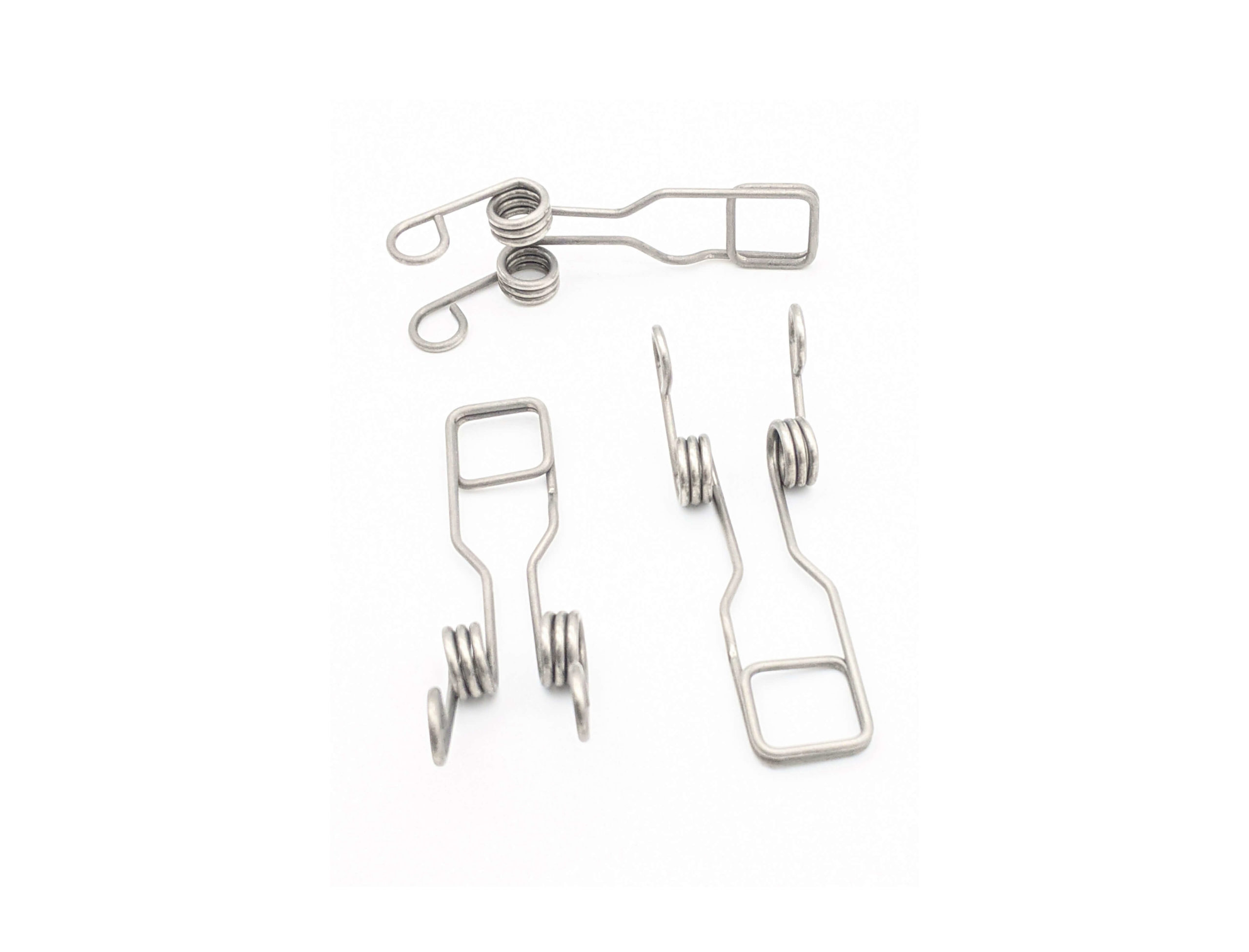

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are ubiquitous in engineering and everyday life, providing force, motion, and energy storage. Understanding how to determine a spring's maximum compression is crucial for safe and effective design. This

Springs are ubiquitous in engineering and everyday life, providing force, motion, and energy storage. Understanding how to determine a spring's maximum compression is crucial for safe and effective design. This guide will walk you through the process of finding this critical parameter, considering factors such as spring rate, material properties, and safety margins. We'll delve into the theoretical principles and practical considerations involved, empowering you to make informed decisions for your spring-based projects.

The maximum compression of a spring represents the limit to which it can be compressed before experiencing permanent deformation or failure. Exceeding this limit can lead to a loss of spring functionality, potential for injury, and even catastrophic component failure. To determine the maximum compression, we need to consider several factors that govern spring behavior.

There are several key factors that play a role in determining the maximum compression of a spring:

There are several methods for determining the maximum compression of a spring, each with its own advantages and limitations.

This method is based on Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement from its equilibrium position. The equation for Hooke's Law is:

F = kx

Where:

To find the maximum compression (x_max), you need to know the maximum force (F_max) the spring can handle without permanent deformation. This maximum force can be determined from the spring material's yield strength and the cross-sectional area of the spring wire. Rearranging Hooke's Law, we get:

x_max = F_max / k

This method involves physically compressing the spring and measuring its displacement. You can use a load cell or a calibrated spring scale to apply a known force and measure the resulting compression. By incrementally increasing the force and recording the corresponding compression, you can plot a force-displacement curve. The point where the curve deviates significantly from a linear relationship indicates the spring's maximum compression limit.

FEA is a powerful computational tool used to simulate the behavior of complex structures under various loads. It provides a detailed analysis of the stress and strain distribution within the spring, allowing for accurate prediction of its maximum compression and potential failure points. FEA is particularly useful for complex spring designs or situations where experimental testing is impractical.

When determining the maximum compression of a spring, it's important to consider:

Determining the maximum compression of a spring is a critical aspect of safe and effective spring design. By understanding the factors that influence spring behavior and utilizing appropriate methods, engineers and makers can ensure that their spring-based systems operate reliably and within their intended performance limits. This knowledge is essential for optimizing performance, preventing failures, and achieving optimal results in a wide range of applications.

In conclusion, finding the maximum compression of a spring is crucial for ensuring safe and efficient operation. By understanding the interplay of spring rate, material properties, geometry, and safety factors, you can make informed decisions about how to design and utilize springs effectively in your projects. Remember to always prioritize safety, consider the specific application's requirements, and select springs that are well-suited to the intended loading conditions. With this knowledge, you can confidently design and implement spring-based systems that deliver reliable performance and enhance the functionality of your creations.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.