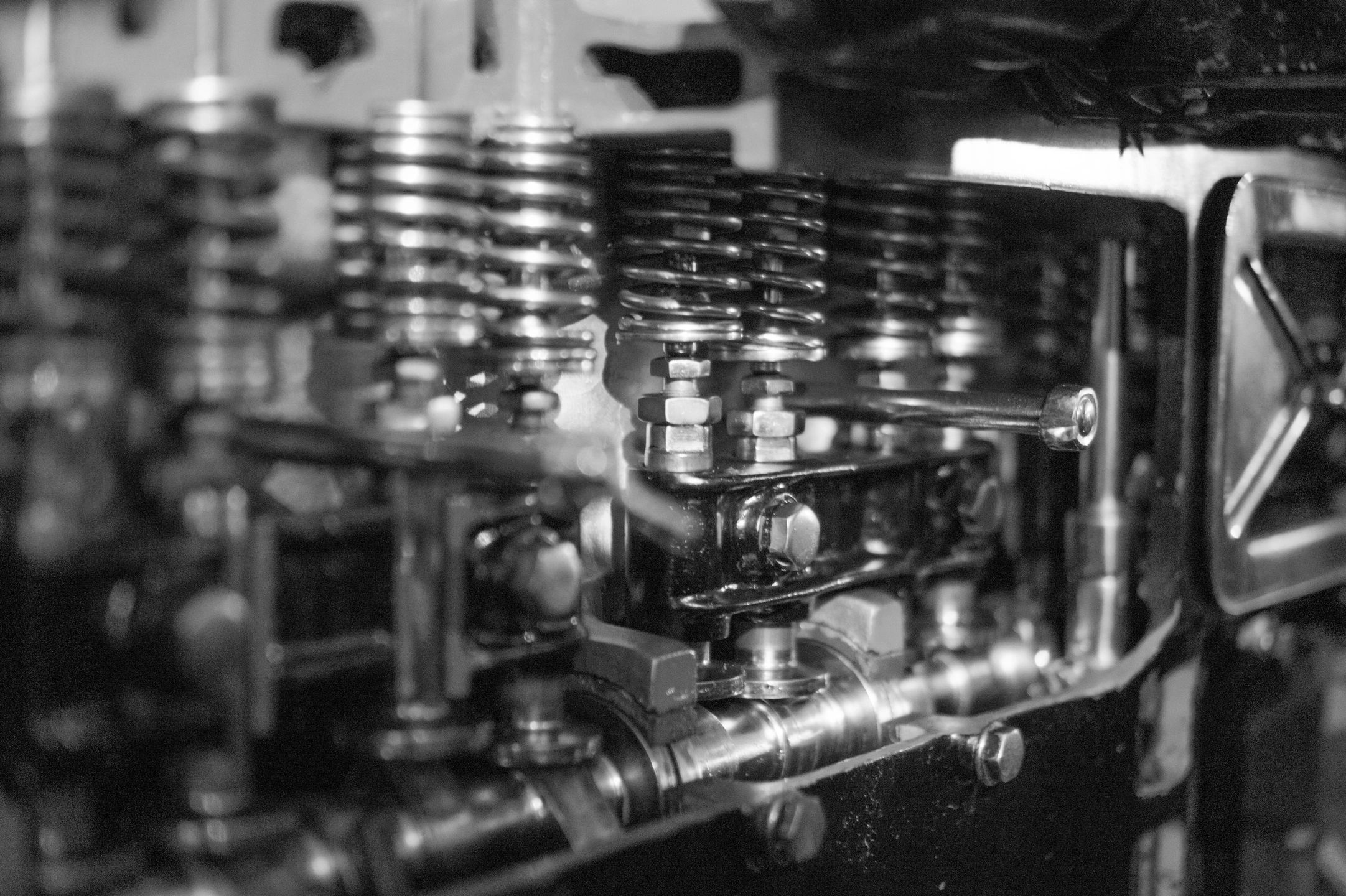

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are ubiquitous in mechanical systems, serving as essential components in everything from car suspensions to door hinges. Understanding how to maximize spring compression is critical for ensuring optimal performance,

Springs are ubiquitous in mechanical systems, serving as essential components in everything from car suspensions to door hinges. Understanding how to maximize spring compression is critical for ensuring optimal performance, efficiency, and safety. This comprehensive guide will delve into the fundamental principles behind spring compression, explore the factors that influence maximum compression, and provide practical strategies for achieving optimal results.

At its core, spring compression is governed by Hooke's Law, a fundamental principle in physics. This law states that the force required to compress a spring is directly proportional to the amount of compression. In simpler terms, the more you compress a spring, the more force it will exert to return to its original length. This relationship can be expressed mathematically as:

F = -kx

Where:

The spring constant (k) is a crucial property that determines the stiffness of the spring. A higher spring constant means a stiffer spring, requiring more force for a given amount of compression. Conversely, a lower spring constant indicates a softer spring, requiring less force to achieve the same compression.

The maximum compression a spring can withstand before permanently deforming or breaking is influenced by several factors. Let's break these down:

Here are some practical strategies to optimize spring compression for your specific application:

Maximizing spring compression is a critical aspect of design and engineering, ensuring optimal performance and longevity of your mechanical systems. By understanding the fundamental principles of spring compression, considering the factors that influence maximum compression, and employing the strategies outlined in this guide, you can effectively optimize spring performance in your applications. Remember that a properly chosen and implemented spring is a key to achieving efficiency, reliability, and safety in your mechanical designs.

By understanding the physics behind spring compression, considering the influencing factors, and implementing strategic approaches, you can effectively maximize spring compression while maintaining safety and efficiency in your mechanical systems. This knowledge will empower you to optimize performance, enhance durability, and ensure the reliable operation of your spring-driven mechanisms.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.