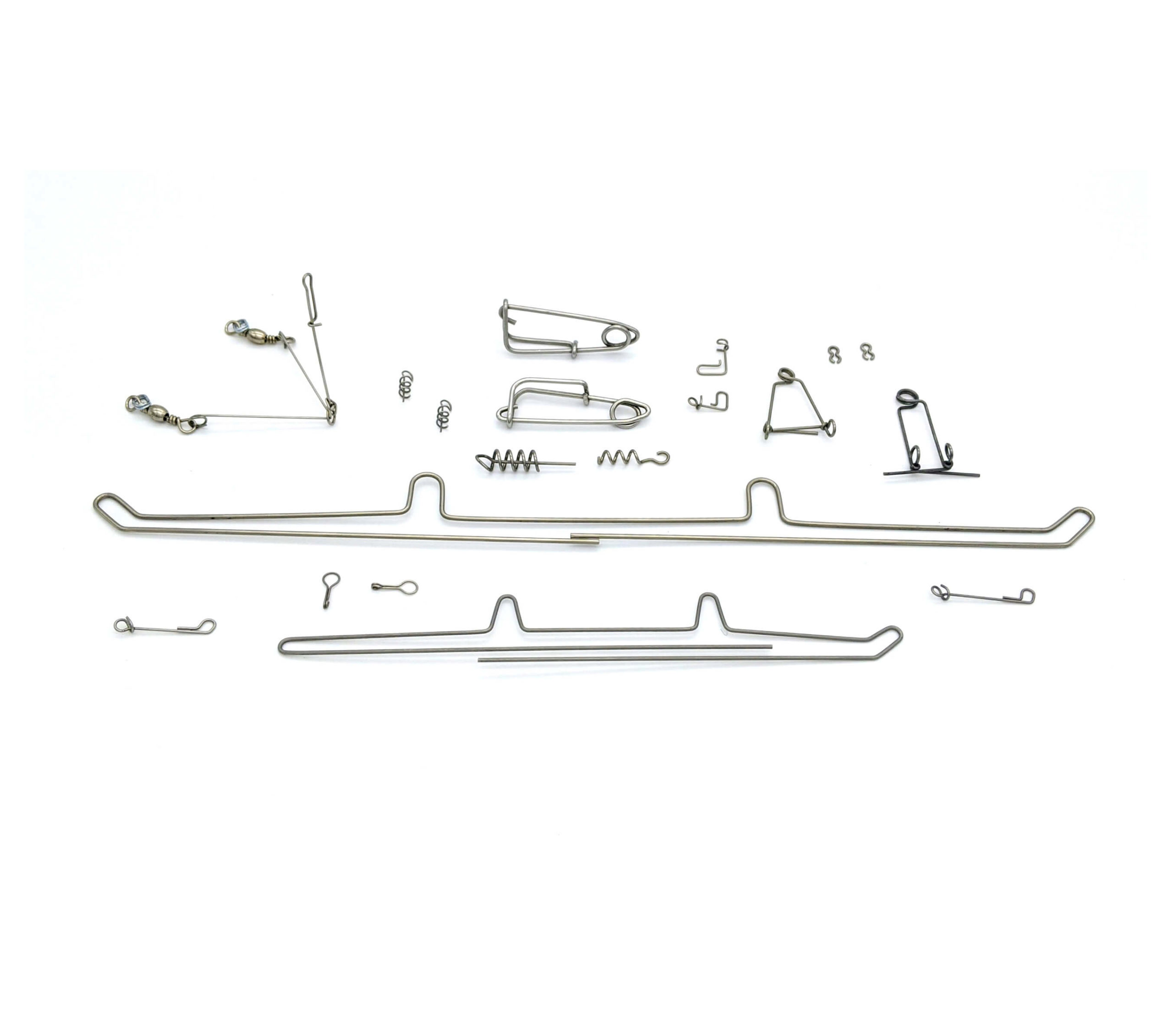

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Inconl wave springs, known for their exceptional resilience and durability, are specialized types of springs that offer a unique combination of flexibility and strength. This comprehensive guide delves into the

Inconl wave springs, known for their exceptional resilience and durability, are specialized types of springs that offer a unique combination of flexibility and strength. This comprehensive guide delves into the world of Inconl wave springs, exploring their key characteristics, advantages, and diverse applications. We'll uncover why these springs are so highly valued in demanding industrial settings, where reliability and performance are paramount.

Inconl wave springs are a distinct class of springs engineered from Inconl, a nickel-chromium-iron alloy renowned for its exceptional resistance to corrosion, high temperatures, and harsh environments. They are characterized by their unique wave-like design, which provides a high spring rate and a compact size, making them ideal for applications where space is limited.

Inconl wave springs are created by a specialized process that involves forming the Inconl material into a series of precise waves or curves. This intricate design allows the spring to flex and compress efficiently, offering superior performance under demanding conditions. The wave design enables the spring to store and release energy effectively, contributing to its exceptional efficiency and longevity.

Inconl wave springs stand out due to their numerous advantages that make them a preferred choice in a wide array of industries. Here are some of their key benefits:

Inconl wave springs find diverse applications in various industries where their exceptional properties are highly valued. Some notable examples include:

Selecting the appropriate Inconl wave spring for your application is crucial to ensure optimal performance and longevity. Here are some key factors to consider:

Inconl wave springs offer an exceptional combination of strength, resilience, and corrosion resistance, making them a reliable choice for various demanding applications. Their compact size, high spring rate, and extended service life contribute to their popularity in diverse industries. When selecting an Inconl wave spring, carefully consider the load requirements, deflection range, operating environment, and space constraints to ensure optimal performance and longevity. By understanding their properties and benefits, engineers can confidently incorporate Inconl wave springs into their designs, fostering innovation and efficiency in a wide range of applications.

As you embark on your journey with Inconl wave springs, remember that they are more than just ordinary springs. They are a testament to the power of engineering, offering a blend of exceptional performance and reliability that empowers innovation across industries. Their adaptability and endurance make them an essential component in driving advancements in aerospace, automotive, medical, and other critical sectors. As you harness the potential of these remarkable springs, you'll contribute to a future where innovation meets resilience.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.