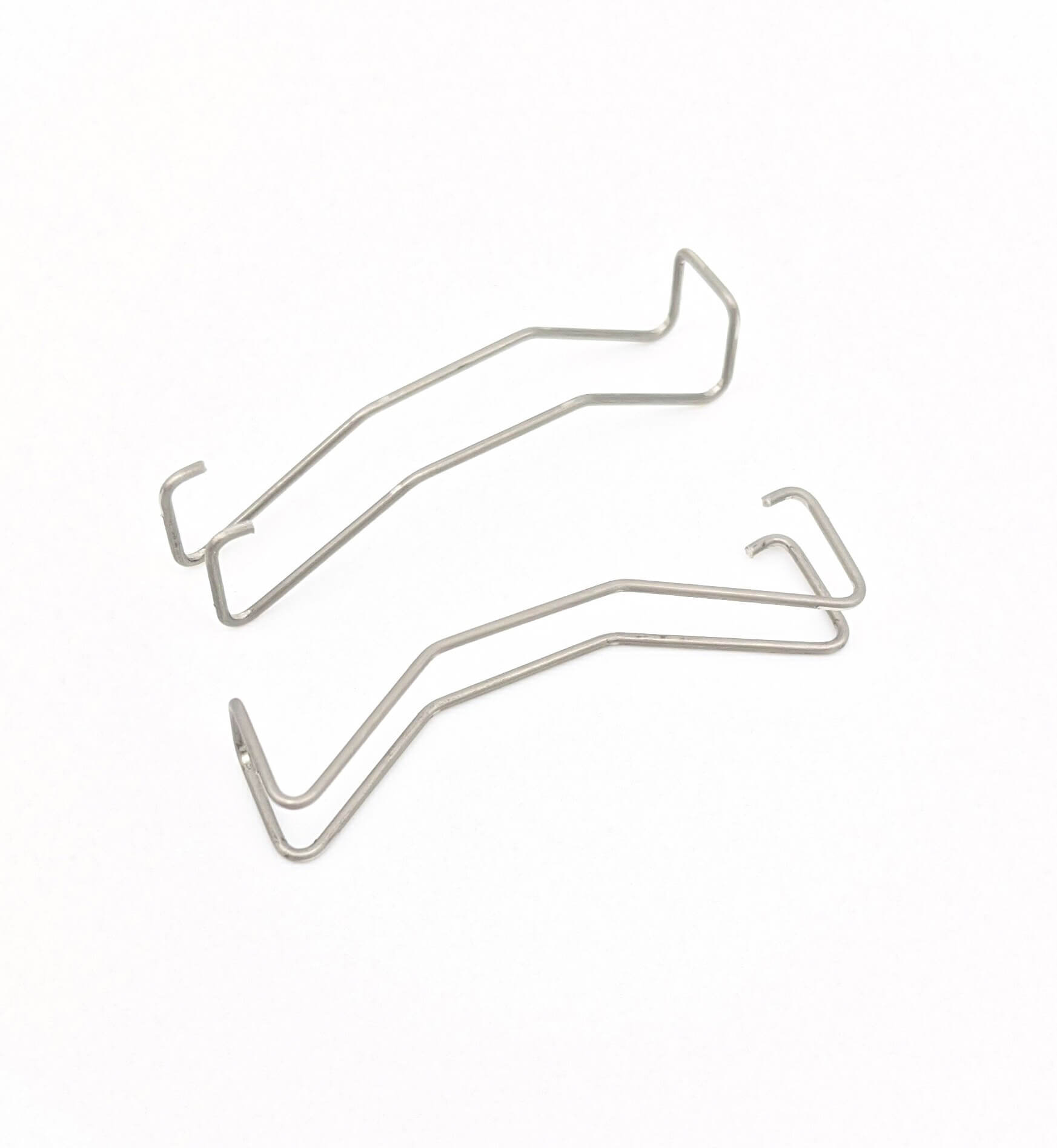

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Long compression springs, with their extended length and inherent ability to absorb high forces, are essential components in various mechanical systems. They provide reliable support, cushioning, and energy storage, making

Long compression springs, with their extended length and inherent ability to absorb high forces, are essential components in various mechanical systems. They provide reliable support, cushioning, and energy storage, making them valuable for diverse applications ranging from automotive to aerospace. This article delves into the intricacies of long compression springs, exploring their design considerations, material selection, common applications, and the benefits they offer.

Long compression springs, as the name suggests, are characterized by their extended length compared to standard compression springs. This elongated design allows them to absorb substantial forces while maintaining their structural integrity. Their construction involves tightly wound coils of spring wire, crafted from materials like steel, stainless steel, or alloys, depending on the specific application requirements.

The design of long compression springs is crucial for their performance. The key factors to consider include:

These design parameters are carefully balanced to achieve the desired spring characteristics for a given application.

The choice of material for a long compression spring is paramount, directly affecting its strength, durability, and performance in various environments. Common materials include:

The choice of material is determined by factors like the required spring rate, operating temperature, corrosive environment, and the spring's intended use.

Long compression springs find widespread applications across diverse industries, contributing to the smooth operation and reliability of numerous mechanical systems. Some prominent examples include:

Their versatility and ability to adapt to diverse needs make long compression springs invaluable across a wide range of applications.

Long compression springs offer several advantages that make them a preferred choice for various applications:

The combination of these benefits makes long compression springs a valuable component in countless mechanical systems.

Long compression springs, with their exceptional load-bearing capacity, energy storage capabilities, and durability, are indispensable elements in modern mechanical systems. Their widespread applications, ranging from automotive and aerospace to industrial equipment and consumer products, underscore their vital role in ensuring smooth operation, reliability, and safety. By understanding their design, material selection, and benefits, engineers can effectively leverage these springs to create innovative and efficient solutions across a vast spectrum of industries.

The next time you encounter a mechanism with a long, coiled component, remember that it might be a long compression spring quietly but effectively performing its crucial task. These springs are often unseen but always vital, contributing to the smooth operation and longevity of countless systems we rely on every day.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.