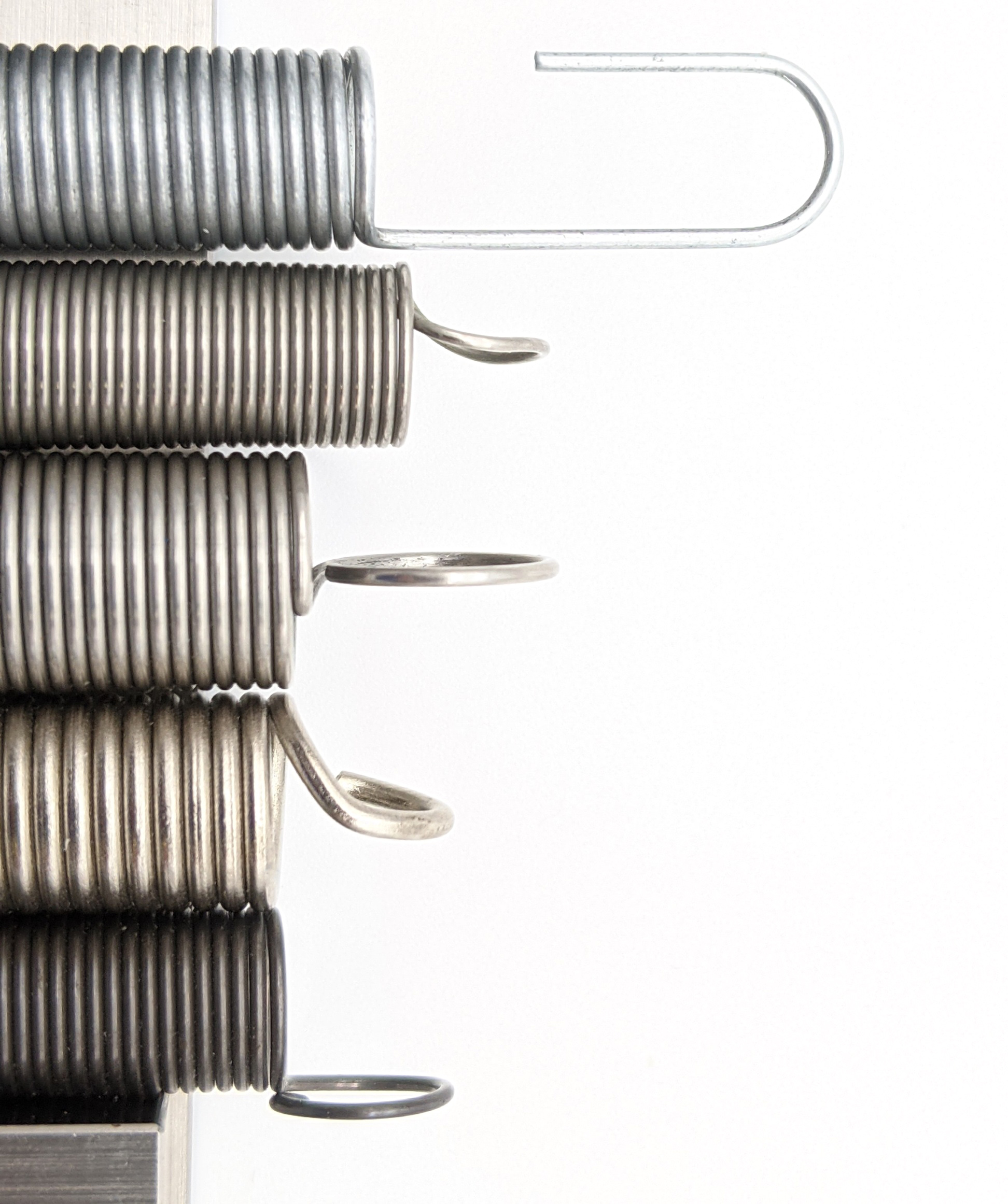

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

RAR coil springs, also known as rare earth alloy coil springs, are a specialized type of spring that offers exceptional performance characteristics. These springs are engineered with rare earth alloys,

RAR coil springs, also known as rare earth alloy coil springs, are a specialized type of spring that offers exceptional performance characteristics. These springs are engineered with rare earth alloys, which are renowned for their high strength-to-weight ratio, exceptional corrosion resistance, and excellent temperature stability. This article delves into the fascinating world of RAR coil springs, exploring their design principles, diverse applications, and the compelling advantages they offer compared to conventional springs.

