Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

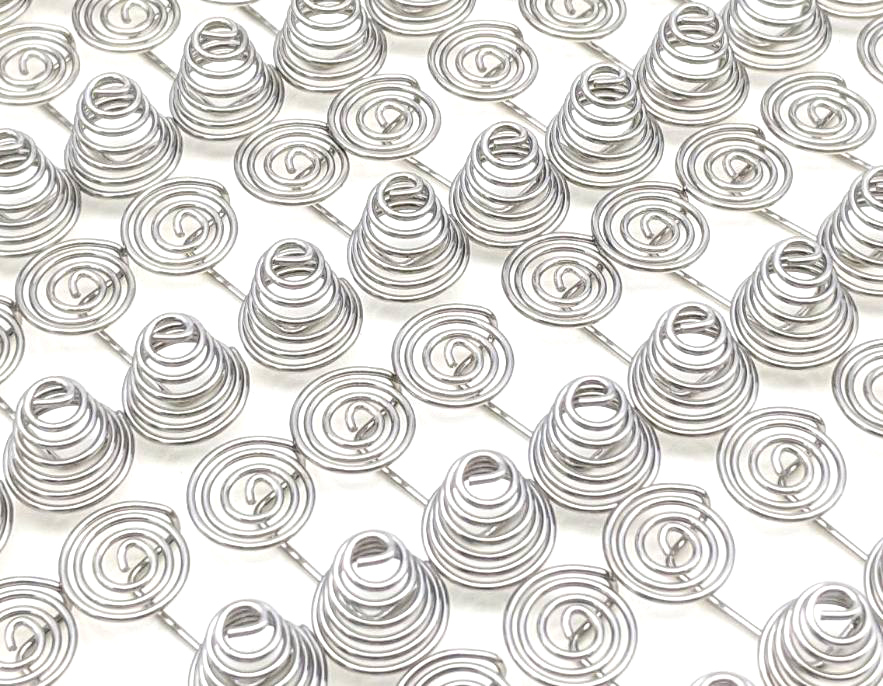

Helical compression springs, those ubiquitous coiled wonders of metal, are the unsung heroes of countless mechanical systems. From the simplest door hinges to the intricate workings of heavy machinery, these

Helical compression springs, those ubiquitous coiled wonders of metal, are the unsung heroes of countless mechanical systems. From the simplest door hinges to the intricate workings of heavy machinery, these springs play a vital role in ensuring smooth operation, absorbing shocks, and storing energy. Understanding their design, material properties, and applications is crucial for engineers and anyone seeking to design or maintain reliable mechanical systems. Let's dive into the fascinating world of helical compression springs and uncover their secrets.

Helical compression springs, as their name suggests, are springs that are wound in a helical shape, resembling a coil. When a force is applied to compress the spring, it stores potential energy, and when the force is released, the spring pushes back to its original length. This simple yet powerful principle has led to their wide-spread use in various applications.

To fully appreciate the utility of helical compression springs, we need to understand their key characteristics:

The spring rate, often referred to as the spring constant, is a crucial parameter that determines how much a spring compresses under a given force. It's represented by the letter 'k' and measured in units of force per unit of distance (e.g., N/mm or lbf/in). A high spring rate indicates a stiff spring, requiring more force to compress, while a low spring rate indicates a softer spring that compresses easily.

The diameter of the wire used to form the helical coil is a fundamental factor in determining the spring's strength and resilience. Thicker wires create stronger springs capable of handling higher loads. The choice of material also plays a vital role. Spring steel, renowned for its high elasticity and strength, is the most common material. Other materials, such as phosphor bronze or titanium, might be chosen for specific applications requiring corrosion resistance or high-temperature performance.

The free length of the spring is its total length when it's not under any load. The solid height is the length of the spring when it's fully compressed, with all the coils touching. These dimensions are crucial for determining the spring's operating range and ensuring it functions properly within the constraints of the application.

The ends of the helical compression spring are often designed with specific shapes to facilitate attachment and proper load distribution. Common end types include plain ends, ground ends, and closed and ground ends. The choice of end type depends on the specific requirements of the application.

Helical compression springs are truly versatile, finding their way into countless applications across various industries. Some notable examples include:

The design and manufacture of helical compression springs is a complex process that requires careful consideration of several factors:

Modern spring manufacturing employs advanced techniques like wire drawing, cold forming, and heat treatment to achieve precise tolerances and high-quality springs.

The popularity of helical compression springs stems from their numerous advantages:

Helical compression springs are essential components in a vast array of mechanical systems, contributing to their efficiency, safety, and performance. Their ability to store energy, absorb shocks, and provide restoring forces makes them invaluable in countless industries. As we delve deeper into the world of mechanics, we gain a newfound appreciation for the unassuming yet indispensable role of helical compression springs in our daily lives.

Whether you're a seasoned engineer or just starting to explore the world of mechanical systems, understanding helical compression springs is a valuable asset. From their basic principles to their diverse applications, these springs offer a compelling glimpse into the innovative world of engineering. By mastering their design, selection, and implementation, we can unlock the full potential of these remarkable mechanical components and build more resilient and efficient systems.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.