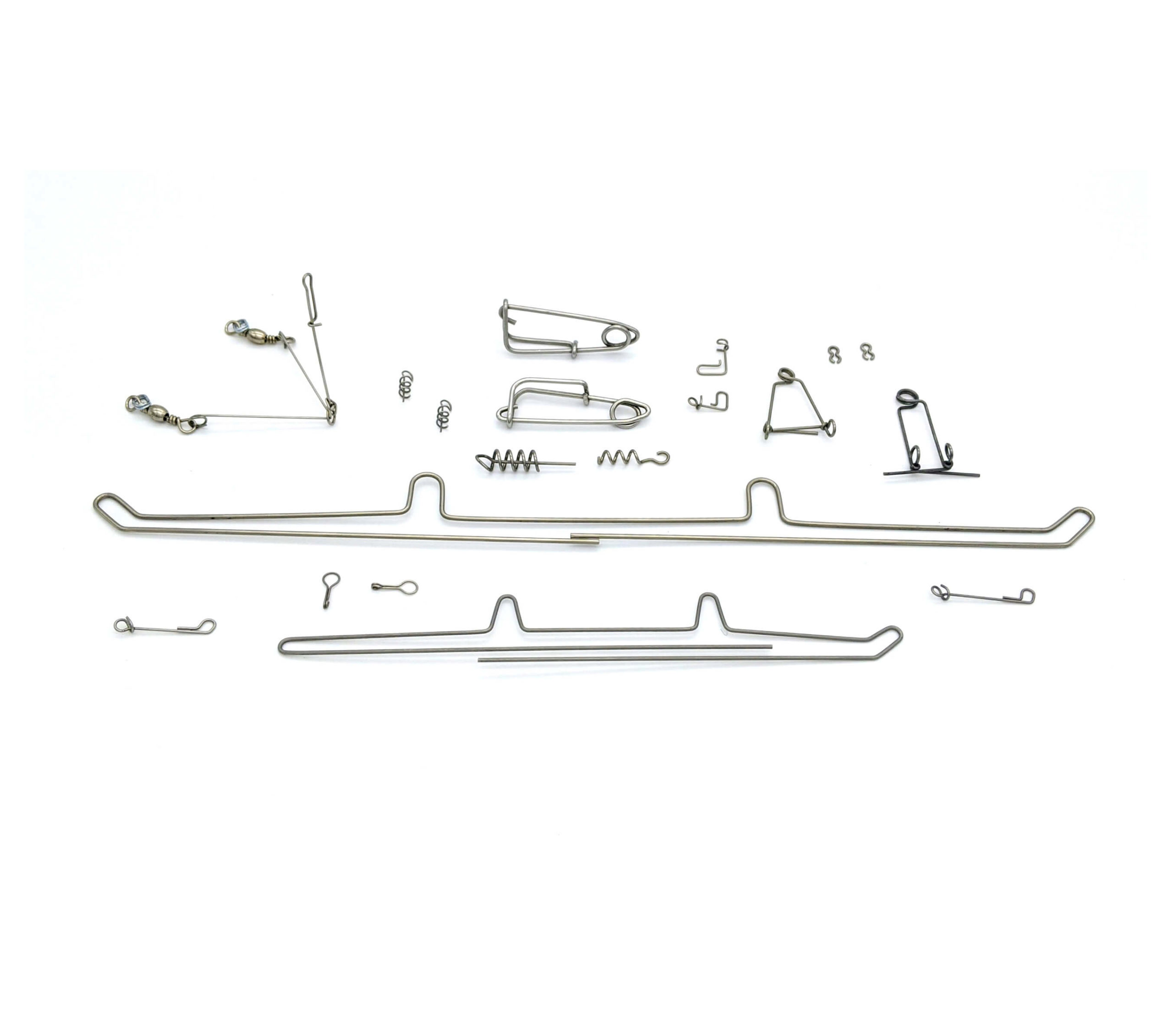

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Linear wave springs, also known as wave springs, are a relatively new type of spring that has quickly gained popularity for its unique advantages. These springs, characterized by their distinct

Linear wave springs, also known as wave springs, are a relatively new type of spring that has quickly gained popularity for its unique advantages. These springs, characterized by their distinct wave-like shape, offer a range of benefits over traditional helical springs, making them a compelling option for diverse applications across various industries. Let's dive into the fascinating world of linear wave springs and explore the reasons why they're making waves in the engineering world.

