Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Multi wave springs are a relatively new type of spring design that offers a number of advantages over traditional coil springs. These springs are characterized by their unique wave-like shape,

Multi wave springs are a relatively new type of spring design that offers a number of advantages over traditional coil springs. These springs are characterized by their unique wave-like shape, which provides them with increased load capacity, a longer service life, and superior vibration damping capabilities. This article will delve into the intricacies of multi wave springs, exploring their design, advantages, applications, and the potential they hold for various industries.

Multi wave springs, often referred to as wave springs or wave washers, are a fascinating advancement in spring technology. Unlike traditional coil springs, which rely on helical coils to store and release energy, multi wave springs utilize a series of interconnected waves to achieve their desired spring action. These waves are typically formed from a single piece of metal, carefully engineered to provide precise spring characteristics.

The design of a multi wave spring is intricate, consisting of a series of alternating waves that interlock and create a compact spring configuration. This wave pattern is not just a visually appealing feature; it is the foundation of their exceptional performance. The interlocking waves enable the spring to distribute loads more evenly across its surface, resulting in a greater load capacity compared to conventional coil springs.

The unique design of multi wave springs translates into a range of benefits that make them a compelling alternative in many applications. Some of the key advantages include:

**1. Higher Load Capacity:** Due to their wave-like structure, multi wave springs can handle significantly higher loads compared to coil springs of similar dimensions. This increased load capacity makes them ideal for applications where space is limited, but high force is required.

**2. Longer Service Life:** The even distribution of load and the reduced stress concentration points within the spring's design contribute to a longer service life. Multi wave springs are known for their resistance to fatigue and wear, allowing them to withstand repeated compression and extension cycles without compromising their functionality.

**3. Superior Vibration Damping:** The wave-like structure of these springs provides exceptional vibration damping capabilities. The waves effectively dissipate energy, reducing noise and vibrations in various applications. This attribute is particularly valuable in machinery, automotive components, and aerospace systems.

**4. Compact Design:** Multi wave springs can be designed to fit into tight spaces, offering a more compact solution compared to coil springs. This makes them ideal for applications where space is at a premium, such as in electronics, medical devices, and other miniaturized systems.

**5. High Resilience:** These springs exhibit excellent resilience, meaning they can withstand repeated compression and extension cycles without losing their shape or losing their spring characteristics.

The diverse benefits of multi wave springs have led to their widespread adoption across various industries. Here are some notable applications:

**1. Automotive Industry:** Multi wave springs are frequently employed in automotive suspension systems, shock absorbers, and engine mounts. Their superior vibration damping and load capacity contribute to a smoother ride and reduced noise levels.

**2. Aerospace Industry:** In aerospace, multi wave springs play a crucial role in landing gear systems, actuators, and other critical components. Their high resilience and fatigue resistance make them essential for ensuring safety and reliability.

**3. Electronics and Appliances:** The compact design and excellent spring characteristics of multi wave springs make them ideal for use in electronics, such as switches, connectors, and actuators. They also find applications in appliances, ensuring the smooth operation of various components.

**4. Medical Devices:** Multi wave springs are used in a variety of medical devices, including surgical instruments, prosthetics, and medical implants. Their biocompatibility and superior performance make them suitable for these sensitive applications.

**5. Industrial Machinery:** These springs are also used in industrial machinery, including pumps, compressors, and other equipment that requires high load capacity and vibration damping capabilities.

While multi wave springs offer significant advantages, there are certain challenges associated with their design and manufacturing. The complex geometry of the waves requires advanced manufacturing processes and precise control over material properties. However, advancements in manufacturing techniques, such as laser cutting and forming, are constantly improving the production efficiency and quality of these springs.

The future of multi wave springs looks promising. Ongoing research and development efforts are focusing on exploring new materials and design optimization techniques. This will lead to even more innovative applications and further enhance their performance. For example, the use of composite materials could lead to lighter weight springs with greater load capacity, opening up possibilities for weight-sensitive applications.

Multi wave springs represent a significant advancement in spring technology, offering a unique combination of load capacity, durability, vibration damping, and compactness. Their widespread adoption across various industries reflects their versatility and ability to meet challenging engineering requirements. As research and development continue, we can expect to see even more innovative applications of multi wave springs, further shaping the future of mechanical design and engineering.

