Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Large compression springs are often the unsung heroes of various industries, silently supporting and stabilizing critical components. These robust coiled metal marvels can handle immense forces, absorbing energy and returning

Large compression springs are often the unsung heroes of various industries, silently supporting and stabilizing critical components. These robust coiled metal marvels can handle immense forces, absorbing energy and returning it with unwavering reliability. From heavy-duty machinery and automotive systems to aerospace applications and beyond, large compression springs play a vital role in ensuring smooth, efficient, and safe operation. But what exactly makes these springs so special, and how do they contribute to the success of diverse engineering endeavors? Let's delve into the fascinating world of large compression springs and explore their unique properties, applications, and the critical factors that influence their design and performance.

Imagine a spring so powerful it can withstand the weight of a car or the force of a heavy-duty industrial press. That's the essence of large compression springs. These seemingly simple coiled metal structures are marvels of engineering, capable of storing and releasing vast amounts of energy while maintaining their integrity under extreme conditions. The key to their impressive strength lies in their design and the materials used to construct them.

Large compression springs typically employ high-tensile strength steels, often with a special tempering process to enhance their resilience and fatigue resistance. The coils are carefully wound and often have a specific pitch and wire diameter to optimize their performance. The spring's ability to absorb and release energy is directly proportional to its stiffness, a factor that is influenced by its geometry and the material's properties.

