Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous coiled wonders, are integral to countless mechanisms and devices. Their ability to store and release energy is unmatched, making them essential for everything from car suspensions to

Springs, those ubiquitous coiled wonders, are integral to countless mechanisms and devices. Their ability to store and release energy is unmatched, making them essential for everything from car suspensions to door hinges. But have you ever wondered about the maximum compression a spring can withstand? What factors influence this limit? This article delves into the fascinating world of spring compression, exploring the factors that determine how much we can squeeze these resilient coils before they reach their breaking point.

Springs are essentially elastic devices that store potential energy when compressed or stretched. This ability stems from their inherent material properties and their carefully engineered design. The maximum compression a spring can handle depends on a fascinating interplay of factors, including the material used, the spring's geometry, and the applied force.

Imagine a spring as a coiled wire. When you push on one end, it compresses, storing energy. The more you compress it, the more energy it stores. But this storage capacity has limits. Eventually, you'll reach a point where pushing further will cause the spring to deform permanently, or even break.

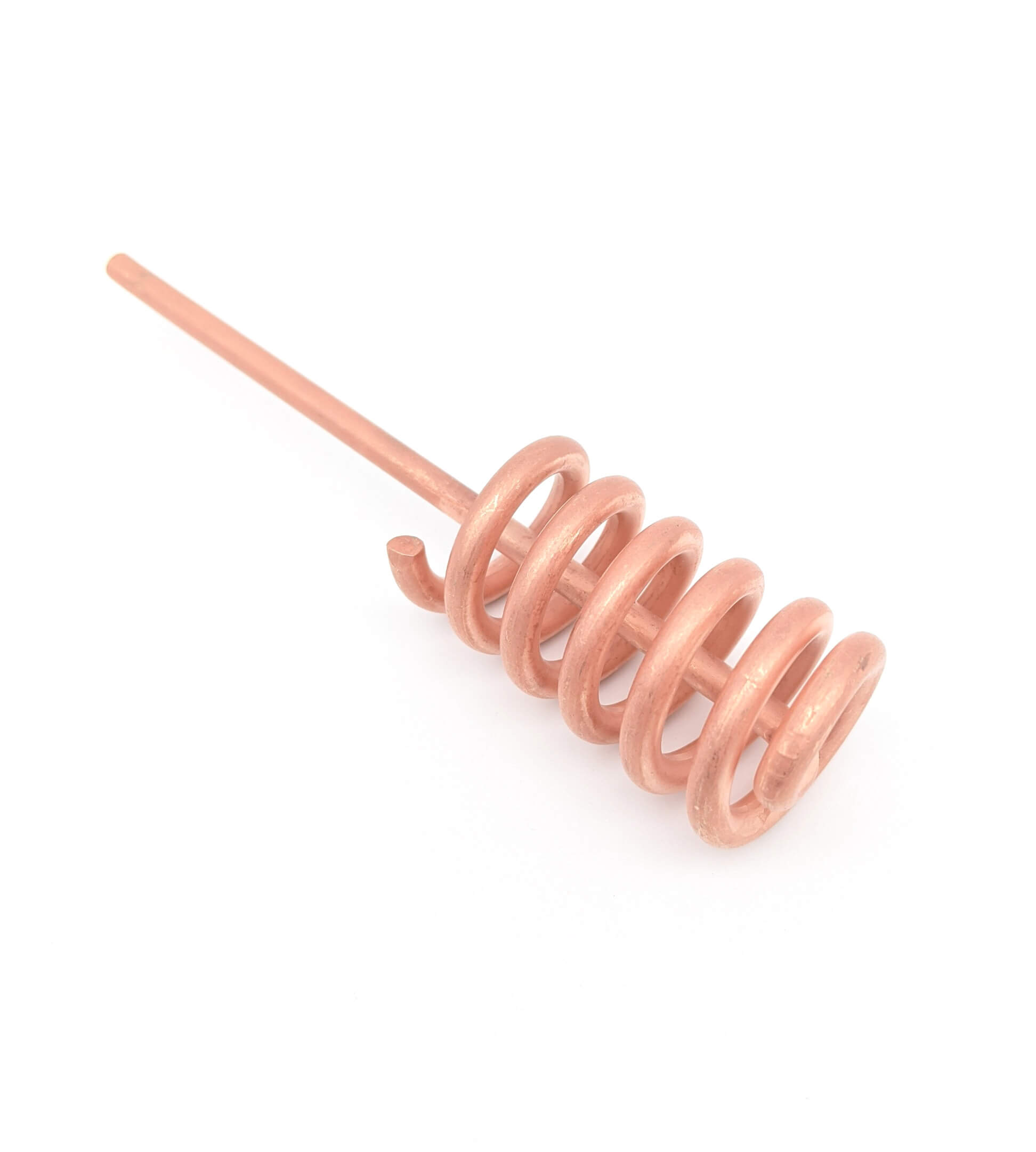

The material a spring is made of plays a crucial role in its ability to compress. Steel springs, for instance, are known for their high strength and resilience. They can withstand significant compression before yielding or breaking. On the other hand, springs made of softer materials like copper or brass will deform more easily under compression. This difference in material behavior is directly related to the material's elastic modulus. The higher the elastic modulus, the stiffer the material, and the more compression it can withstand before yielding.

The shape of a spring, including its diameter, wire thickness, and number of coils, significantly influences its compression limits. Springs with a larger diameter or thicker wire can withstand more compression than those with smaller diameters or thinner wires. This is because the larger cross-sectional area provides more material to resist the applied forces. The number of coils in a spring also plays a role. More coils mean a longer spring, allowing for greater compression before reaching the limit. This makes sense, as the compression is distributed over a greater length, reducing the stress on each individual coil.

The force applied to a spring is the driving factor behind compression. The greater the force, the more the spring compresses. However, this relationship isn't linear. The compression of a spring tends to increase more slowly as the applied force increases. This is due to the spring's elasticity - as it compresses, it becomes stiffer, resisting further compression. This means that the spring's maximum compression is often determined by the force it can withstand before yielding or breaking.