Multi wave springs are a testament to the continuous evolution of spring technology. Their unique design and exceptional performance capabilities have revolutionized various industries, offering a compelling alternative to traditional coil springs. As we move forward, these springs will undoubtedly play an increasingly vital role in shaping the future of mechanical design and engineering, paving the way for more efficient, reliable, and innovative solutions across a wide range of applications.

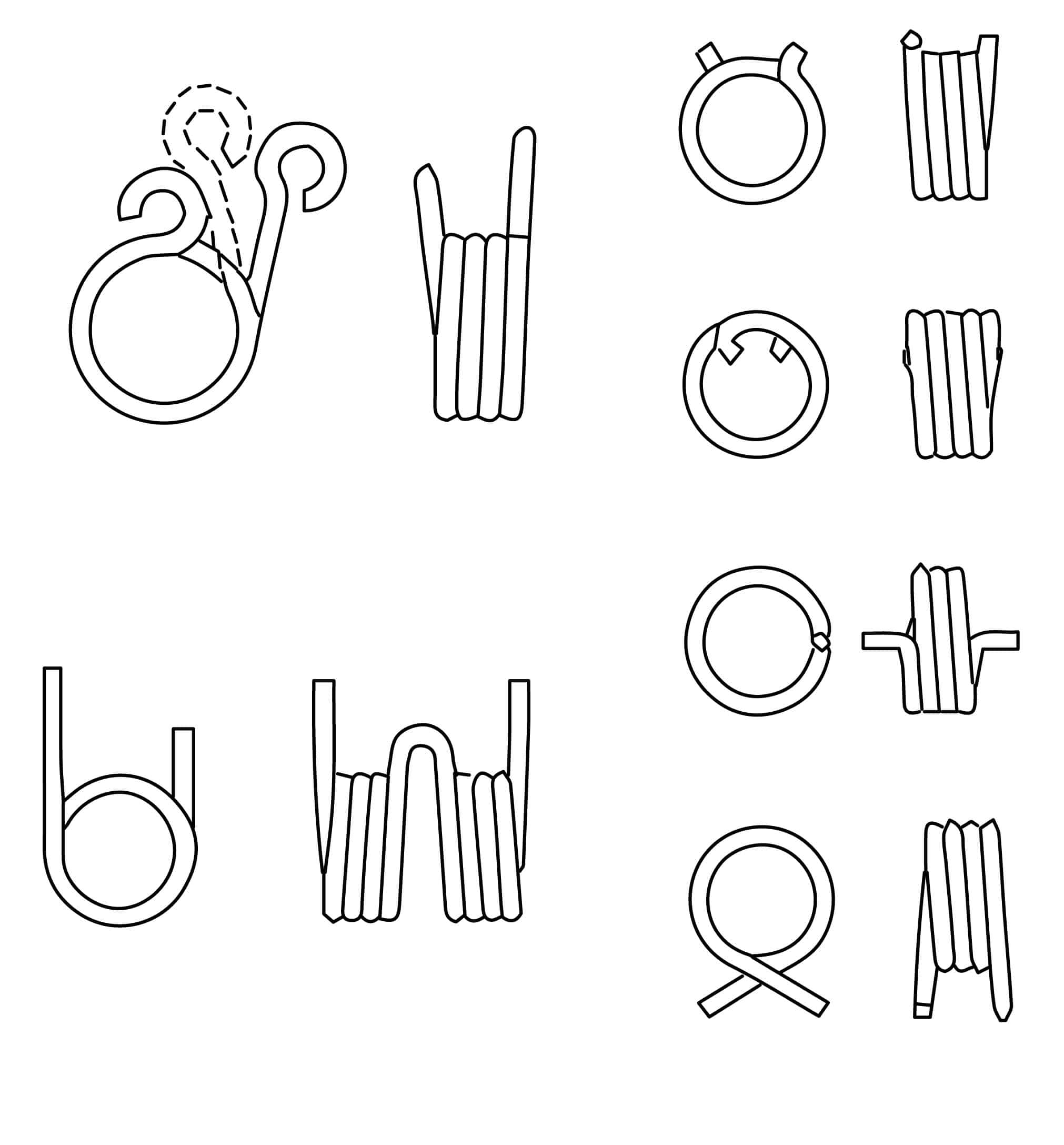

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.