Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

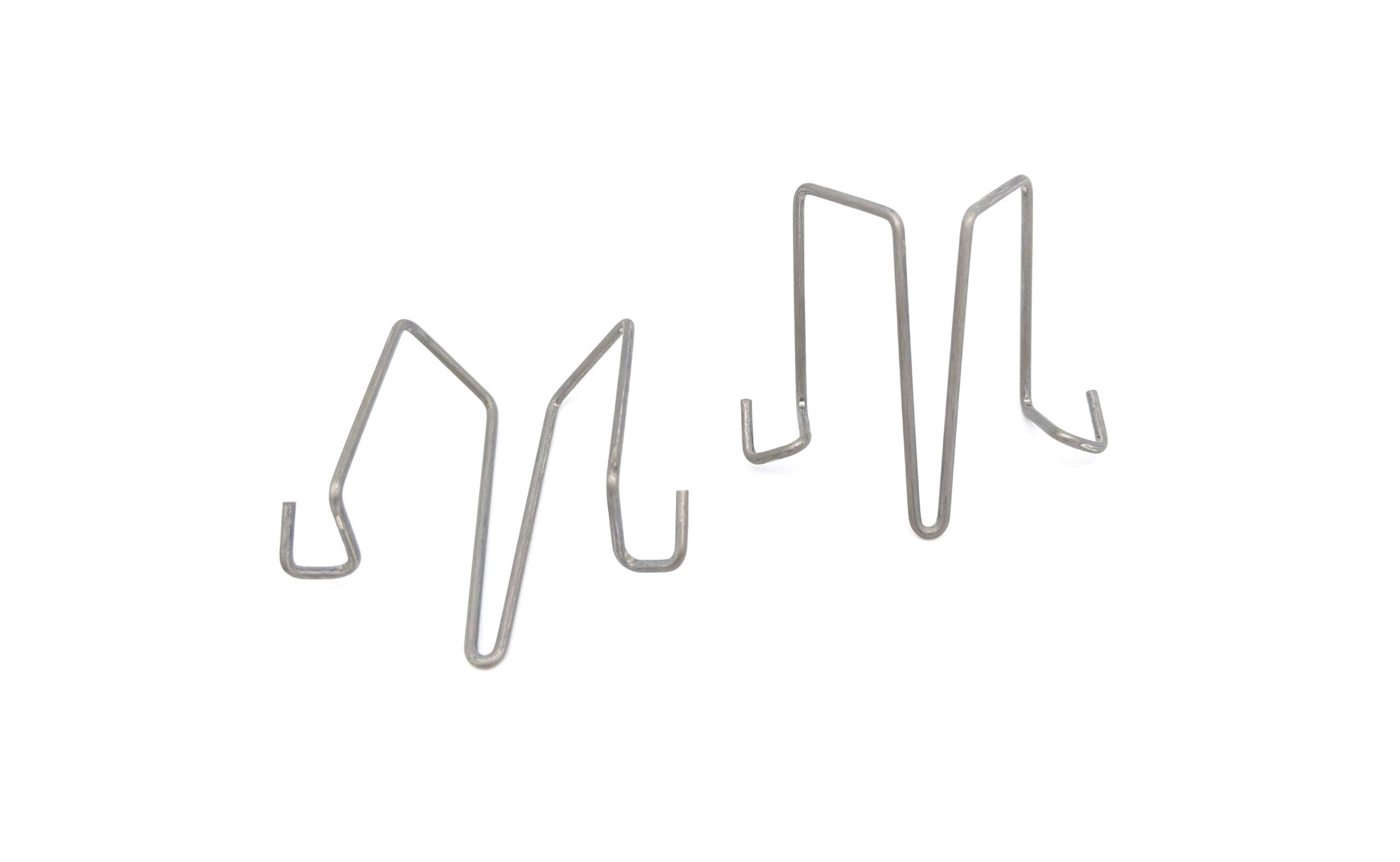

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous coils of metal, are essential components in countless mechanical systems. From the delicate balance spring in a wristwatch to the robust suspension springs in a car, springs

Springs, those ubiquitous coils of metal, are essential components in countless mechanical systems. From the delicate balance spring in a wristwatch to the robust suspension springs in a car, springs store and release energy, absorb shocks, and provide constant force. But how much can a spring be compressed before it reaches its limit? Understanding maximum compression is crucial for engineers and designers to ensure the safe and reliable operation of any system that utilizes springs.

