Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Hom dpot compression springs, often overlooked in the grand scheme of industrial components, are unsung heroes of engineering. These seemingly simple coiled wonders are the backbone of countless machines and

Hom dpot compression springs, often overlooked in the grand scheme of industrial components, are unsung heroes of engineering. These seemingly simple coiled wonders are the backbone of countless machines and systems, quietly ensuring smooth operation and unwavering performance. Their ability to withstand immense forces and return to their original shape makes them invaluable for applications ranging from automotive suspension systems to delicate medical devices. This article delves into the fascinating world of hom dpot compression springs, exploring their unique characteristics, diverse applications, and the crucial role they play in shaping the world around us.

Hom dpot compression springs are a type of helical spring designed to absorb and store energy when compressed. Unlike their counterparts, tension springs, which extend under load, compression springs shorten when subjected to force. This seemingly simple distinction sets them apart, enabling them to serve a wide range of functions in various industries.

These springs are typically crafted from high-quality spring steel, a material chosen for its remarkable elasticity and strength. The process of crafting these springs involves winding a wire around a cylindrical core, resulting in a coil that seamlessly compresses and expands, exhibiting remarkable resilience.

Hom dpot compression springs are renowned for their ability to withstand significant compression forces without permanent deformation. This remarkable characteristic makes them ideal for applications where substantial load-bearing capacity is paramount. For instance, in automotive suspension systems, they play a critical role in absorbing bumps and shocks, ensuring a smooth ride.

Hom dpot compression springs come in a multitude of configurations, each designed to address specific requirements. The diameter of the wire used, the number of coils, the spring index (the ratio of coil diameter to wire diameter), and the spring rate (the force required to compress the spring by a specific distance) are key factors that determine the overall performance of these springs.

When choosing a hom dpot compression spring for a particular application, it is imperative to consider the load it will bear, the amount of compression required, and the necessary spring rate. These springs can be designed to operate within a specific range of compression, ensuring optimal performance and a long lifespan.

Hom dpot compression springs find a wide range of applications across diverse industries, including:

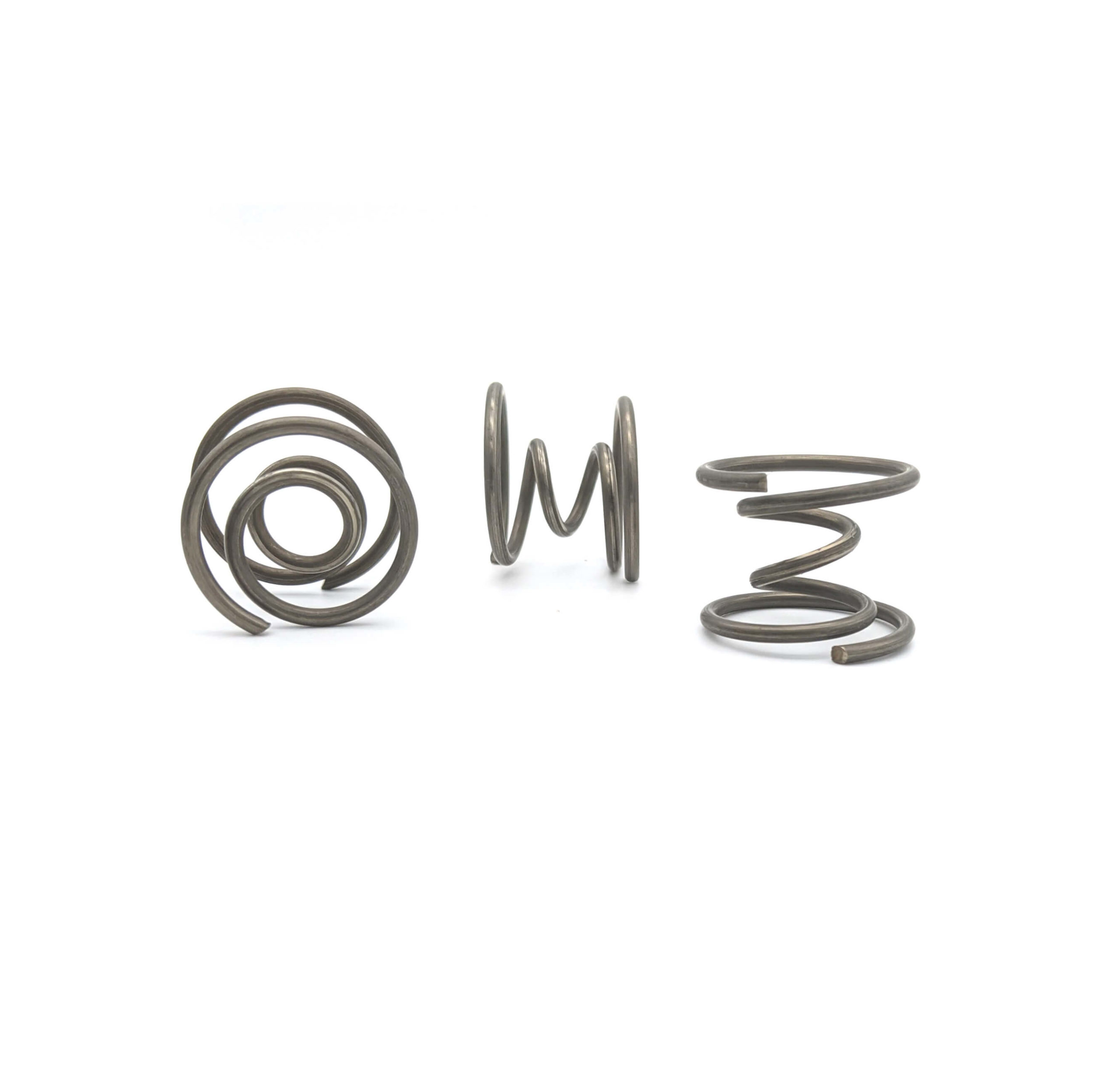

While the standard hom dpot compression spring is ubiquitous, several specialized variations are designed to address unique challenges and enhance performance. These include:

Selecting the appropriate hom dpot compression spring is paramount to ensuring the successful and reliable performance of any system. Failure to choose the right spring can lead to premature wear, fatigue, or even failure, potentially resulting in damage or injury.

Factors such as load, compression, and the required spring rate must be carefully considered during the selection process. It is always advisable to consult with a qualified engineer or spring specialist to ensure the chosen spring is the optimal solution for the application.

Hom dpot compression springs are more than just mechanical components; they are the backbone of countless technologies and innovations that shape our world. From the simple act of opening a door to the complex operation of a spacecraft, these springs silently contribute to the smooth functioning of our daily lives. Their unwavering reliability, versatility, and ability to withstand immense forces make them essential for ensuring the performance and longevity of countless machines, systems, and devices.

As technology continues to advance, hom dpot compression springs will continue to evolve, becoming even more sophisticated and capable of meeting the demanding requirements of future engineering challenges. The legacy of these springs will endure, as they remain the silent powerhouses driving innovation and progress across various fields.

Hom dpot compression springs are an embodiment of simple yet elegant design, proving that even the most seemingly mundane components can play a pivotal role in shaping the world around us. From automotive suspension systems to medical devices, these springs consistently deliver exceptional performance, ensuring reliability, efficiency, and innovation in countless applications. Their enduring legacy is a testament to their crucial role in advancing technology and shaping our world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.