Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are ubiquitous in our world, from the tiny coils in our watches to the massive suspension systems in vehicles. Their ability to store and release energy, providing a resilient

Springs are ubiquitous in our world, from the tiny coils in our watches to the massive suspension systems in vehicles. Their ability to store and release energy, providing a resilient push or pull, makes them indispensable in countless applications. But how much can you compress a spring before it reaches its limit? Understanding the maximum compression of a spring is crucial for engineers, designers, and anyone seeking to optimize spring performance and ensure safety in their applications.

The maximum compression of a spring, also known as its 'solid height,' refers to the point at which the coils of the spring are tightly packed together, leaving no further space for compression. At this point, the spring's elastic properties are fully exhausted, and any further applied force can cause permanent deformation or even failure.

A spring's maximum compression is not a fixed value; it depends on various factors, including:

The material of the spring plays a crucial role in determining its maximum compression. Spring steel, a common material, exhibits high elasticity and can withstand significant compression before yielding. However, softer materials like phosphor bronze will have lower maximum compression limits.

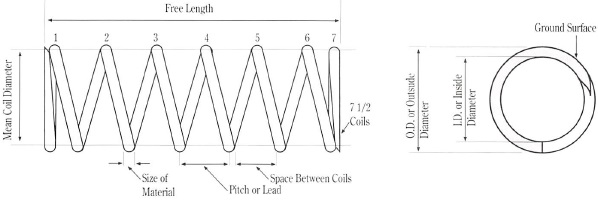

The design features of a spring, such as the wire diameter, coil diameter, and number of coils, greatly influence its compression capacity. A spring with a thicker wire and a larger coil diameter will generally have a higher maximum compression than a spring with a thinner wire and smaller coil diameter.

The applied load on the spring is directly proportional to its compression. The greater the load, the more the spring will compress. Exceeding the maximum load capacity of the spring will lead to its permanent deformation or failure.

The type of spring end, whether it's closed, ground, or squared, can affect its maximum compression. Closed ends can sometimes lead to slightly lower maximum compression due to the added contact point.

Temperature fluctuations can affect the material properties of the spring. High temperatures can reduce the spring's elasticity, leading to a decrease in maximum compression.

Pushing a spring beyond its maximum compression limit can have serious consequences:

When a spring is compressed beyond its elastic limit, it undergoes permanent deformation. The coils will not return to their original position after the load is removed, making the spring unusable for its intended purpose.

In extreme cases, excessive compression can lead to spring failure. This can manifest as a sudden break in the wire, a collapse of the coils, or a complete loss of the spring's function.

Spring failure can create safety hazards in various applications. A broken spring in a machine can lead to malfunction, while a failed spring in a vehicle suspension system can compromise its stability.

To determine the maximum compression of a spring, you can rely on several methods:

The most reliable way to find the maximum compression is to consult the manufacturer's specifications for the particular spring you are using. They will typically provide the 'solid height' or 'maximum compression' value.

Engineers can calculate the maximum compression using various formulas and models. These calculations often consider the spring material, design parameters, and load conditions.

For critical applications, experimental testing can be conducted to determine the maximum compression of a spring. This involves applying increasing loads to the spring and measuring its compression until it reaches its limit.

To ensure optimal spring performance and avoid exceeding its maximum compression, consider the following tips:

Select a spring material that aligns with the load requirements and operating environment.

Ensure that the spring's design provides ample capacity to handle the intended loads and prevent overcompression.

Factor in the potential temperature variations during operation and choose a spring material that can withstand them.

Incorporate safety factors in your design to account for uncertainties and potential overloading. This helps ensure that the spring remains within its operational limits.

Understanding the maximum compression of a spring is essential for any application where spring performance is critical. By considering the factors that influence compression, being aware of the consequences of exceeding the limits, and following best practices for optimization, you can ensure the reliable and safe operation of your spring-based systems.

Remember, springs are reliable components, but they have their limitations. By understanding the concept of maximum compression and taking precautions to avoid exceeding it, you can ensure the long-term performance and safety of your applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.