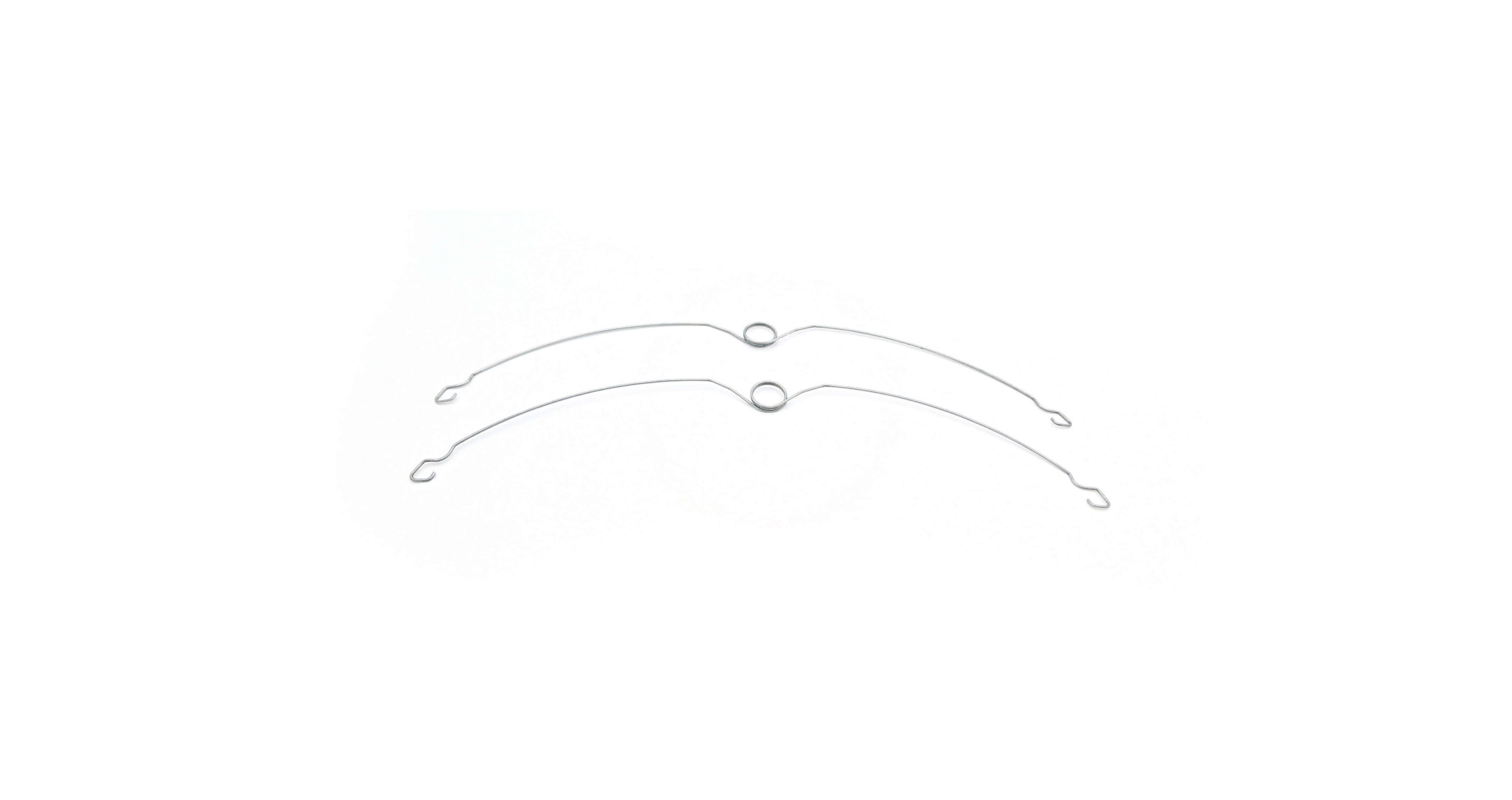

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of engineering and design, long compression springs often go unnoticed. They're the silent workhorses that provide support, stability, and resilience in countless applications. From the humble garage

In the world of engineering and design, long compression springs often go unnoticed. They're the silent workhorses that provide support, stability, and resilience in countless applications. From the humble garage door to the intricate mechanisms of industrial machinery, these springs play a crucial role in our daily lives. Their unassuming nature belies their remarkable ability to absorb shock, store energy, and provide consistent force, making them essential components in a wide range of products and systems.

Long compression springs, as their name suggests, are coil springs designed to withstand significant compressive forces. They are characterized by their extended length compared to their diameter, allowing them to absorb substantial energy and provide a considerable amount of force over a longer distance. This unique combination of attributes makes them ideal for various applications where reliable support, shock absorption, and consistent force are paramount.

