Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

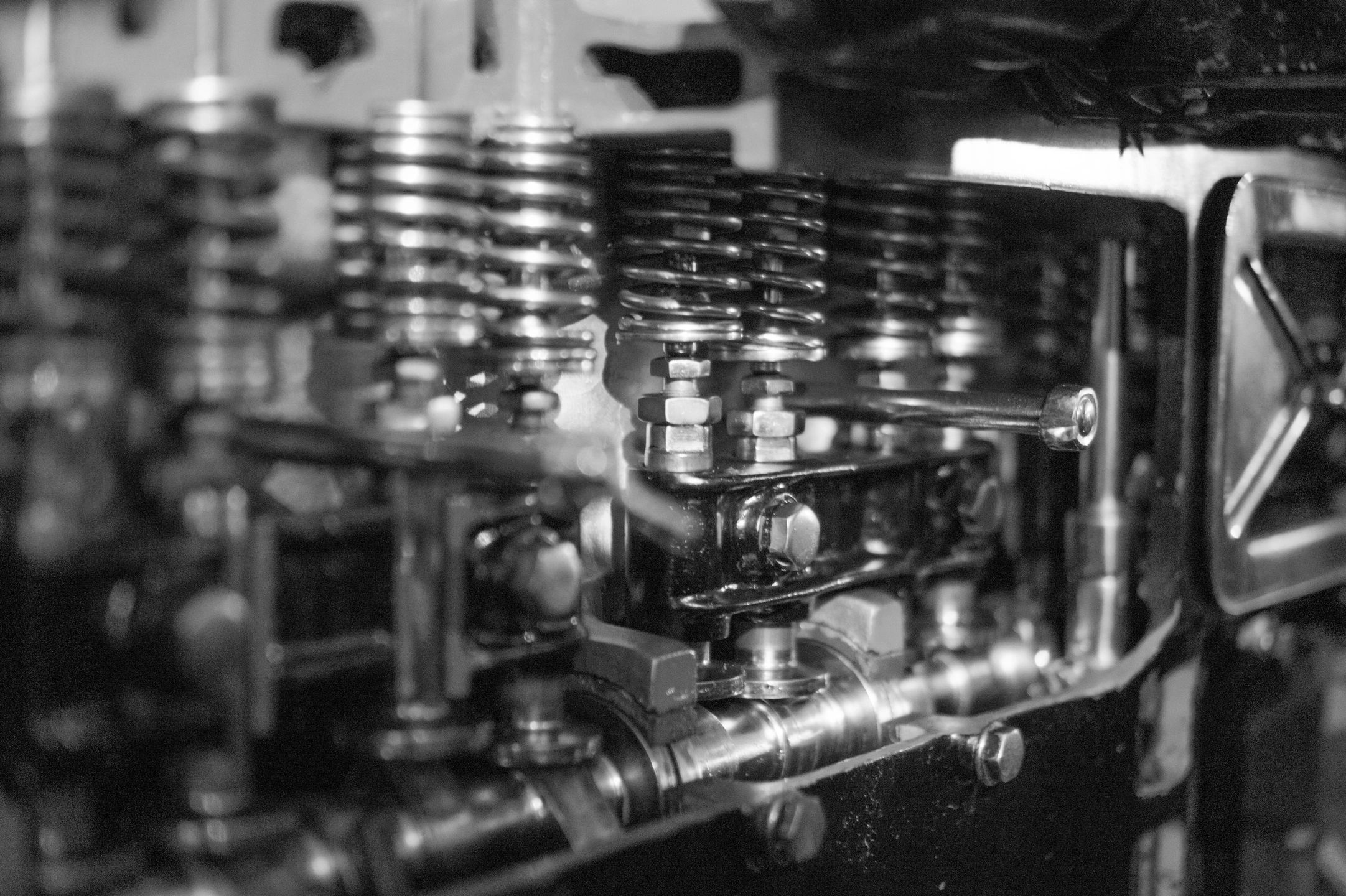

Linear wave springs, also known as wave springs, are a unique and versatile type of spring that offer numerous advantages over traditional helical springs. They are characterized by their distinct

Linear wave springs, also known as wave springs, are a unique and versatile type of spring that offer numerous advantages over traditional helical springs. They are characterized by their distinct wave-like shape, which allows them to provide consistent force over a longer deflection range, making them ideal for various applications where space is limited or a specific force profile is required. This article delves into the intricacies of linear wave springs, exploring their design, materials, benefits, and applications. Let's embark on a journey to understand the fascinating world of linear wave springs.

Linear wave springs, unlike their helical counterparts, do not rely on coil-to-coil contact to generate force. Instead, they utilize a series of interconnected waves, each designed to flex and deform under load. This unique design enables them to achieve a high spring rate within a compact footprint, making them particularly suitable for applications where space is a constraint. Think of them as a miniature accordion, expanding and contracting to absorb and release energy.

The wave-like construction of these springs gives them several inherent advantages over traditional helical springs. They offer greater deflection capabilities, meaning they can absorb more energy before reaching their load limit. Additionally, they can achieve a more consistent spring rate throughout their deflection range, ensuring predictable performance even under varying loads. This consistent force characteristic makes them highly desirable in applications demanding precise control and reliable operation.

The material selection for linear wave springs is crucial to their performance and longevity. High-strength steel alloys are the most common choice due to their excellent combination of strength, resilience, and fatigue resistance. These materials can withstand repeated compression and decompression cycles without compromising their structural integrity, ensuring the spring's durability over time.

However, specific applications might necessitate the use of alternative materials like stainless steel for improved corrosion resistance in harsh environments or special alloys for applications demanding specific temperature resistance or electrical conductivity.

Linear wave springs offer a compelling set of benefits that make them a preferred choice for various engineering applications. Here's a glimpse into their advantages:

The unique properties of linear wave springs have propelled them into a wide range of applications across various industries. Let's explore some prominent examples:

Linear wave springs represent a significant advancement in spring technology, offering a compelling combination of space-saving design, high spring rate, consistent force, and long service life. Their versatile nature has made them indispensable in diverse applications, ranging from automotive and aerospace to medical devices and consumer products. As technology continues to evolve, we can expect linear wave springs to play an increasingly vital role in shaping the future of engineering.

The journey into the world of linear wave springs has revealed their immense potential for various applications. Their ability to deliver consistent force, high spring rates, and long service life in a compact package sets them apart as a versatile solution for modern engineering challenges. As we delve deeper into the intricacies of spring technology, linear wave springs will continue to emerge as a valuable tool in shaping innovative solutions for a wide array of industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.