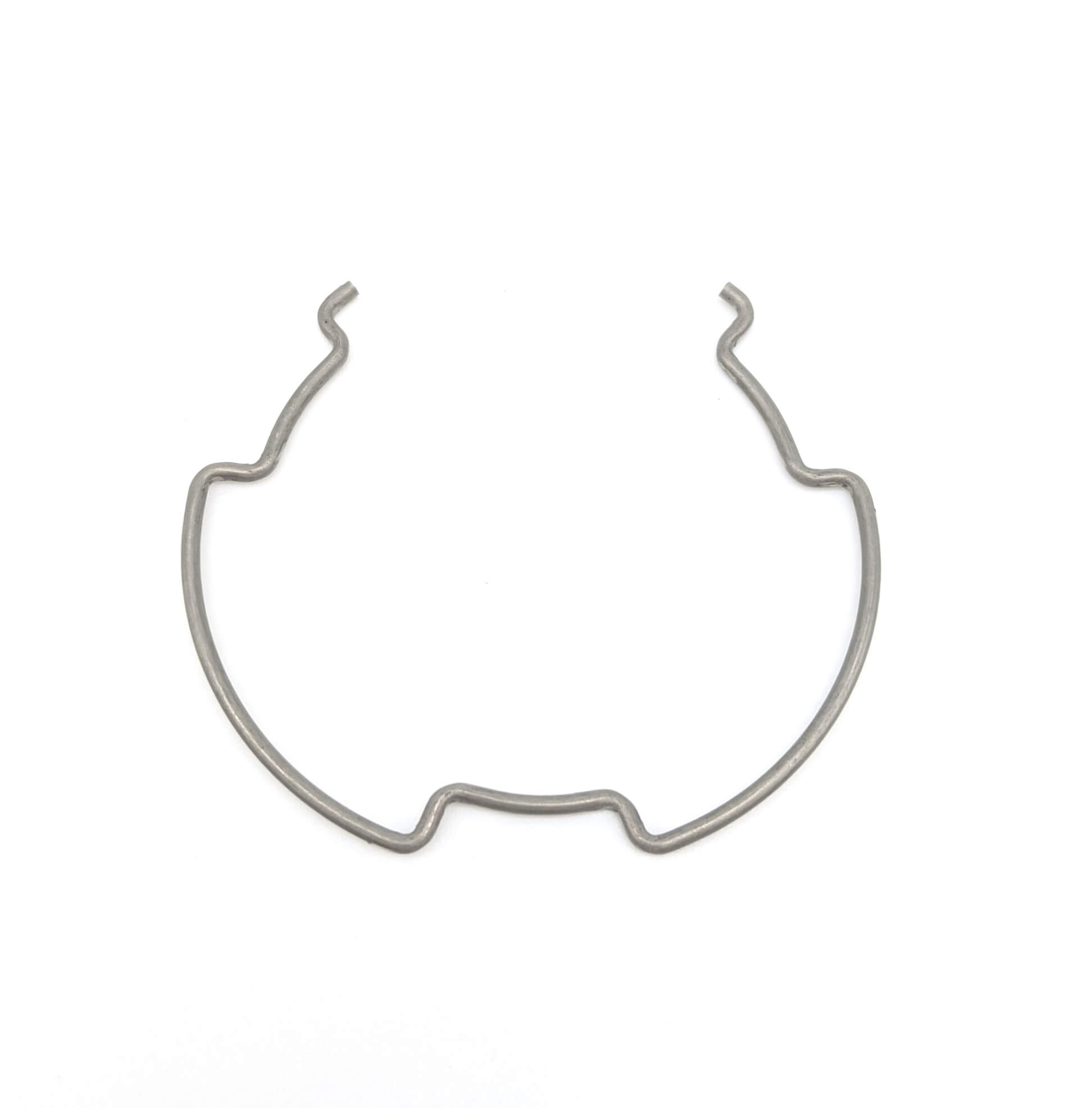

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Hom Dpot compression springs are a crucial component in numerous mechanical systems, offering resilience and force to various applications. These springs are designed to absorb and release energy, providing essential

Hom Dpot compression springs are a crucial component in numerous mechanical systems, offering resilience and force to various applications. These springs are designed to absorb and release energy, providing essential functionality to diverse industries. This article delves into the world of hom dpot compression springs, exploring their characteristics, types, applications, and the factors to consider when selecting the right spring for your needs. Whether you're an engineer, designer, or simply curious about the mechanics behind these ubiquitous components, this guide will provide a comprehensive overview of the fascinating realm of hom dpot compression springs.

Hom dpot compression springs are helical springs designed to resist compression forces. They are typically made from high-quality steel, although other materials like stainless steel, brass, and phosphor bronze are used for specific applications. These springs work by converting potential energy into mechanical energy, storing energy when compressed and releasing it when allowed to expand.

Hom dpot compression springs come in various configurations, each with specific properties and applications. Some common types include:

Hom dpot compression springs are indispensable components in numerous applications, including:

Selecting the right hom dpot compression spring for your application is crucial for optimal performance and reliability. Here are some key factors to consider:

Hom dpot compression springs offer several benefits, making them a preferred choice in various applications:

To ensure the proper function and longevity of hom dpot compression springs, it's essential to consider the following:

Hom dpot compression springs are ubiquitous components found in numerous mechanical systems. Their ability to store and release energy, providing essential functionality, makes them indispensable across diverse industries. By understanding the characteristics, types, applications, and factors to consider when selecting hom dpot compression springs, engineers and designers can ensure optimal performance and reliability in their projects. As technology continues to advance, the demand for these springs will likely grow, making them a vital component in the development of innovative solutions for various applications.

In conclusion, hom dpot compression springs are essential components in a wide array of mechanical systems, providing resilience, durability, and versatility. Their ability to store and release energy makes them vital for various applications, from automotive and aerospace to medical devices and industrial machinery. By carefully selecting the right spring for the specific requirements of a project, engineers and designers can ensure optimal performance and longevity, contributing to the development of innovative and reliable solutions across diverse fields.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.