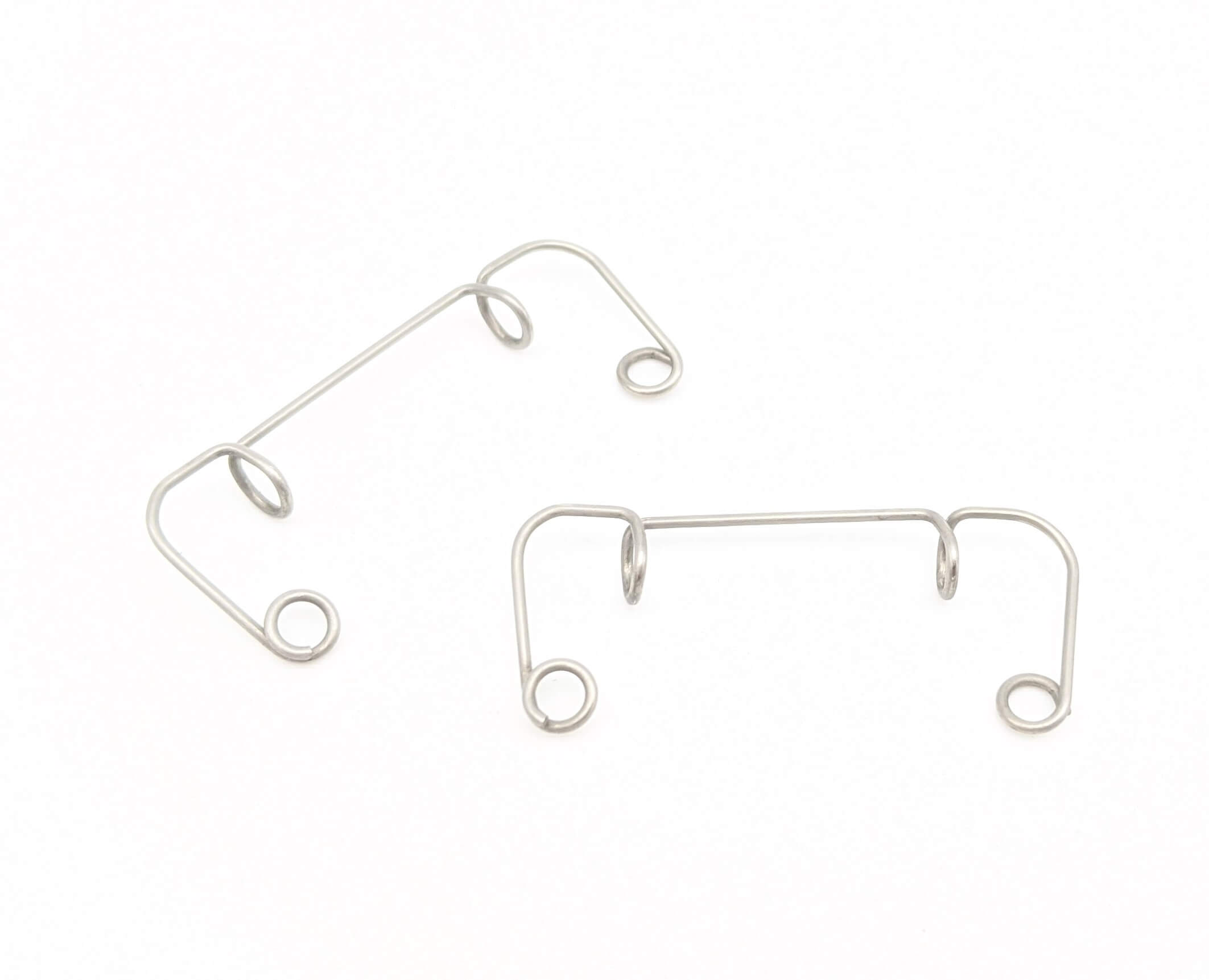

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Springs are essential components in many mechanical systems, from simple door hinges to complex automotive suspensions. Understanding the maximum compression a spring can withstand is crucial for ensuring safe and

Springs are essential components in many mechanical systems, from simple door hinges to complex automotive suspensions. Understanding the maximum compression a spring can withstand is crucial for ensuring safe and reliable operation. This article will delve into the factors that influence maximum spring compression, providing practical guidance for engineers and enthusiasts seeking to maximize spring performance.

Spring compression refers to the amount of deformation a spring experiences when a force is applied to it. It's essential to determine the maximum compression a spring can handle without permanent deformation or failure.

Several factors determine the maximum compression a spring can withstand. These include:

The material used to make a spring plays a significant role in its compression capabilities. Spring steel, a common material, offers excellent strength and elasticity. Other materials like phosphor bronze and titanium are used for corrosion resistance and high-temperature applications. The material's elastic limit, a measure of its ability to return to its original shape after deformation, is crucial.

A thicker wire diameter results in a stronger spring that can withstand higher compression forces. The wire diameter is directly related to the spring's stiffness, with thicker wires producing stiffer springs.

The diameter of the coils in a helical spring influences its compression. A smaller coil diameter leads to a tighter spring with higher compression capabilities. However, it's important to consider the potential for coil-to-coil contact at high compression levels.

The free length of the spring, its length when unloaded, determines the maximum compression it can experience. A longer free length allows for greater compression before reaching the solid height, the point where the coils come into contact.

Spring rate, also known as spring constant, reflects the stiffness of the spring. A higher spring rate means the spring exerts a greater force for a given compression. Higher spring rates generally translate to lower maximum compression, as the spring reaches its solid height sooner.

Determining the maximum spring compression involves a combination of theoretical calculations and practical considerations. Here's a simplified approach:

The following formula provides an approximate maximum compression based on the spring's free length and solid height:

Maximum Compression = Free Length - Solid Height

The solid height is the length of the spring when the coils are fully compressed against each other. It's important to note that this calculation represents a theoretical maximum. In practice, other factors can influence actual compression.

In real-world applications, factors like material fatigue, manufacturing tolerances, and operating conditions can affect the actual maximum compression. It's best to consult with a spring manufacturer or engineer for accurate calculations and recommendations.

When designing or selecting springs, it's crucial to consider safety factors. Always design springs with a sufficient safety margin to ensure they don't exceed their maximum compression capabilities under normal operating conditions. Factors like shock loading, temperature variations, and corrosion need to be considered.

To maximize the compression capabilities of a spring while maintaining safety, you can explore these options:

Choosing a spring material with a high elastic limit and excellent fatigue resistance can significantly increase the maximum compression. Consult material data sheets and consider the application's specific requirements.

Increasing the wire diameter can enhance the spring's strength and compression resistance. However, thicker wires can lead to increased spring stiffness and potentially affect other aspects of the design.

Reducing the coil diameter can increase the spring's compression capabilities. However, excessive reduction can lead to coil-to-coil contact and potential failure.

A longer free length allows for greater compression before reaching the solid height. However, excessive free length might compromise the spring's overall size and functionality.

Lowering the spring rate can allow for higher compression before reaching the solid height. However, this might affect the spring's ability to provide the desired force.

Understanding and managing maximum spring compression is crucial for the successful and safe operation of mechanical systems. By carefully considering the factors discussed, conducting appropriate calculations, and incorporating safety factors, engineers and enthusiasts can optimize spring performance and ensure reliable operation.

Remember, the maximum spring compression is not just a theoretical concept. Real-world applications demand practical considerations and safety margins. Consulting with experts, performing thorough calculations, and incorporating safety factors are all essential steps in maximizing spring compression while maintaining reliability and safety.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.