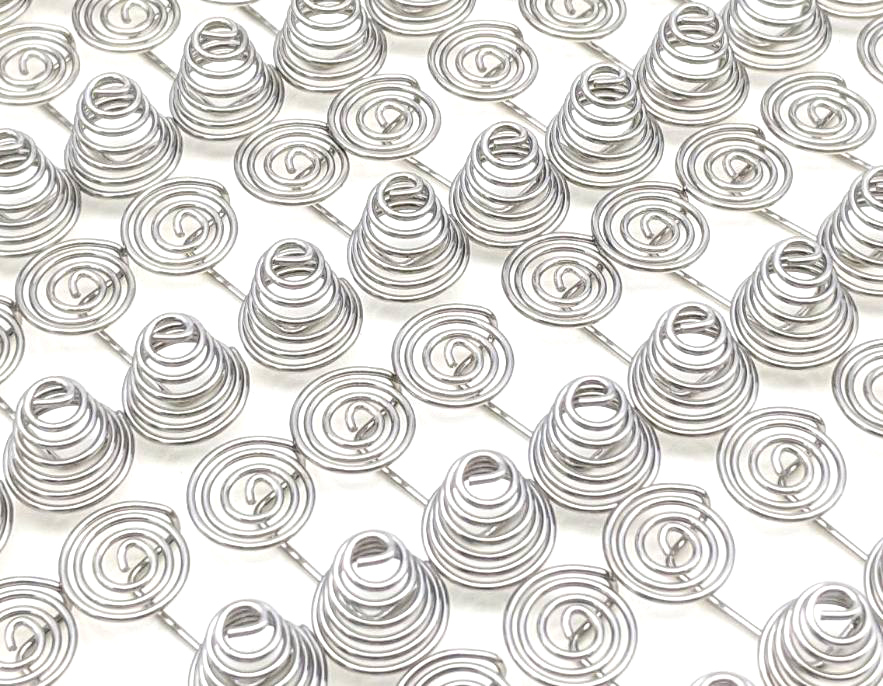

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs, those ubiquitous helical wonders, are found in countless applications, from the delicate mechanisms of watches to the robust suspensions of vehicles. A core concept in understanding spring behavior is

Springs, those ubiquitous helical wonders, are found in countless applications, from the delicate mechanisms of watches to the robust suspensions of vehicles. A core concept in understanding spring behavior is spring compression, which dictates how a spring reacts under applied force. This article delves into the spring compression formula, unraveling its secrets and showcasing its practicality in real-world scenarios.

Imagine a simple coil spring, ready to be squeezed. As you apply pressure, the spring compresses, storing energy within its tightly wound coils. This compression is directly related to the force you exert. The spring compression formula helps us quantify this relationship, allowing us to predict how much a spring will compress under a given load.

The spring compression formula is a fundamental equation that describes the relationship between force, spring constant, and compression distance. It is given by:

F = k * x

Where:

F = Force applied to the spring (measured in Newtons (N) or pounds-force (lbf)).

k = Spring constant (measured in N/m or lbf/in). The spring constant represents the stiffness of the spring. A higher spring constant indicates a stiffer spring that requires more force to compress.

x = Compression distance (measured in meters (m) or inches (in)). This is the amount by which the spring is compressed from its original length.

The spring constant, 'k', is a crucial parameter that embodies the spring's inherent stiffness. It's a measure of how much force is needed to compress the spring by a unit distance. Determining the spring constant is often the first step in applying the spring compression formula.

For many standard coil springs, the spring constant can be calculated using the following equation:

k = (G * d^4) / (8 * D^3 * n)

Where:

G = Shear modulus of elasticity of the spring material (measured in Pascals (Pa) or pounds per square inch (psi)). The shear modulus represents the material's resistance to deformation.

d = Diameter of the spring wire (measured in meters (m) or inches (in)).

D = Mean diameter of the spring coil (measured in meters (m) or inches (in)).

n = Number of active coils in the spring (a coil is considered active if it contributes to the spring's compression).

The spring compression formula finds widespread application across various engineering disciplines and industries:

Mechanical Engineering:

Design of suspension systems for vehicles, ensuring optimal ride comfort and handling.

Development of actuators and mechanisms in robotics and automation.

Analysis of spring-loaded systems in machinery and equipment, ensuring safe and efficient operation.

Civil Engineering:

Calculation of spring-supported structures, such as bridges and buildings, to withstand seismic loads.

Design of shock absorbers in earthquake-resistant buildings to minimize damage.

Aerospace Engineering:

Analysis of spring-loaded components in aircraft and spacecraft, ensuring reliable performance under extreme conditions.

The spring compression formula provides a foundational understanding, but real-world springs often exhibit more complex behaviors due to factors such as:

Non-linearity: For large compression distances, the linear relationship between force and compression can break down, especially for certain spring designs.

Material Properties: The shear modulus of the spring material can vary with temperature and other environmental factors.

Friction: Internal friction within the spring coils can dissipate energy, leading to slight deviations from the ideal formula.

When applying the spring compression formula, remember these practical tips:

Ensure you're using consistent units for all parameters (e.g., meters for distance, Newtons for force).

Pay close attention to the specific design of the spring, including the number of active coils and any unique characteristics.

Consider the limitations of the formula and account for factors such as non-linearity and friction when analyzing complex scenarios.

The spring compression formula is a valuable tool for understanding the behavior of springs under load. By grasping the fundamentals and considering practical factors, engineers and designers can effectively utilize this formula to achieve precise control over spring performance in a wide range of applications. From ensuring smooth vehicle rides to building resilient structures, the spring compression formula plays a vital role in shaping our technological world.

The spring compression formula, with its simplicity and wide applicability, empowers engineers and designers to make informed decisions when working with these essential components. By understanding this equation, we gain insight into the fascinating interplay of force, stiffness, and deformation that defines the world of springs.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.