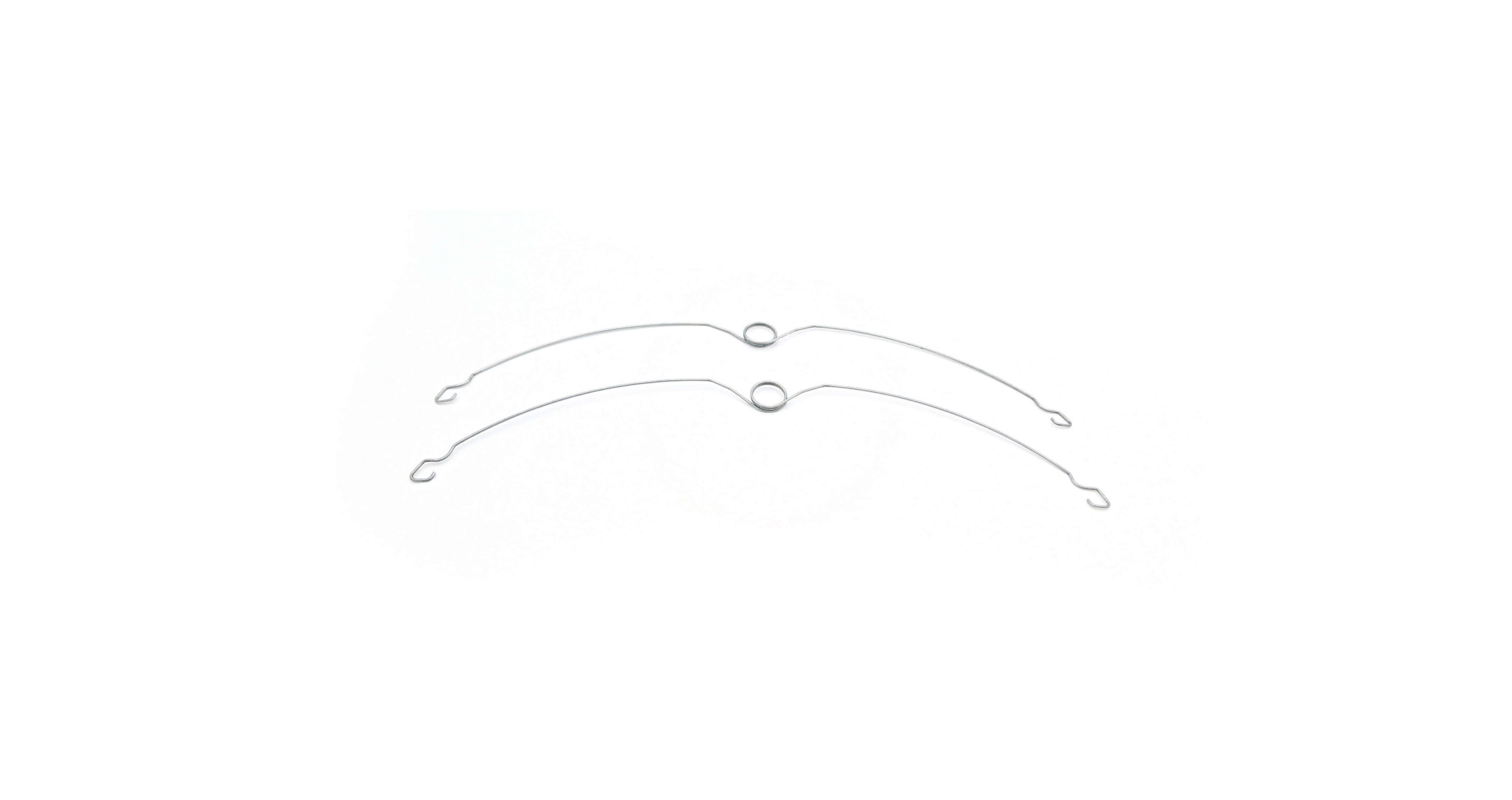

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Have you ever wondered how a tape measure retracts smoothly and effortlessly? Or how a retractable pen manages to stay tucked away until you need it? The answer lies in

Have you ever wondered how a tape measure retracts smoothly and effortlessly? Or how a retractable pen manages to stay tucked away until you need it? The answer lies in a seemingly simple yet ingenious invention: the negator spring. This unassuming spring, often hidden from view, is the unsung hero behind countless retractable tools, ensuring their smooth operation and consistent performance. In this article, we will delve into the fascinating world of negator springs, exploring their design, function, and the many applications that rely on their unique properties.

A negator spring, also known as a constant-force spring, is a thin, coiled metal band with a slightly concave cross-section. This unique design sets it apart from traditional coil springs, enabling it to exert a consistent force throughout its entire extension and retraction cycle. When coiled, the negator spring adopts a flat cross-section, but as it unrolls, it returns to its original curved shape. This constant force is generated due to the inherent elastic properties of the metal, which constantly tries to return to its original shape.

Imagine a flat piece of metal bent into a gentle arc. When you try to straighten it, it resists the force and tries to return to its curved shape. This is precisely how a negator spring works. As it unrolls, the spring's inherent curvature is constantly trying to pull it back into a coiled state, resulting in a consistent force throughout the entire extension. This consistent force is what makes it ideal for retractable applications.

Negator springs offer several distinct advantages over traditional coil springs, making them the preferred choice for various applications:

Negator springs are found in a wide array of applications, quietly working behind the scenes to ensure smooth and reliable operation. Here are some common examples:

While primarily known for their role in retractable applications, negator springs have proven their versatility in other areas as well. Their ability to provide consistent force makes them ideal for:

Designing and manufacturing negator springs involves careful consideration of several factors:

Negator springs, though often hidden from view, play a vital role in countless applications, ensuring smooth operation and reliable performance. Their ability to provide consistent force, compact design, and durability make them an essential component in modern retractable tools, medical devices, and various other technologies. As technology continues to evolve, negator springs are likely to find even more innovative applications, continuing to serve as the unsung heroes of our everyday lives.

Next time you encounter a retractable tool or a device with smooth, consistent retraction, remember the negator spring silently working behind the scenes. This unassuming spring, through its clever design and consistent force, continues to revolutionize the way we interact with technology, making our lives easier and more efficient.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.