Linear wave springs are a type of spring that consists of a series of interconnected, wave-shaped elements, often made from high-quality spring steel. Unlike conventional helical springs, which rely on a coil to store and release energy, linear wave springs harness their unique geometry to achieve similar functionality. This wave-like configuration allows them to compress and extend in a linear fashion, providing a consistent force output over a defined range of motion.

Linear wave springs boast a number of advantages over traditional helical springs, making them an attractive choice for a wide range of applications. Here are some of the key benefits:

1. High Load Capacity: Linear wave springs are remarkably strong and resilient, capable of supporting significantly higher loads compared to conventional helical springs of similar size. This makes them ideal for situations where space is limited but high force requirements are necessary.

2. Compact Design: Due to their unique wave-like structure, linear wave springs can achieve a high spring rate within a compact footprint. This space-saving design is a major advantage, particularly in situations where space is at a premium, such as in miniature devices or tight mechanical assemblies.

3. Long Service Life: Linear wave springs are highly durable and resistant to fatigue, ensuring a significantly longer operational lifespan compared to traditional helical springs. This longevity makes them a cost-effective solution for applications that require consistent performance over extended periods.

4. Reduced Friction: Linear wave springs exhibit lower friction compared to helical springs, especially in high-load applications. This reduced friction translates to lower energy losses and smoother operation, enhancing the overall efficiency of the system they are integrated into.

5. Uniform Force Distribution: The wave-like design of linear wave springs ensures a more consistent and uniform force distribution throughout the compression cycle. This even force distribution contributes to increased accuracy and reduced wear and tear, enhancing the reliability of the system.

6. Varied Spring Rates: Linear wave springs offer greater flexibility in terms of spring rates. By adjusting the design parameters, such as the wave height, wave length, and material type, engineers can customize the spring rate to meet the specific requirements of the application.

7. Enhanced Corrosion Resistance: Linear wave springs are often manufactured from corrosion-resistant materials, like stainless steel, making them suitable for use in environments with high humidity or exposure to corrosive elements.

8. Temperature Stability: Linear wave springs retain their performance characteristics over a wider temperature range compared to some traditional helical springs. This makes them suitable for applications that experience fluctuating temperatures, such as in automotive or aerospace industries.

The unique advantages of linear wave springs have opened up a wide range of applications across various industries. These springs are proving to be a valuable solution for:

1. Automotive Industry: Linear wave springs find applications in automotive suspension systems, shock absorbers, and clutch systems. They can also be used in engine valve springs, contributing to improved performance and fuel efficiency.

2. Aerospace Industry: Linear wave springs are used in landing gear systems, aircraft control systems, and satellite systems. Their ability to withstand extreme loads and temperatures makes them well-suited for aerospace applications.

3. Medical Devices: Linear wave springs find application in medical devices such as surgical instruments, prosthetic limbs, and medical pumps. Their high load capacity, compact size, and biocompatibility make them ideal for these sensitive applications.

4. Electronics Industry: Linear wave springs are used in electronic devices such as cell phones, laptops, and tablets. Their ability to provide a reliable and compact spring force makes them suitable for mechanisms like buttons, switches, and keypads.

5. Industrial Machinery: Linear wave springs are used in various industrial machinery, including hydraulic presses, manufacturing equipment, and construction machinery. Their high load capacity and durability make them well-suited for heavy-duty applications.

6. Consumer Products: Linear wave springs can be found in a wide range of consumer products, such as toys, office equipment, and sporting goods. Their compact size, durability, and ability to provide a consistent force make them ideal for these applications.

Linear wave springs represent a significant advancement in spring technology. They offer a combination of benefits, including high load capacity, compact design, long service life, reduced friction, and a wide range of spring rates. These advantages have made them a compelling choice for a variety of applications across diverse industries. As technology continues to advance, it is likely that linear wave springs will play an increasingly important role in shaping the future of engineering and design.

As linear wave springs continue to gain popularity and evolve, expect to see even more innovative applications emerge. With their unique combination of strength, durability, and space-saving design, linear wave springs are poised to revolutionize spring technology and drive innovation in various industries for years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.