RAR coil springs, a captivating innovation in the realm of spring technology, are crafted from rare earth alloys. These alloys, distinguished by their unique chemical composition, impart remarkable properties to the springs, setting them apart from their traditional counterparts. Rare earth elements, known for their exceptional strength and resilience, are carefully blended to create an alloy that exhibits remarkable strength-to-weight ratio, exceptional corrosion resistance, and remarkable temperature stability. These attributes make RAR coil springs an ideal choice for demanding applications where performance and reliability are paramount.

The design of RAR coil springs is a meticulous process that demands a deep understanding of material science, spring mechanics, and the specific requirements of the application. The design parameters encompass the spring's diameter, wire diameter, number of coils, spring rate, and free length. These parameters are carefully chosen to optimize the spring's performance, ensuring it meets the desired force, deflection, and durability specifications.

The selection of the rare earth alloy is crucial, as it determines the spring's overall performance characteristics. Engineers meticulously analyze the specific application to select the most appropriate alloy, considering factors such as required strength, corrosion resistance, and operating temperature range. The alloy's composition plays a pivotal role in shaping the spring's resilience, its ability to withstand harsh environments, and its longevity under demanding conditions.

RAR coil springs find widespread applications in a diverse range of industries, due to their exceptional properties. Their high strength and resilience make them particularly suitable for applications where heavy loads or extreme stresses are encountered. In automotive applications, RAR coil springs are employed in suspension systems, providing superior ride comfort and handling. They are also utilized in aerospace components, where lightweight construction and exceptional performance are essential. RAR coil springs are a vital component in various industrial machinery, from heavy-duty equipment to precision instruments.

RAR coil springs are also used in medical devices, where their biocompatibility and resistance to corrosion are critical factors. Their exceptional strength and precision allow them to be used in surgical instruments, prosthetics, and other medical devices. The combination of high strength, corrosion resistance, and temperature stability makes RAR coil springs an ideal choice for applications where reliability and performance are paramount.

RAR coil springs offer a compelling array of advantages over conventional springs, making them the preferred choice in many demanding applications. Their high strength-to-weight ratio allows for the use of lighter materials without compromising performance. This translates into significant weight savings, particularly in applications where weight is a critical factor, such as aerospace and automotive industries. RAR coil springs demonstrate exceptional corrosion resistance, making them an ideal choice for applications where exposure to harsh environments is a concern, such as marine environments or industrial settings. They retain their strength and elasticity even at high temperatures, making them suitable for applications involving extreme heat, such as in high-performance engines or furnaces.

RAR coil springs also exhibit excellent fatigue resistance, ensuring that they can withstand repeated cycles of loading and unloading without experiencing premature failure. This durability is crucial in applications where the springs experience constant cyclic loading, such as in automotive suspension systems. RAR coil springs offer exceptional accuracy and precision, due to the meticulous manufacturing processes and the inherent stability of the rare earth alloys. This makes them ideal for use in sensitive instruments and medical devices where precision is paramount.

RAR coil springs, a testament to the ingenuity of engineering and the exceptional properties of rare earth alloys, have revolutionized the realm of spring technology. Their remarkable strength, corrosion resistance, temperature stability, and durability make them the preferred choice in diverse applications, ranging from automotive and aerospace to medical and industrial settings. As technology continues to evolve, we can expect to see even more innovative applications of RAR coil springs, pushing the boundaries of performance and reliability in diverse industries.

The exceptional properties and versatility of RAR coil springs have made them an indispensable component in a wide range of industries. From aerospace to medical devices, these springs deliver unparalleled performance, reliability, and longevity, solidifying their place as a leading solution for demanding applications. As technology continues to advance, we can expect to see even more groundbreaking uses for RAR coil springs, shaping the future of engineering and design.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.