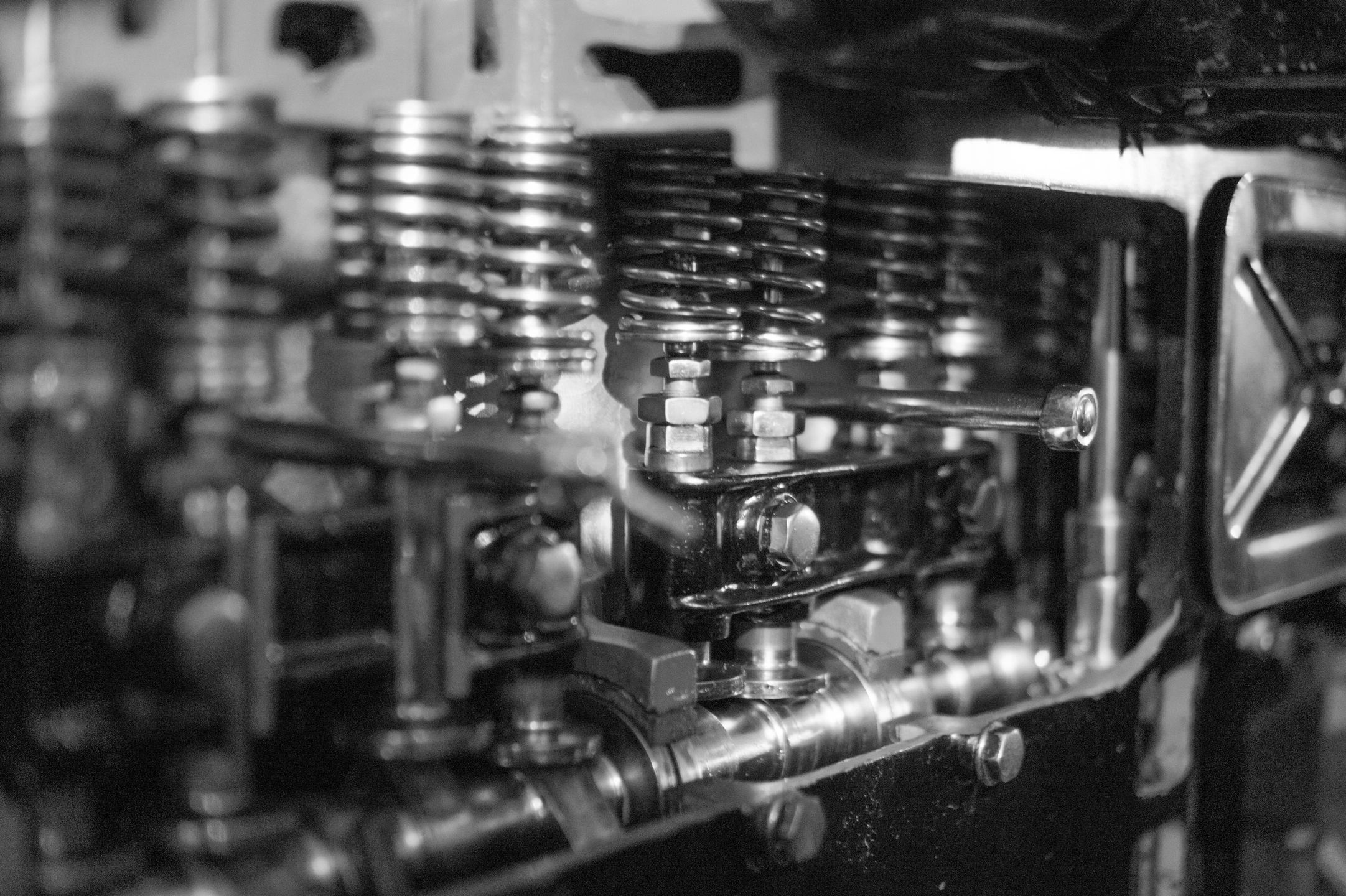

One of the most remarkable features of large compression springs is their ability to return to their original shape after repeated compression and decompression cycles. This characteristic, known as resilience, is crucial for applications that require consistent performance under demanding conditions. Moreover, large compression springs are designed to handle heavy loads and provide reliable support for various mechanical systems. This makes them invaluable in industries like automotive manufacturing, where they are used in suspension systems, engine components, and other critical assemblies.

The versatility of large compression springs is truly astounding. Their strength, resilience, and ability to store and release energy make them suitable for an incredibly wide range of applications across multiple sectors.

In the automotive industry, large compression springs are vital components in suspension systems, ensuring a smooth and comfortable ride while absorbing shocks and vibrations from the road. They also play a role in engine components, such as valve springs, which regulate the opening and closing of valves, and in clutches, where they provide the necessary force for smooth engagement and disengagement.

Beyond automotive, large compression springs find their niche in heavy machinery and industrial equipment. In construction and mining equipment, they are used to support heavy loads, power hydraulic systems, and provide essential force for operations such as crushing and drilling. In industrial presses and stamping machines, large compression springs deliver the precise force needed for shaping and forming materials.

In aerospace engineering, large compression springs are crucial for landing gear systems and other critical components that require resilience and reliability under extreme conditions. They also play a role in satellite launch vehicles and other space applications, where their ability to store and release energy is essential for precise maneuverability and deployment.

Even in everyday products, large compression springs often go unnoticed, silently performing their duties. For example, they are used in furniture, appliances, and sporting equipment, providing support and stability while enhancing functionality.

Designing large compression springs is a complex task that involves a deep understanding of material science, mechanics, and the specific requirements of the application. Several key factors influence the design and performance of these robust springs:

**1. Material Selection:** The choice of material is paramount. High-tensile strength steels are often preferred for their strength, resilience, and fatigue resistance. The material's properties, such as yield strength, ultimate tensile strength, and fatigue limit, directly impact the spring's performance.

**2. Coil Geometry:** The number of coils, wire diameter, coil pitch, and end configuration are critical factors in determining the spring's stiffness, load capacity, and resilience.

**3. Spring Rate:** The spring rate, often expressed in pounds per inch or kilograms per centimeter, represents the spring's stiffness and its ability to resist compression. This factor is crucial for applications where precise force control is essential.

**4. Load Capacity:** The load capacity, or maximum weight the spring can withstand before permanent deformation, is a vital parameter for ensuring safety and reliability.

**5. Fatigue Life:** The fatigue life of a spring represents the number of compression and decompression cycles it can endure before failure. Large compression springs are designed to withstand thousands, if not millions, of cycles, making them highly reliable for long-term operation.

**6. Environmental Considerations:** The operating environment can significantly impact the performance of a large compression spring. Factors such as temperature, humidity, and exposure to corrosive elements must be carefully considered during the design process.

While strength and resilience are essential attributes of large compression springs, quality and longevity are equally important for ensuring reliable performance.

Manufacturers often employ strict quality control measures to ensure that large compression springs meet rigorous specifications. These measures include thorough inspection processes, material testing, and performance evaluations to guarantee that the springs meet or exceed industry standards.

Furthermore, proper maintenance and care play a crucial role in extending the lifespan of large compression springs. Regular inspections for wear and tear, proper lubrication, and adherence to recommended operating conditions can help prevent premature failure and ensure long-term performance.

Large compression springs have a long history of innovation and adaptation, evolving alongside the demands of various industries. As technology advances and new materials emerge, we can expect to see further advancements in the design and performance of these essential components.

One area of potential innovation lies in the development of lighter, yet equally strong, materials that can enhance efficiency and reduce weight in applications such as aerospace and automotive. Additionally, advancements in manufacturing processes, such as additive manufacturing (3D printing), have the potential to create highly customized and optimized compression springs with complex geometries and unique properties.

As engineers continue to push the boundaries of design and materials, large compression springs will undoubtedly continue to play a critical role in shaping the future of numerous industries, silently supporting and enabling the advancements that drive progress across the globe.

Large compression springs are the unsung heroes of modern engineering, embodying strength, resilience, and enduring performance. Their versatility, coupled with the continuous advancements in materials and manufacturing processes, ensures that these robust components will continue to be essential for countless applications, powering innovation and progress for years to come. As we continue to explore new frontiers in technology and push the limits of what's possible, large compression springs stand ready to support us every step of the way.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.