At the heart of every long compression spring lies a carefully engineered coil of spring steel. The coil is wound with a specific pitch, which determines the spring's initial length and rate of compression. The spring's rate refers to the amount of force required to compress the spring by a specific distance. This rate is crucial for determining the spring's performance in various applications.

The choice of spring steel is critical, as it dictates the spring's strength, durability, and resistance to fatigue. High-quality spring steel is designed to withstand repeated compression and extension cycles without permanent deformation, ensuring long-term reliability. When selecting a long compression spring, factors such as the required load capacity, spring rate, and operating environment must be carefully considered.

Long compression springs find applications in a diverse array of industries and products, quietly enhancing performance and ensuring smooth operation. Some of the most common applications include:

Long compression springs are indispensable in automotive applications, where they provide crucial support to suspension systems, ensuring ride comfort and handling stability. They act as shock absorbers, absorbing bumps and vibrations, providing a smoother ride for passengers. The long length of these springs allows for a larger range of motion, ensuring proper suspension travel even over rough terrain.

In industrial settings, long compression springs are vital for various machinery and equipment, providing essential support, damping vibrations, and facilitating smooth operation. They can be found in lifting equipment, presses, conveyors, and other heavy-duty machines. The long length of these springs ensures a steady force over a longer stroke, enhancing the efficiency and safety of industrial processes.

Long compression springs are commonly used in appliances such as refrigerators, washing machines, and dryers, providing tension and support for various components. They ensure smooth operation and prevent the appliance from malfunctioning, enhancing their overall performance and durability.

Long compression springs are integral to the construction of comfortable and supportive furniture and bedding. They provide cushioning and resilience, enhancing seating comfort and promoting a restful sleep. In mattresses, these springs offer independent support, ensuring a comfortable and customized sleep experience.

In the realm of sporting goods, long compression springs find applications in equipment such as trampolines, archery bows, and even golf clubs. They contribute to the equipment's responsiveness and durability, enhancing performance and ensuring a safe and enjoyable experience for users.

The popularity of long compression springs stems from their numerous advantages, making them a preferred choice in various applications:

Long compression springs are designed to handle significant compressive forces, making them suitable for applications requiring substantial support and strength. Their extended length allows for a larger surface area to distribute the load, reducing stress on the spring material.

The long, helical design of these springs enables them to effectively absorb shock and vibrations, mitigating damage to surrounding components and enhancing the overall performance of the system. They can absorb and release energy, ensuring smooth and controlled movement, particularly in applications subject to impact loads.

Long compression springs are renowned for their consistency and reliability. They offer a predictable and consistent force output, making them ideal for applications demanding accuracy and precision. Their high-quality spring steel construction ensures long-term durability, even under harsh operating conditions.

Long compression springs are available in a wide range of sizes, spring rates, and materials, allowing them to be tailored to specific application requirements. This versatility makes them adaptable to a wide range of designs and configurations.

Choosing the right long compression spring is essential for optimal performance and longevity. Several factors need to be considered when selecting a spring for a specific application:

Determine the maximum load that the spring will be subjected to. This will dictate the spring's diameter, wire gauge, and the number of coils required.

The spring rate dictates the amount of force required to compress the spring by a specific distance. The chosen spring rate should be appropriate for the application's requirements and the desired amount of deflection.

The operating environment, including temperature, humidity, and corrosive agents, can influence the spring's performance and longevity. Select a spring material and coating that can withstand the specific environmental conditions.

The spring's length, diameter, and wire gauge need to be compatible with the available space and the surrounding components. The spring must be able to fit within the allotted space without interfering with other parts.

The spring material and design should ensure long-term durability and resistance to fatigue, even under repeated compression cycles. The spring should maintain its performance over an extended period without experiencing permanent deformation.

Long compression springs are often the unseen heroes of everyday life, playing a crucial role in countless applications. Their ability to absorb shock, store energy, and provide consistent force makes them essential components in automobiles, industrial machinery, appliances, furniture, sporting goods, and many other products and systems.

Their long length allows for a larger range of motion and higher load capacity, making them particularly valuable in applications requiring robust support, shock absorption, and reliable performance. Understanding the characteristics, advantages, and factors to consider when selecting a long compression spring can significantly enhance the efficiency, safety, and longevity of various products and systems.

In conclusion, long compression springs are versatile and essential components that contribute significantly to the performance and reliability of various products and systems. Their ability to absorb shock, store energy, and provide consistent force makes them valuable tools in various industries, ensuring smooth operation and enhancing the user experience.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.