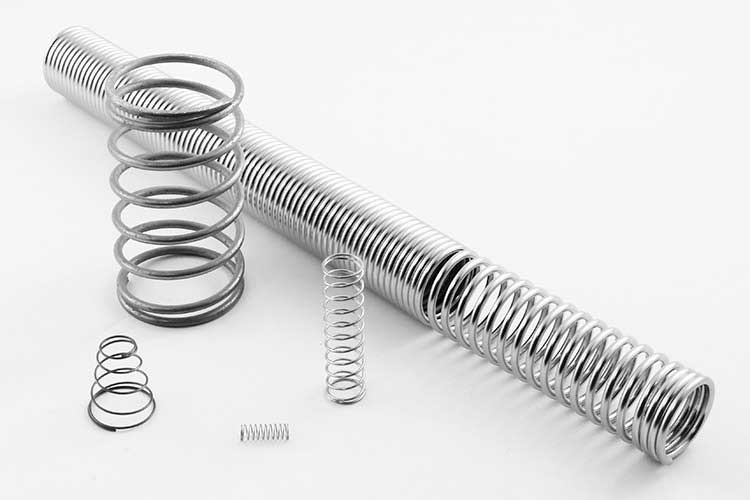

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Inconel wav springs, known for their exceptional high-temperature resistance and durability, are increasingly sought after in various industries. These springs, crafted from Inconel alloys, possess unique properties that make them

Inconel wav springs, known for their exceptional high-temperature resistance and durability, are increasingly sought after in various industries. These springs, crafted from Inconel alloys, possess unique properties that make them ideal for demanding applications, particularly in environments where conventional materials falter. This article delves into the intricacies of Inconel wav springs, exploring their composition, advantages, and common applications, providing insights into why they are becoming the go-to solution for engineers and designers seeking high-performance spring solutions.

Inconel wav springs, as the name suggests, are crafted from Inconel alloys, a family of nickel-chromium-based superalloys renowned for their exceptional resistance to corrosion, oxidation, and high temperatures. The 'wav' component refers to the unique wave-like configuration of the spring, a design element that contributes to its high fatigue strength and ability to withstand extreme loads.

The composition of Inconel alloys varies depending on the specific application. However, they typically contain a high percentage of nickel (around 60-80%), along with significant amounts of chromium (15-20%) and iron (5-10%). These elements, along with trace amounts of other metals like titanium, aluminum, and molybdenum, contribute to the exceptional properties of Inconel, making it a valuable material for demanding applications.

Inconel wav springs offer a compelling blend of advantages that set them apart from conventional spring materials. These benefits include:

The exceptional properties of Inconel wav springs have earned them a place in various critical applications across numerous industries. Some notable examples include:

Selecting the right Inconel wav spring for a particular application requires careful consideration of various factors. These include:

Inconel wav springs are truly remarkable examples of engineering ingenuity, offering unparalleled performance in high-temperature and demanding applications. Their exceptional properties, combined with their versatility and reliability, have solidified their position as the go-to solution for engineers and designers seeking high-performance spring solutions. As technology advances, we can expect to see even more innovative applications of Inconel wav springs, pushing the boundaries of what's possible in diverse industries. The future of these springs seems bright, fueled by their remarkable ability to withstand the most challenging environments and contribute to the success of various critical applications.

In conclusion, Inconel wav springs, with their remarkable high-temperature resistance, corrosion resistance, and fatigue strength, have become indispensable components in diverse industries. Their unique properties, combined with their versatility and reliability, have solidified their position as the go-to solution for demanding applications. As technology continues to advance, we can anticipate even more innovative applications of Inconel wav springs, showcasing their ability to withstand the most challenging environments and contribute to the success of various critical applications.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.