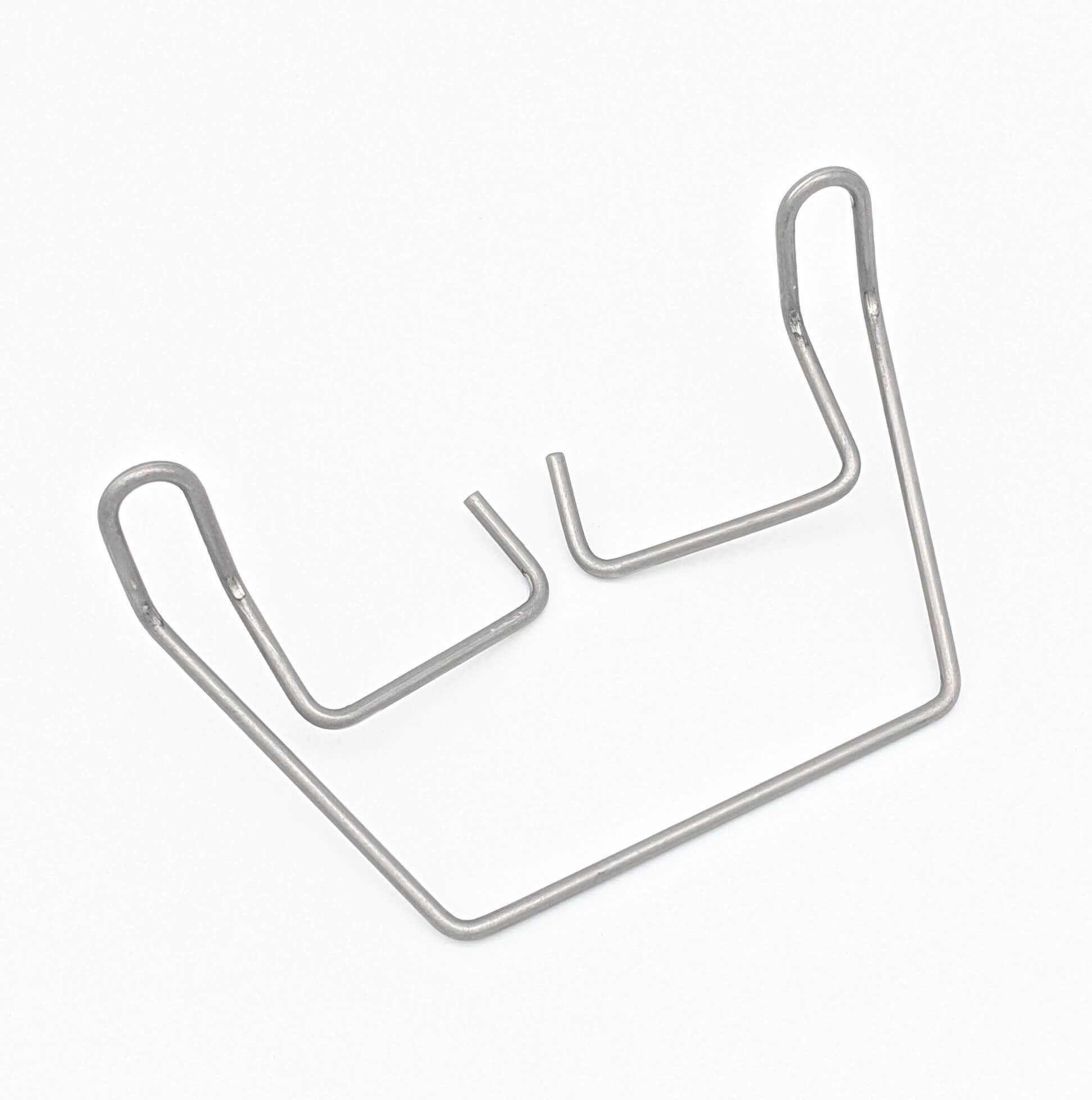

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of engineering, compression springs are often seen as mundane components, but their significance in various applications cannot be understated. Long compression springs, in particular, play a crucial

In the world of engineering, compression springs are often seen as mundane components, but their significance in various applications cannot be understated. Long compression springs, in particular, play a crucial role in providing consistent and reliable force, especially in situations where space constraints are a concern. These versatile springs are ubiquitous in numerous industries, from automotive to aerospace to consumer products, silently contributing to the smooth operation of countless machines and devices. This article delves into the intricacies of long compression springs, exploring their unique characteristics, applications, and the factors that influence their selection and design.

