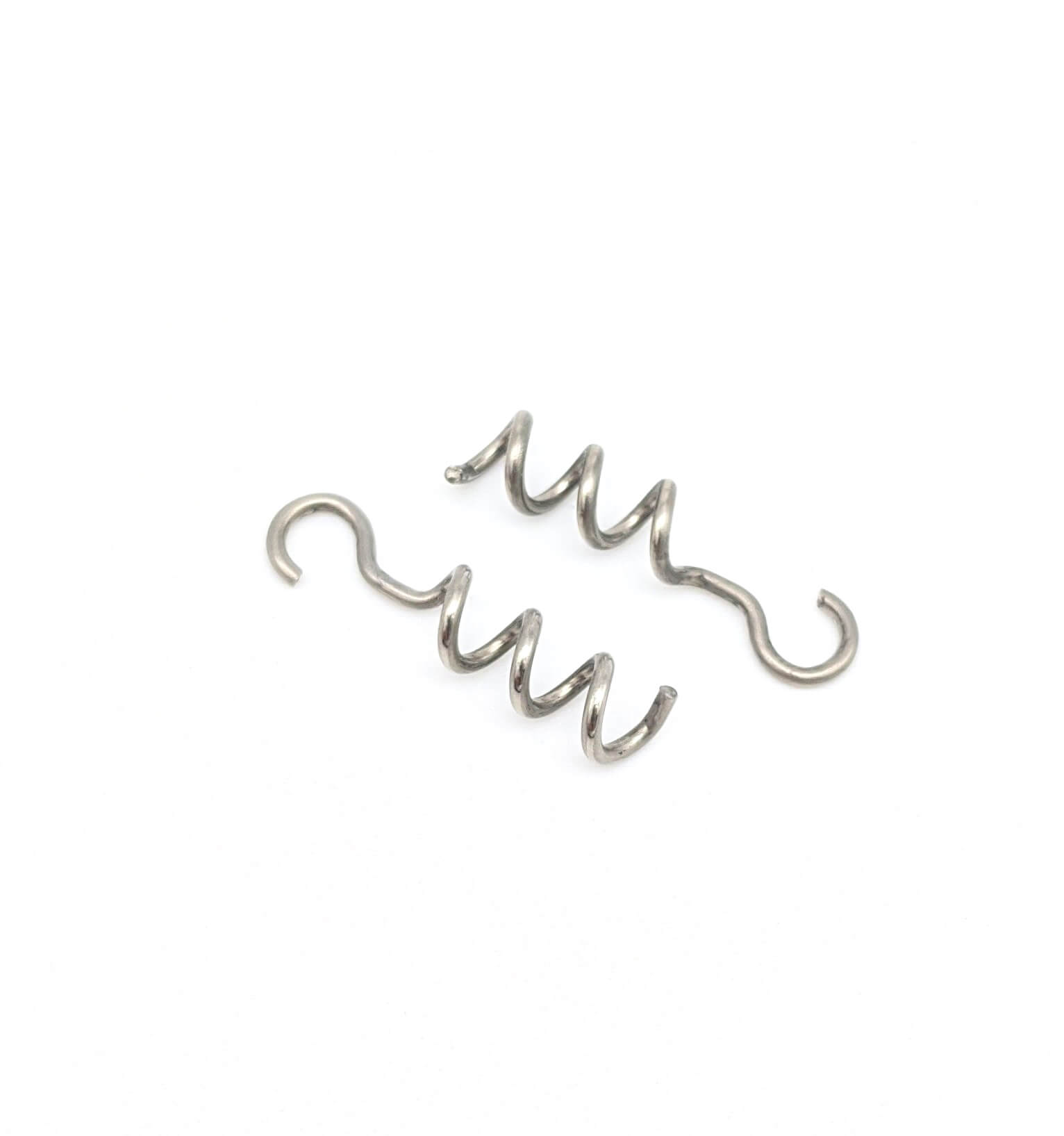

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are ubiquitous in our world, silently powering everything from car suspensions to door hinges. But have you ever wondered about the limits of their compression? Understanding the maximum compression

Springs are ubiquitous in our world, silently powering everything from car suspensions to door hinges. But have you ever wondered about the limits of their compression? Understanding the maximum compression a spring can handle is crucial for ensuring its safety and performance. This guide will delve into the intricacies of spring compression, equipping you with the knowledge to determine the maximum compression limit for your specific spring.

The heart of spring functionality lies in its ability to store and release energy through compression. When you push down on a spring, you're essentially compressing its coils, storing potential energy. The more you compress it, the more energy it stores, but this potential energy has limits. Pushing past those limits can lead to spring deformation, permanent damage, or even failure.

Determining the maximum compression of a spring isn't a one-size-fits-all endeavor. It depends on several key factors:

Several methods can be employed to find the maximum compression limit for a spring. Here are some popular approaches:

When working with springs, safety should always be paramount. Exceeding a spring's compression limit can lead to several potential risks:

Ensuring safe compression is essential for maximizing the lifespan and reliability of springs. Using the appropriate methods and carefully considering the factors outlined above will help you avoid potential issues and maintain optimal performance.

Remember, a well-compressed spring is a happy spring, ready to perform its vital duties without compromising safety.

Determining the maximum compression of a spring is a crucial step in designing and using spring-based systems. By understanding the factors that influence compression limits, you can ensure that your springs operate safely and efficiently, contributing to the reliability and longevity of your applications. Always prioritize safety when working with springs, and remember that a well-compressed spring is a happy spring, ready to power your world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.