Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Large compression springs, often overlooked in the grand scheme of mechanical components, play a crucial role in ensuring the smooth and efficient operation of heavy-duty machinery. From industrial presses to

Large compression springs, often overlooked in the grand scheme of mechanical components, play a crucial role in ensuring the smooth and efficient operation of heavy-duty machinery. From industrial presses to automotive suspension systems, these robust coils are the unsung heroes, silently absorbing shock and storing energy to drive powerful movements. This article delves into the world of large compression springs, exploring their design, materials, applications, and the factors that make them indispensable in various industries.

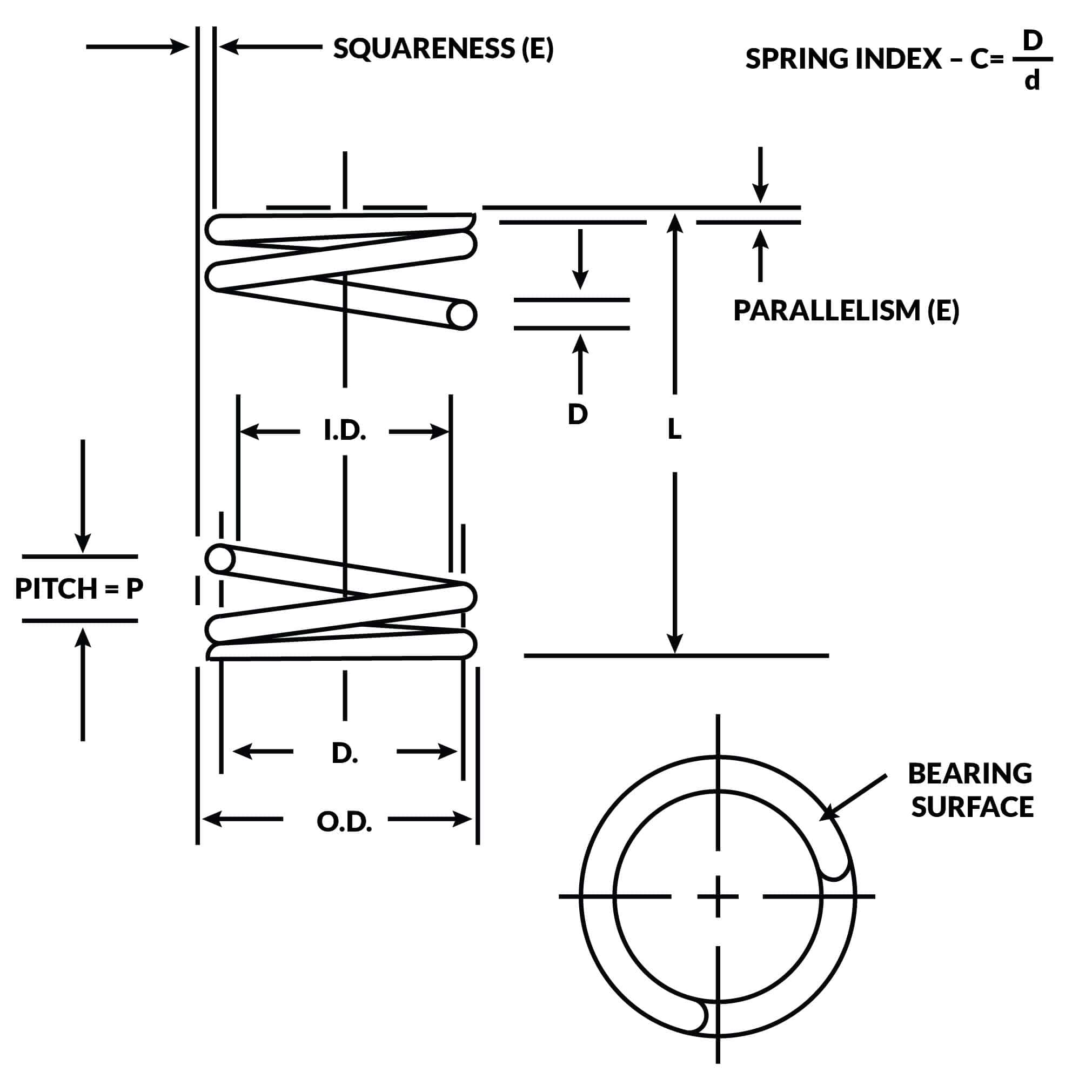

Large compression springs are, as the name suggests, springs designed to withstand considerable compressive forces. They are characterized by their large diameter, high spring rate, and substantial wire thickness, allowing them to handle heavy loads and endure demanding operating conditions. Think of them as the strong, silent guardians of mechanical systems, providing resilience and durability where it matters most.

The design of a large compression spring is a delicate balancing act between strength, flexibility, and space constraints. The number of coils, wire diameter, spring index, and material selection all contribute to its performance. Materials like high-carbon steel, stainless steel, and even exotic alloys like Inconel are chosen based on the application's specific requirements, factoring in corrosion resistance, temperature tolerance, and fatigue life.

The sheer size of large compression springs dictates their use in heavy-duty applications where smaller springs simply wouldn't suffice. They find their niche in industries like:

Selecting the right large compression spring involves several crucial considerations. These include:

In high-stakes applications, the reliability of large compression springs is paramount. Selecting springs from reputable manufacturers and adhering to proper installation and maintenance practices are crucial to ensure optimal performance and longevity. It's not just about the spring itself, but the entire system that surrounds it, from the materials used to the design and manufacturing process.

As technology continues to evolve, so too will the demands placed on large compression springs. Advancements in materials science, manufacturing processes, and design optimization are paving the way for even stronger, more efficient, and longer-lasting springs. Innovation is key to ensuring these silent powerhouses continue to drive progress in various industries, delivering robust performance and reliability in even the most demanding applications.

Large compression springs are essential components in heavy-duty applications, providing crucial shock absorption, energy storage, and force generation. Their size, strength, and reliability make them indispensable in industries where performance and safety are paramount. By understanding their design, materials, applications, and the factors influencing their selection, engineers and designers can leverage the power of large compression springs to drive innovation and enhance the performance of mechanical systems across various sectors.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.