecting the right RDU WAV spring for your needs requires careful consideration of several factors, including:

1. **Load Capacity:** Determine the maximum load the spring needs to withstand. This will dictate the spring's material, dimensions, and number of waves.

2. **Spring Rate:** Choose a spring with a suitable spring rate to provide the desired force and displacement. This will depend on the specific application and the desired response.

3. **Space Constraints:** Consider the available space for the spring. WAV springs offer exceptional space efficiency, but it's essential to ensure they fit within your design limitations.

4. **Environmental Conditions:** Take into account the operating environment, including temperature, humidity, and potential corrosive agents. Selecting the appropriate material and protective coatings is crucial.

RDU WAV springs are a versatile and highly efficient solution for a wide range of applications. Their unique design and superior performance make them a reliable choice for demanding engineering tasks. By understanding their benefits, applications, and selection criteria, engineers and designers can harness the full potential of these remarkable springs to enhance their projects.

Whether you're designing a compact automotive suspension system, a lightweight aircraft component, or a precise electronic device, RDU WAV springs offer an exceptional solution. Their space efficiency, load capacity, fatigue resistance, and stable spring rate make them an invaluable asset for engineers seeking reliable and high-performing springs. By carefully considering your application requirements and selecting the right WAV spring, you can ensure optimal performance and long-term durability in your designs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.