Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Coil spring compressors are indispensable tools for anyone working on automotive suspension systems. They allow for the safe and efficient compression of coil springs, making it possible to remove and

Coil spring compressors are indispensable tools for anyone working on automotive suspension systems. They allow for the safe and efficient compression of coil springs, making it possible to remove and install components like struts, shocks, and control arms. This comprehensive guide will delve into the intricacies of using a coil spring compressor, covering everything from choosing the right type to ensuring safe and successful operation. We'll explore the different types of compressors, their advantages and disadvantages, and provide step-by-step instructions on how to use them effectively. Whether you're a seasoned mechanic or a DIY enthusiast, this guide will equip you with the knowledge and confidence to tackle coil spring compression tasks with ease.

Coil spring compressors are mechanical devices designed to safely compress and hold coil springs in place while you work on your vehicle's suspension. They are essential for tasks such as replacing struts, shocks, or control arms, as they allow you to remove the spring without having it suddenly release and potentially cause injury or damage.

There are various types of coil spring compressors available, each with its own unique design and advantages. Let's explore some of the most common types:

External coil spring compressors are the most common type and are often found in home garages. They work by applying pressure to the outside of the spring, using two arms that clamp onto the coil. They are generally easy to use, relatively inexpensive, and are suitable for most standard spring compression tasks. One potential drawback is that they may not be suitable for all spring designs, especially those with closely spaced coils or unusual configurations.

Internal coil spring compressors, as the name suggests, work by applying pressure from the inside of the spring. They typically use a set of threaded rods or a hydraulic cylinder that pushes against the spring from within. These compressors offer a more secure grip and can be used on a wider range of spring designs, including those with close-spaced coils. However, they can be more difficult to use, especially in confined spaces, and often require specialized tools.

Hydraulic coil spring compressors are typically used in professional workshops. They offer the advantage of precise control over the compression force. A hydraulic pump is used to pressurize a cylinder, which then pushes against the spring. Hydraulic compressors can handle heavy-duty springs and offer a more controlled and stable compression process, but they are also generally more expensive and bulky than other types.

Selecting the right coil spring compressor depends on the specific application and the type of vehicle you're working on. Consider the following factors:

Using a coil spring compressor requires a degree of caution and adherence to safety guidelines. Here's a step-by-step guide for safe and successful operation:

Before starting, gather all the necessary tools, including:

Park the vehicle on a level surface and engage the parking brake. Remove the wheel(s) corresponding to the spring you'll be compressing. Place wheel chocks behind the remaining wheels to prevent movement.

Use a jack to lift the vehicle to a height that allows you to comfortably work on the suspension. Securely position jack stands under the frame to support the vehicle.

If the spring is already under tension, you'll need to release it before you can begin compressing. This can be done by loosening the strut or shock mounting bolts, allowing the spring to extend slightly.

Refer to the manufacturer's instructions for the specific type of coil spring compressor you're using. Typically, you'll need to position the compressor's arms or clamps around the coil, ensuring a secure grip. The compression arms should be positioned securely and tightly against the coils. If using a hydraulic type, you may need to use a hydraulic pump to pressurize the cylinder.

Start compressing the spring slowly and observe the spring's behavior. You should hear a slight “creaking” or “groaning” sound as the spring compresses, but it should never sound or feel like it is in danger of breaking. Avoid applying excessive force or compressing the spring too quickly.

Once the spring is compressed sufficiently, you can remove the components (strut, shock, control arm) that were connected to the spring.

With the new components installed, carefully release the compression on the spring. When you release the spring, do so in a controlled manner to avoid a sudden release of energy. The spring will try to extend rapidly. Be very cautious as it will have a great deal of stored energy.

Ensure all fasteners are tightened to the manufacturer's specifications using a torque wrench. Avoid overtightening, as this can damage the components.

Carefully lower the vehicle and remove the jack stands. Ensure the wheel is tightened to the correct specification, and go for a test drive to check for any unusual sounds or handling issues.

When working with coil spring compressors, safety should be paramount. Here are some crucial precautions to follow:

Here are some additional tips to enhance your coil spring compression experience:

Coil spring compressors are essential tools for safely and efficiently working on automotive suspension systems. By understanding the different types of compressors, choosing the right one for your needs, and following safety guidelines, you can tackle coil spring compression tasks with confidence. Remember that safety is paramount, and always consult with a qualified mechanic if you have any doubts or concerns.

