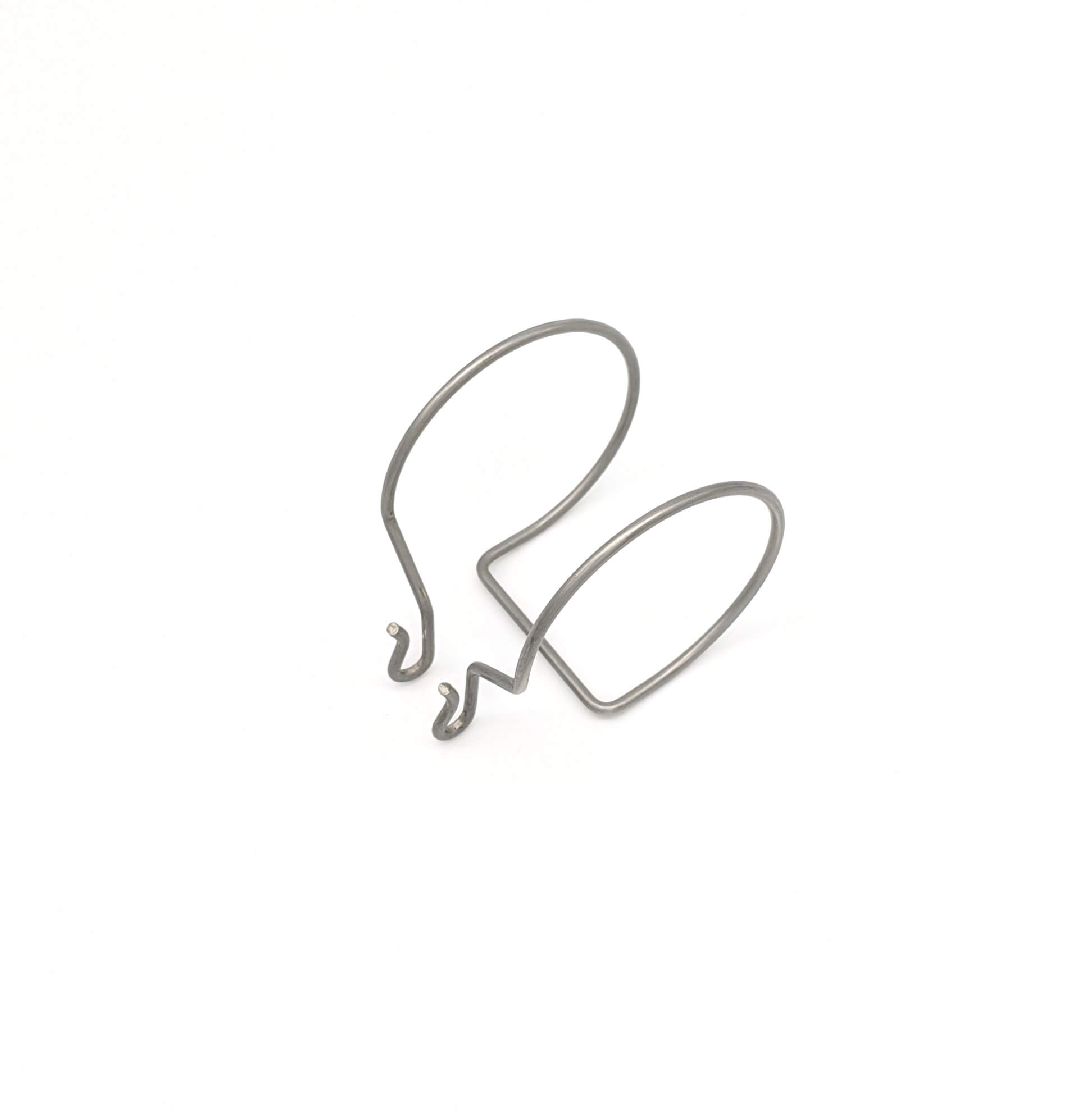

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Linear wave springs, also known as constant force springs, are a unique type of spring characterized by their linear force-deflection curve. Unlike traditional helical springs that exhibit a nonlinear force

Linear wave springs, also known as constant force springs, are a unique type of spring characterized by their linear force-deflection curve. Unlike traditional helical springs that exhibit a nonlinear force response, linear wave springs offer consistent force output throughout their compression range. This distinctive property makes them ideal for applications requiring precise force control, such as in medical devices, aerospace components, and industrial machinery. This article provides a detailed guide to linear wave springs, delving into their design principles, diverse applications, and numerous advantages.

Linear wave springs are crafted from thin, flat metal strips that are precisely shaped into a series of waves. When compressed, these waves deform in a controlled manner, generating a constant force over a defined distance. This constant force characteristic is a key advantage of linear wave springs, setting them apart from traditional helical springs. The force generated by a linear wave spring is directly proportional to its cross-sectional area and the material's elastic modulus, while the spring rate is determined by the wave geometry and the number of active waves in the spring. The design of linear wave springs allows for customization in terms of force, stroke, and spring rate, making them highly versatile for a wide range of applications.

Linear wave springs offer numerous advantages over conventional helical springs, making them a preferred choice in various industries. These advantages include:

The distinctive properties of linear wave springs make them ideal for a wide array of applications across diverse industries. Some key applications include:

Designing linear wave springs involves considering several factors, including:

Linear wave springs are a versatile and innovative spring solution that offers numerous advantages over traditional helical springs. Their constant force output, high force density, long service life, and wide operating temperature range make them ideal for various demanding applications. As technology continues to advance, linear wave springs are likely to play an even more prominent role in diverse industries, contributing to advancements in medical devices, aerospace components, industrial machinery, and consumer products. Understanding the design principles, applications, and benefits of linear wave springs can empower engineers and designers to optimize their designs and achieve exceptional performance in various fields.

In conclusion, linear wave springs are an exceptional spring solution offering a unique combination of constant force output, high force density, long service life, and design flexibility. These characteristics make them highly sought-after in numerous industries, revolutionizing applications from medical devices and aerospace components to industrial machinery and consumer products. As technology continues to evolve, linear wave springs are poised to become even more ubiquitous, playing a pivotal role in shaping the future of mechanical systems and products.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.