At the heart of spring behavior lies Hooke's Law, a fundamental principle of elasticity. It states that the force exerted by a spring is directly proportional to its deformation. This means that the more you compress or stretch a spring, the greater the force it will resist with. However, Hooke's Law only holds true within a specific range of deformation, known as the elastic limit.

Beyond the elastic limit, the spring's material experiences permanent deformation. This means that even if the force is removed, the spring will not return to its original shape. In extreme cases, the spring can even fail completely, breaking or yielding under excessive stress.

Several factors influence the maximum compression a spring can withstand before reaching its limit. These include:

1. Spring Material: The material of the spring is paramount. Some materials, like spring steel, are renowned for their elasticity and high yield strength. Others, such as softer metals, may deform more easily under compression. The choice of material is crucial for determining a spring's maximum compression capacity.

2. Spring Design: The design of the spring, including its coil diameter, wire diameter, and number of coils, significantly impacts its compression limits. A spring with a smaller coil diameter and thicker wire will generally withstand more compression than a spring with a larger coil diameter and thinner wire.

3. Operating Environment: External factors, such as temperature and humidity, can also affect a spring's performance. Extreme temperatures can affect a spring's elasticity, while moisture can lead to corrosion, weakening the material and reducing its compression capacity.

4. Load Application: The manner in which the load is applied to the spring is also crucial. A sudden, shock-like load can significantly exceed the spring's elastic limit, even if the load itself is relatively small. Conversely, a gradual, controlled application of load can allow a spring to compress further without permanent deformation.

Determining the maximum compression of a spring is essential for any application where the spring is expected to handle significant loads. Engineers and designers typically use several methods to assess a spring's compression limits:

1. Material Properties: By consulting the material properties of the spring, such as its yield strength and elastic modulus, engineers can estimate the maximum stress the spring can withstand before yielding.

2. Spring Design Calculations: Using established formulas and software tools, engineers can calculate the maximum compression based on the spring's geometry and material properties. This provides a theoretical estimate of the spring's performance.

3. Experimental Testing: In many cases, actual testing is conducted to determine the maximum compression of a spring. This involves subjecting the spring to increasing loads until it reaches its yield point or failure point. The results of these tests are invaluable for validating theoretical calculations and providing real-world data.

Exceeding the maximum compression of a spring can have serious consequences. It can lead to:

1. Permanent Deformation: As mentioned earlier, exceeding the elastic limit results in permanent deformation of the spring. This can compromise the spring's performance and reduce its ability to return to its original shape.

2. Fatigue Failure: Repeatedly exceeding the spring's maximum compression can lead to fatigue failure. Over time, the repeated stress cycles can weaken the spring material and eventually cause it to fracture.

3. System Malfunction: In many systems, the proper function relies on the spring's ability to compress and return to its original shape. Exceeding the spring's compression limit can disrupt the system's operation, leading to unpredictable behavior and potential safety hazards.

To ensure the safe and reliable operation of spring-based systems, it is crucial to operate within the spring's specified compression limits. This can be achieved by:

1. Selecting the Right Spring: Choosing a spring with a suitable material and design for the intended application is paramount. Consulting with spring manufacturers or experienced engineers can help select the right spring for the job.

2. Careful Load Management: It is essential to design systems to avoid sudden or excessive loads on springs. Incorporating shock absorbers or other load-dampening mechanisms can help mitigate the effects of shock loads.

3. Regular Inspection and Maintenance: Regular inspection and maintenance of springs are crucial for detecting any signs of wear or damage. Replacing damaged or worn-out springs promptly can prevent catastrophic failures.

Springs, with their ability to store and release energy, are essential components in numerous mechanical systems. Understanding the maximum compression of a spring is crucial for ensuring its safe and reliable operation. By carefully considering the factors that affect maximum compression, selecting the right spring, and implementing proper load management and maintenance practices, engineers and designers can harness the power of elasticity to create innovative and dependable solutions for countless applications.

In conclusion, understanding the maximum compression of a spring is crucial for ensuring the safe and reliable operation of any system that utilizes springs. By carefully considering the factors that affect maximum compression, selecting the right spring, and implementing proper load management and maintenance practices, engineers and designers can harness the power of elasticity to create innovative and dependable solutions for countless applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.