With this comprehensive guide in hand, you are now equipped with the knowledge and confidence to master the use of a coil spring compressor. Remember, safety is paramount. By following the provided tips and guidelines, you can effectively and safely compress and release coil springs, facilitating your automotive repair and maintenance projects. Happy wrenching!

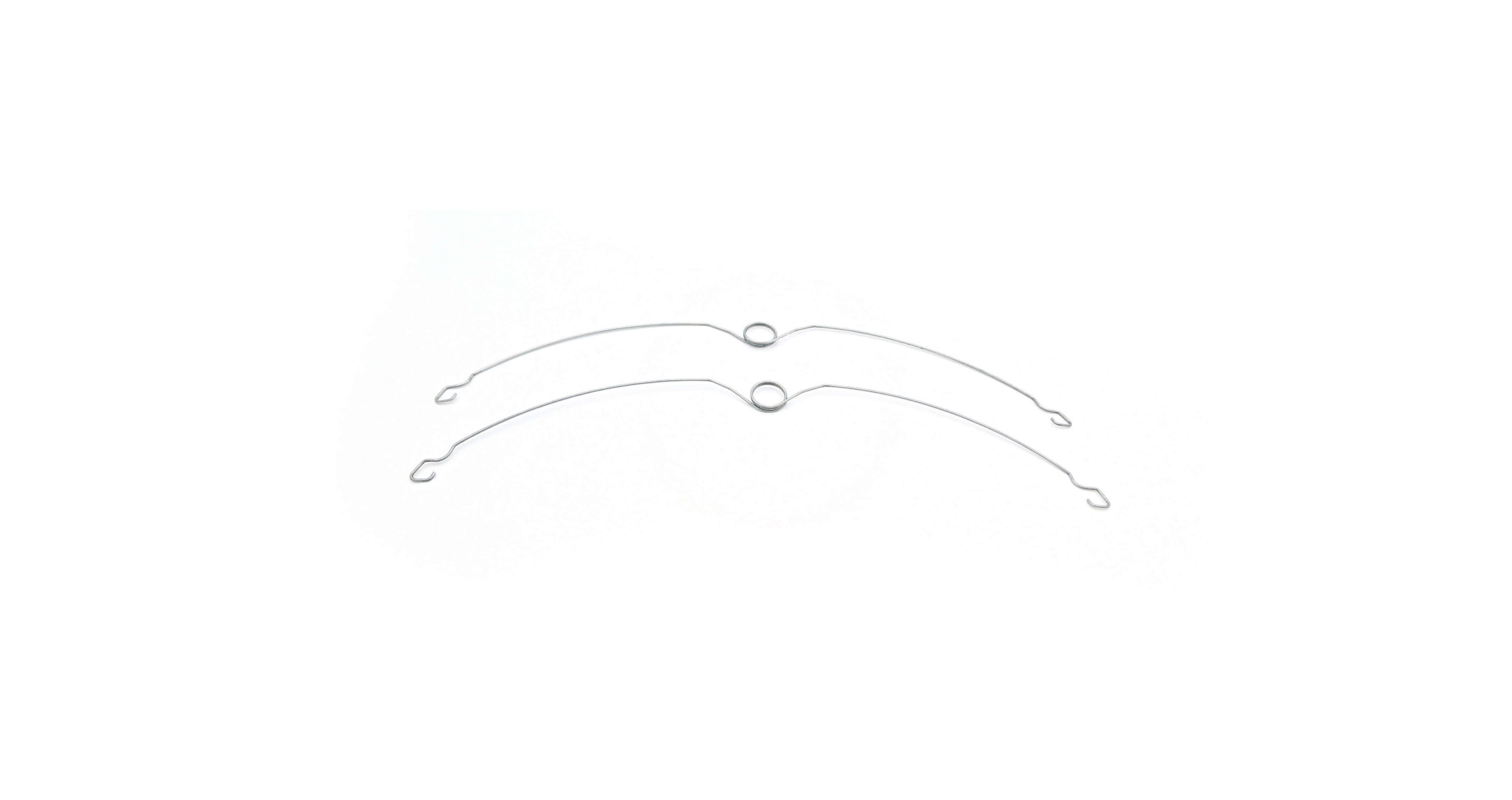

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.