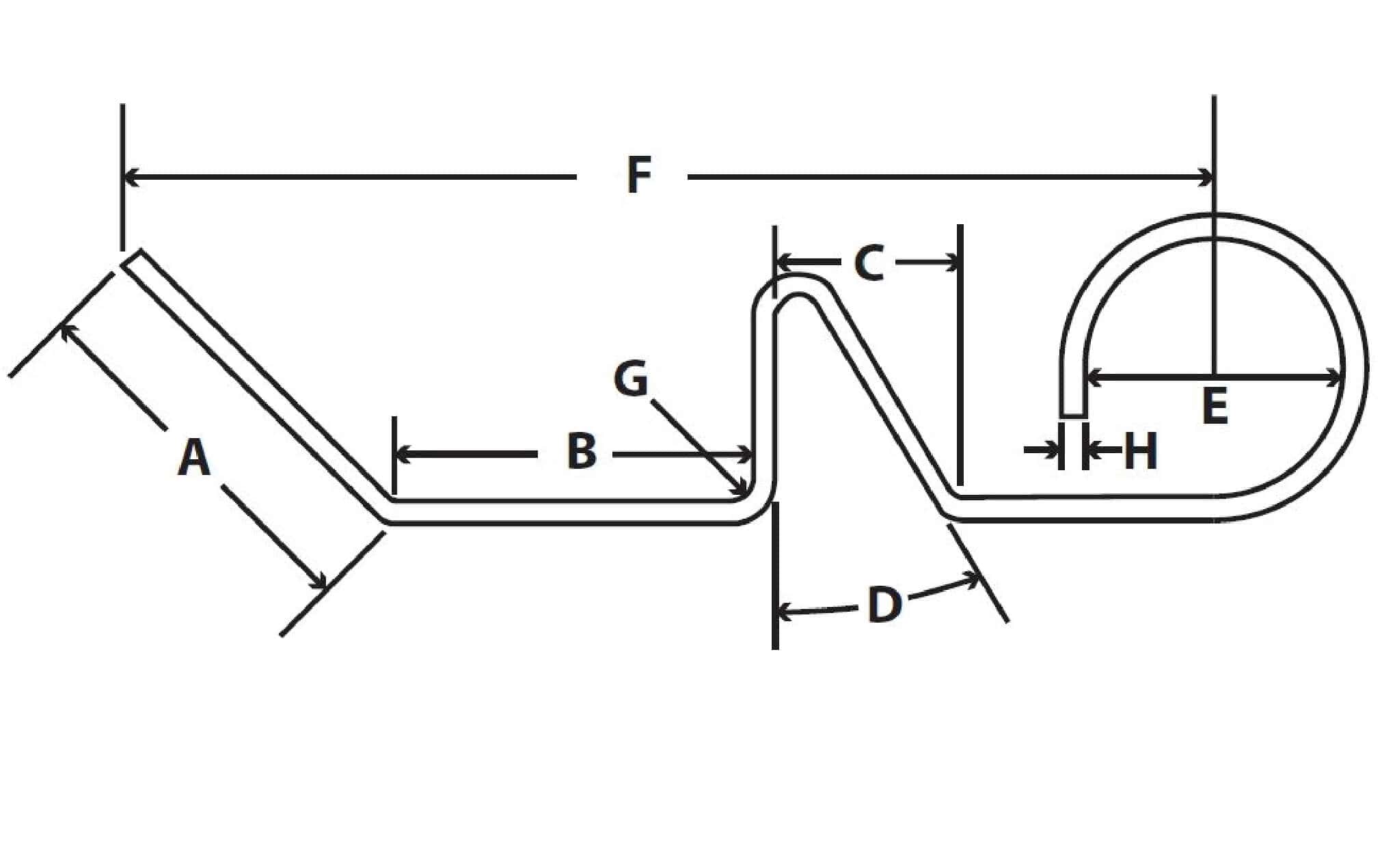

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, springs play a crucial role in countless applications, from simple door hinges to complex aerospace systems. While coil springs might be the first image

In the world of mechanical engineering, springs play a crucial role in countless applications, from simple door hinges to complex aerospace systems. While coil springs might be the first image that comes to mind, there's a whole other class of springs crafted with precision and sophistication: machined springs. Unlike their coiled counterparts, machined springs are not formed by winding wire but rather by meticulously shaping solid material, allowing for intricate designs and unparalleled control over their properties.

Machined springs, as their name suggests, are crafted through the precise removal of material from a solid block or bar using techniques like turning, milling, and grinding. This process allows for a level of customization that is simply not possible with coiled springs. Imagine springs with complex shapes, integrated features, and tailored stiffness profiles – this is the realm of machined springs.

Why go through the extra effort of machining a spring? The answer lies in the unique advantages they offer. Machined springs shine in applications demanding:

The choice of material for machined springs is paramount, impacting their performance, durability, and cost. Here's a look at some popular options:

The unique qualities of machined springs open up a vast array of applications, ranging from the mundane to the extraordinary. Some examples include:

The world of machined springs is constantly evolving, driven by advancements in materials science, manufacturing processes, and design software. Here are some trends shaping the future:

Machined springs, with their intricate designs, precise dimensions, and tailored properties, stand as a testament to the ingenuity of mechanical engineering. They empower innovation across a wide range of applications, from everyday objects to cutting-edge technologies. As materials science and manufacturing techniques advance, the role of machined springs will only continue to grow, shaping the future of design and engineering.

From simple door hinges to complex aerospace systems, machined springs are woven into the fabric of our world. Their precision engineering empowers innovation, ensuring reliability and performance across a vast array of applications. As we continue to push the boundaries of design and materials science, the humble machined spring will continue to play a pivotal role in shaping the future.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.