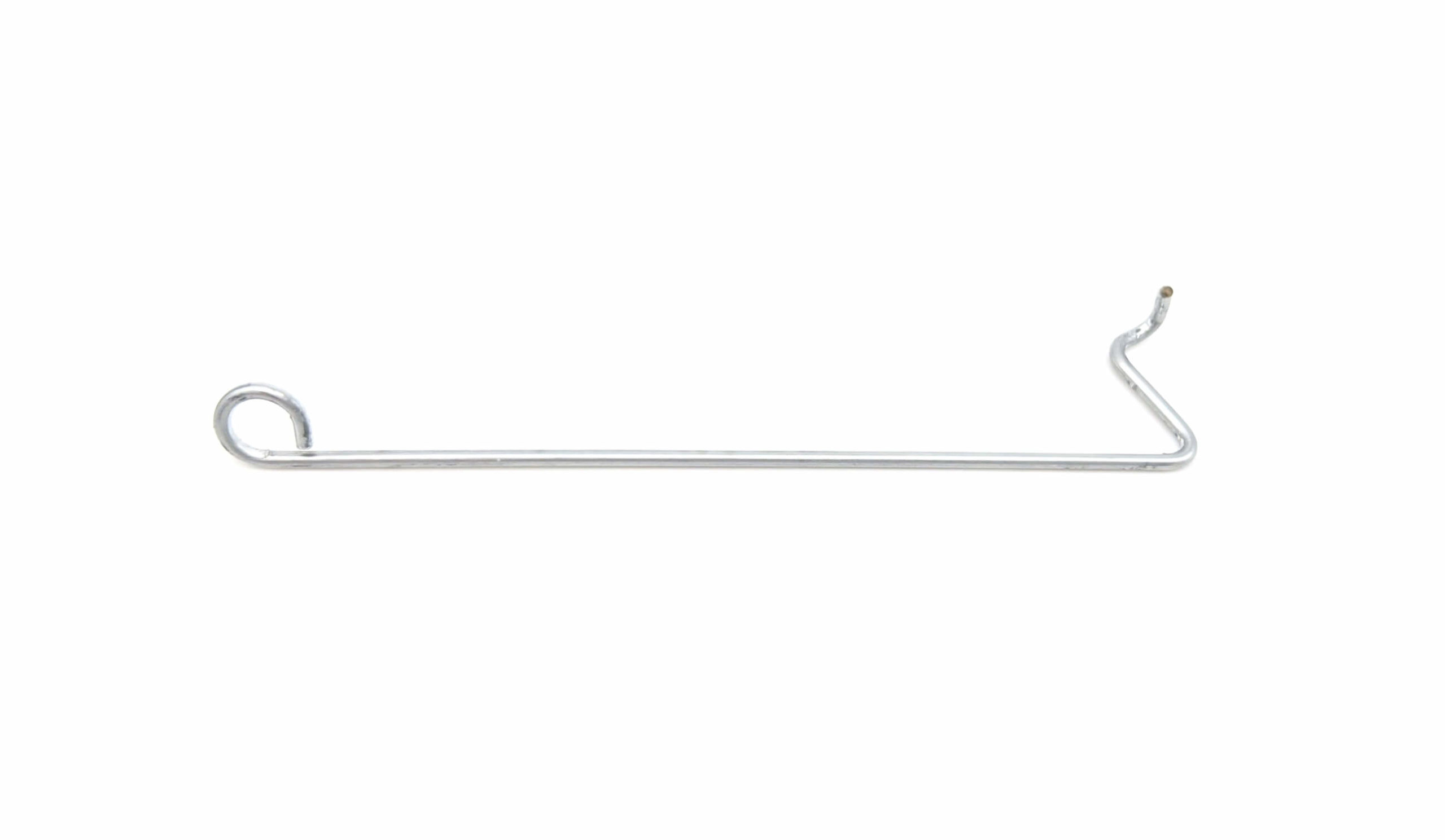

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the realm of engineering, springs play a vital role, acting as essential components in countless devices. From the delicate hairspring in a watch to the robust coil springs in

In the realm of engineering, springs play a vital role, acting as essential components in countless devices. From the delicate hairspring in a watch to the robust coil springs in a car suspension, these elastic marvels provide the ability to store and release energy, ensuring smooth operation and resilience. While traditional spring materials like steel have long dominated this field, a new contender has emerged – plastic wave springs. Offering a unique combination of flexibility, durability, and cost-effectiveness, plastic wave springs are poised to revolutionize spring applications across various industries. In this article, we will delve into the exciting world of plastic wave springs, exploring their construction, advantages, and the diverse applications where they are making their mark.

Unlike their coiled counterparts, plastic wave springs are crafted from thin strips of high-performance polymers, carefully molded into a series of waves. These waves, when compressed, store energy and provide a predictable force, similar to traditional springs. The beauty of this design lies in its ability to pack a lot of spring force into a small space. This makes them ideal for applications where space is limited or where weight reduction is crucial.

The advent of plastic wave springs has brought about a paradigm shift in the world of springs. These innovative components offer a compelling set of advantages over traditional metal springs, including:

The versatility of plastic wave springs has opened up a world of possibilities across numerous industries. Here are some notable applications:

Despite their many advantages, plastic wave springs do have some limitations. While advancements in polymer science continue to expand the capabilities of plastic wave springs, challenges remain in areas such as:

Looking ahead, research and development efforts are focused on addressing these challenges, further expanding the capabilities of plastic wave springs. Advancements in polymer technology, coupled with innovative design techniques, are poised to make plastic wave springs even more versatile and adaptable, opening up new horizons for their applications. With their unique combination of advantages, plastic wave springs are undeniably a force to be reckoned with in the world of spring technology. Their potential to revolutionize spring applications across diverse industries is evident, and their future is bright.

Plastic wave springs have proven to be a valuable addition to the world of spring technology. They offer a compelling blend of flexibility, durability, and cost-effectiveness, making them suitable for a wide range of applications. As research and development in polymer science continue to advance, the capabilities of plastic wave springs are poised to grow even further. The future of plastic wave springs is exciting, and their presence is sure to leave an indelible mark on the engineering landscape.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.