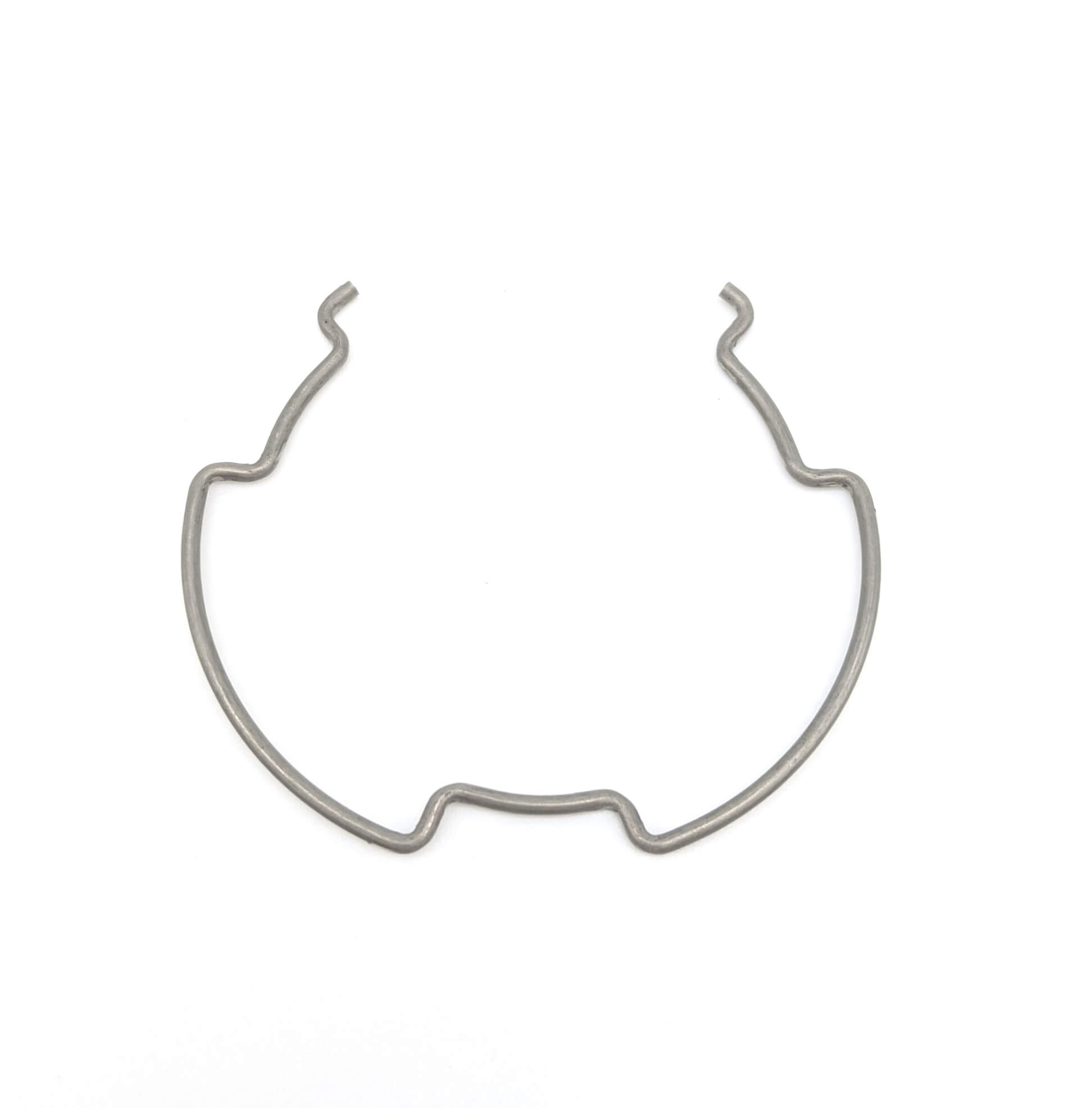

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous coiled wonders, are essential components in countless mechanical and engineering applications. From the suspension systems of our cars to the delicate mechanisms of clocks, springs play a

Springs, those ubiquitous coiled wonders, are essential components in countless mechanical and engineering applications. From the suspension systems of our cars to the delicate mechanisms of clocks, springs play a vital role in storing and releasing energy, absorbing shocks, and providing restoring forces. Understanding spring compression is fundamental to designing and implementing these applications effectively. This comprehensive guide delves into the intricacies of spring compression, exploring its principles, equations, and practical considerations.

A spring, at its core, is a flexible elastic element designed to resist deformation. When a force is applied to a spring, it compresses, storing potential energy within its coils. This stored energy is then released when the force is removed, causing the spring to return to its original length. This fundamental behavior is governed by Hooke's Law, a cornerstone principle in spring mechanics.

Hooke's Law states that the force required to compress or extend a spring is directly proportional to the displacement from its equilibrium position. Mathematically, this is expressed as:

F = -kx

Where:

- F is the force applied to the spring

- k is the spring constant, a measure of the spring's stiffness

- x is the displacement from the equilibrium position (compression or extension)

The negative sign indicates that the force acts in the opposite direction to the displacement. This means that if you compress the spring (positive x), the force exerted by the spring will be in the opposite direction (negative F) trying to restore the spring to its original length.

The spring constant (k) is a crucial parameter that determines the stiffness of a spring. A higher spring constant indicates a stiffer spring, requiring more force to achieve a given compression or extension. The value of k depends on the material, the geometry of the spring (wire diameter, coil diameter, number of coils), and the manufacturing process.

To calculate the compression of a spring under a given force, we can rearrange Hooke's Law:

x = -F/k

This equation tells us that the compression (x) is directly proportional to the applied force (F) and inversely proportional to the spring constant (k). This means that a higher force will result in a greater compression, while a stiffer spring (higher k) will compress less for the same force.

While Hooke's Law provides a fundamental understanding of spring behavior, there are several practical considerations to keep in mind when dealing with spring compression in real-world applications:

Spring compression finds widespread applications across diverse fields. Here are a few notable examples:

Understanding spring compression is crucial for engineers and designers working with mechanical systems. By grasping the fundamental principles, applying Hooke's Law, and considering practical factors such as spring limits, hysteresis, temperature effects, and fatigue, we can effectively design and implement spring-based solutions for a wide range of applications. As we navigate the complexities of modern engineering, mastering spring compression remains an essential skill for achieving successful and reliable outcomes.

In conclusion, spring compression is a fundamental concept in mechanical engineering, vital for understanding and designing a wide array of systems. From simple everyday objects to complex machinery, springs play a crucial role in providing restoring forces, absorbing shocks, and storing and releasing energy. By applying Hooke's Law and considering the practical factors that influence spring behavior, engineers can harness the power of spring compression to create innovative and reliable solutions.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.