The yield point of a spring is a critical parameter. It represents the maximum force a spring can withstand before it starts to deform permanently. Beyond this point, the spring will no longer return to its original shape after the load is removed. The yield point is an important factor in determining the maximum compression a spring can handle. It's essential to consider this limit when designing springs for specific applications. If a spring is repeatedly compressed beyond its yield point, it will gradually lose its ability to store and release energy efficiently, eventually leading to failure.

When designing a spring, engineers carefully consider the material, geometry, and anticipated load to determine the maximum compression it can withstand. They use a combination of theoretical calculations and experimental testing to ensure the spring can handle the intended load safely. The goal is to balance the spring's strength with its flexibility, ensuring it performs its intended function while remaining durable and reliable. A key aspect of spring design is ensuring adequate safety margins. This means designing the spring to withstand forces significantly higher than those expected during normal operation, providing a buffer against unforeseen circumstances. This ensures the spring remains functional and reliable even when subjected to occasional overloads.

Springs are found in countless applications, ranging from simple door hinges to complex automotive suspensions. Their ability to store and release energy makes them essential for everything from shock absorption to providing mechanical force. Here are a few examples of how spring compression plays a crucial role in everyday life:

The maximum compression a spring can handle is a critical factor in its design and application. Understanding the interplay of material properties, geometry, and applied force is essential for ensuring reliable and safe performance. By carefully considering these factors, engineers can design springs that meet specific requirements while maximizing their potential for compression. From simple door hinges to complex automotive suspensions, springs continue to play a vital role in countless aspects of our modern world.

As we delve deeper into the fascinating world of springs, we discover that their ability to compress is not limitless. It's a carefully balanced interplay of material properties, geometry, and applied forces. Understanding these limitations allows us to design springs that can withstand the demands of various applications while maximizing their potential for compression, ensuring their continued role in shaping our technological landscape.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.