Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

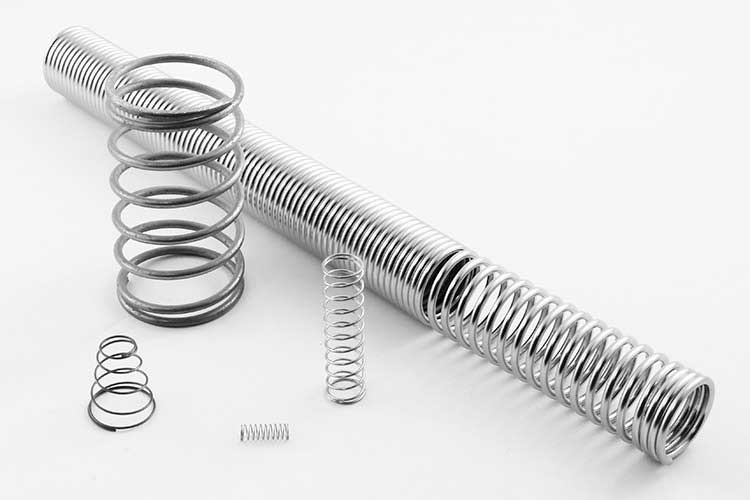

Helical compression springs, often simply referred to as coil springs, are ubiquitous components in countless mechanical systems. From the simple act of opening a door to the complex workings of

Helical compression springs, often simply referred to as coil springs, are ubiquitous components in countless mechanical systems. From the simple act of opening a door to the complex workings of automotive suspensions, these springs are the unsung heroes, silently performing their duty of storing and releasing energy. This article delves into the world of helical compression springs, exploring their design, material selection, applications, and the fundamental principles governing their behavior.

Helical compression springs, as the name suggests, are coiled springs designed to resist compression. They consist of a wire wound in a helical shape, typically around a cylindrical core. When a force is applied to the spring, it compresses, storing potential energy. Upon removal of the force, the spring returns to its original shape, releasing the stored energy. The amount of force required to compress the spring, its spring rate, is a crucial characteristic that dictates its suitability for a particular application.

The material chosen for a helical compression spring is paramount in determining its performance and longevity. Spring steel, renowned for its elasticity and resilience, is the most widely used material. However, other materials like stainless steel, phosphor bronze, and titanium are employed when corrosion resistance or specific electrical properties are required.

Spring steel is further classified based on its carbon content and heat treatment. High-carbon steel offers greater strength and hardness, while lower-carbon steels provide better ductility. The choice of steel grade depends on the desired balance of strength, stiffness, and fatigue resistance.

The design of a helical compression spring involves several crucial parameters that dictate its performance:

These parameters are carefully chosen based on the specific application's requirements for spring rate, load capacity, and operating environment.

Helical compression springs are found in a vast array of applications, from everyday objects to sophisticated machinery. Some prominent examples include:

This is merely a glimpse into the diverse applications of these versatile components.

Helical compression springs offer several advantages that make them highly desirable in many applications:

Helical compression springs are essential components in countless mechanical systems. Their ability to store and release energy, coupled with their versatility and reliability, makes them invaluable in diverse applications. Understanding their design parameters, material selection, and performance characteristics is crucial for engineers and designers to select the optimal spring for a particular application. As we continue to advance technologically, the role of these seemingly simple yet vital components will only grow in importance.

Helical compression springs are indeed workhorses, quietly and efficiently fulfilling their task in countless mechanical systems. Their importance is often overlooked, but their presence is undeniable. Their ability to store and release energy, coupled with their versatility and reliability, ensures they will continue to be integral components in our world for years to come.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.