Long compression springs, as the name suggests, are characterized by their extended length compared to their diameter. This elongated design allows them to accommodate larger deflections while maintaining their spring constant, a critical factor in many applications. These springs are typically made from high-quality spring steel, which offers excellent resilience and resistance to fatigue. Their construction involves tightly wound coils that, when compressed, store potential energy, which is then released to perform a specific mechanical function.

The most notable characteristic of long compression springs is their ability to generate high forces even under substantial compression. This makes them ideal for applications where significant force is required to overcome resistance or to provide a specific level of tension. Furthermore, their ability to absorb shocks and vibrations makes them invaluable for reducing noise and extending the lifespan of mechanical systems.

Long compression springs find widespread use in a myriad of industries and applications. Here are some prominent examples:

Automotive Industry: Long compression springs are indispensable in automotive suspension systems, where they provide the necessary force to support the weight of the vehicle and maintain ride comfort. They are also used in engine valve systems, clutch mechanisms, and seat adjustment mechanisms.

Aerospace Industry: In aircraft and spacecraft, long compression springs play a crucial role in landing gear systems, door actuators, and other critical components where high forces and reliable performance are paramount.

Consumer Products: Long compression springs are present in various consumer products, such as office chairs, furniture, toys, and sporting equipment. They are also found in door hinges, spring-loaded handles, and other mechanisms where force and resilience are required.

Industrial Machinery: Long compression springs are integral to the operation of industrial machines, including presses, conveyors, and packaging equipment. They are used to provide counterbalancing forces, assist in material handling, and enhance the efficiency of various processes.

The selection and design of long compression springs are influenced by several factors that dictate their performance and suitability for a specific application.

Spring Rate: The spring rate, also known as the spring constant, is a critical parameter that determines the amount of force required to compress the spring by a unit length. A higher spring rate indicates a stiffer spring, requiring more force for compression.

Free Length: The free length of a long compression spring is its overall length when it is not under any load. It is crucial to consider the available space and the desired deflection when selecting a spring with an appropriate free length.

Wire Diameter: The diameter of the wire used to construct the spring plays a significant role in its strength and load-bearing capacity. A larger wire diameter generally results in a stronger and more durable spring.

Number of Coils: The number of coils in the spring directly affects its spring rate. A higher number of coils results in a lower spring rate.

Material: The material of the spring is crucial for its resilience, fatigue resistance, and overall durability. High-quality spring steel is commonly used for its excellent mechanical properties.

Like any engineering component, long compression springs have their own advantages and disadvantages:

* High force generation under compression

* Excellent shock and vibration absorption

* Relatively low cost

* Widely available in various sizes and materials

* Potential for buckling at high compression levels

* Limited deflection range compared to shorter springs

* Can be bulky in some applications

Long compression springs are unsung heroes of mechanical design, quietly contributing to the smooth operation of countless machines and devices. Their ability to provide consistent and reliable force, combined with their shock absorption properties, makes them invaluable in numerous applications. Understanding their unique characteristics, applications, and the factors that influence their selection and design is crucial for engineers seeking to optimize their mechanical systems for reliability, efficiency, and longevity. As technology continues to advance, the importance of long compression springs is likely to remain paramount, ensuring that mechanical systems continue to operate smoothly and efficiently, both on Earth and beyond.

In the ever-evolving world of engineering, long compression springs remain a vital component, contributing to the functionality and reliability of countless mechanical systems. Their versatility, coupled with their ability to provide consistent force and absorb shocks, ensures their enduring role in a wide range of industries. As technology advances and new challenges emerge, the importance of long compression springs is likely to remain significant, making them an essential part of the mechanical design landscape for years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.