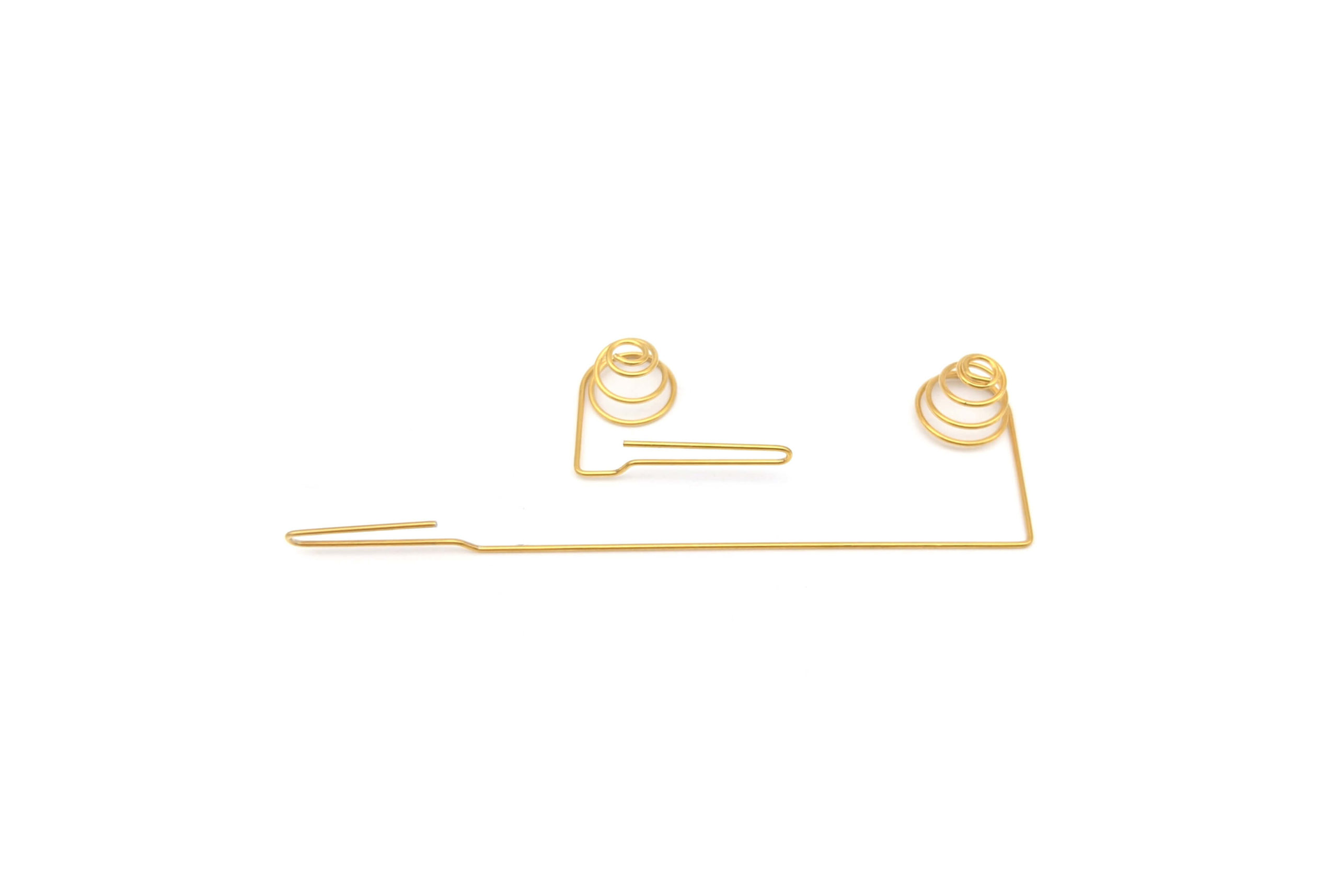

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Machined springs, often overlooked in the grand scheme of modern engineering, play a vital role in countless applications. These seemingly simple components, crafted from precise machining processes, are the backbone

Machined springs, often overlooked in the grand scheme of modern engineering, play a vital role in countless applications. These seemingly simple components, crafted from precise machining processes, are the backbone of countless devices, ensuring smooth operation, stability, and reliable performance. From the delicate workings of a wristwatch to the heavy-duty machinery of factories, machined springs are the unsung heroes, quietly and effectively fulfilling their crucial functions.

Machined springs are not simply coiled pieces of metal. Their creation is a meticulous process, demanding precision and expertise. The starting point is often a coil of high-quality spring wire, selected based on the specific requirements of the application. This wire is then fed into specialized machines that, with remarkable accuracy, cut, bend, and shape the metal into the desired spring form. The process is anything but simple. It requires a blend of engineering knowledge, technical skill, and careful attention to detail. Each spring is a testament to the craftsmanship involved, a tiny marvel of design and execution.

The beauty of machined springs lies in their adaptability. They can be crafted to meet a wide range of demands, from the most delicate to the most robust. Their strength, resilience, and ability to store and release energy make them indispensable in countless industries. They can be found in everything from medical devices and automotive components to aerospace applications and industrial machinery.

Machined springs offer a distinct advantage over their counterparts, particularly in applications where precision and reliability are paramount. Their inherent accuracy allows for precise control over spring characteristics like spring rate, load capacity, and fatigue resistance. This level of precision is often crucial for optimal performance and longevity in demanding environments.

Moreover, the machining process allows for the creation of intricate spring designs that would be impossible to achieve with other methods. This opens up a world of possibilities for engineers, enabling them to create springs with unique shapes, sizes, and functionalities. Whether it's a spring with a specific number of coils, a particular wire diameter, or a unique geometry, machined springs can be customized to meet almost any requirement.

The durability of machined springs is another key advantage. Their construction, involving carefully chosen materials and precise machining techniques, ensures exceptional strength and resilience. This is particularly important in applications where springs are subjected to constant stress, vibration, or extreme temperatures.

The applications of machined springs are vast and diverse. Their presence is felt in countless industries, silently supporting the smooth operation of machinery and devices we rely on daily.

In the automotive industry, machined springs play a crucial role in suspension systems, ensuring a smooth ride and proper handling. They are also used in clutches, brakes, and engine components, contributing to the overall efficiency and reliability of vehicles.

The medical field relies heavily on machined springs as well. They are found in medical devices like surgical instruments, prosthetic limbs, and even pacemakers, where precision and reliability are essential for patient safety and well-being.

Beyond these examples, machined springs are ubiquitous. They are used in consumer electronics, aerospace components, industrial machinery, and countless other applications. They are the backbone of our technological world, quietly ensuring the proper functioning of the devices and systems that shape our lives.

The demand for machined springs continues to grow as technology advances and new applications emerge. The increasing complexity of machinery and the need for greater precision are driving innovation in spring manufacturing, pushing the boundaries of what is possible. The development of new materials and advanced machining techniques is ensuring that machined springs will continue to be essential components in the future.

As engineers seek to create smaller, more efficient, and more reliable devices, machined springs will play an even more critical role. Their ability to be tailored to specific needs, their exceptional precision, and their unwavering durability make them invaluable tools for designers and manufacturers. Whether in the realm of microelectronics, medical devices, or the vast world of industrial machinery, machined springs are poised to continue their reign as the unsung heroes of modern engineering.

The next time you encounter a piece of machinery, a complex device, or even a simple household appliance, take a moment to appreciate the tiny, often invisible, machined spring that may be quietly working behind the scenes. These unassuming components are a testament to human ingenuity, a crucial element in our technological world, and a reminder that even the smallest parts can have a profound impact on our lives.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.