Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Heavy-duty coil springs, the unsung heroes of various industries, play a crucial role in providing essential support and resilience to countless applications. From heavy machinery to automotive vehicles, these robust

Heavy-duty coil springs, the unsung heroes of various industries, play a crucial role in providing essential support and resilience to countless applications. From heavy machinery to automotive vehicles, these robust components withstand immense forces, ensuring smooth operation and longevity. This article delves into the fascinating world of heavy-duty coil springs, exploring their construction, types, applications, and the factors that contribute to their impressive durability.

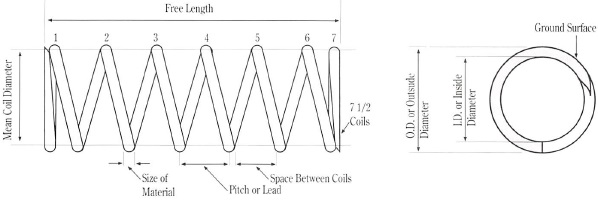

Heavy-duty coil springs, as the name suggests, are designed to handle hefty loads and operate in demanding environments. Their construction is a testament to their strength, featuring high-quality materials and meticulous engineering. The core of a coil spring is typically made from high-carbon steel, known for its exceptional tensile strength and resistance to fatigue. This robust material is then heat-treated to enhance its hardness and durability, ensuring that the spring can withstand repeated cycles of compression and extension.

The coil itself is meticulously wound, with each loop meticulously spaced to optimize the spring's performance. This precise winding process ensures that the spring can absorb and release energy efficiently, preventing unwanted vibrations and maintaining a smooth operation. The ends of the coil are then carefully formed to create a secure attachment point, allowing the spring to be easily integrated into various systems.

Heavy-duty coil springs are available in a wide array of types, each designed to meet the specific demands of its intended application. The most common types include:

The choice of spring type depends on the specific application and the nature of the forces involved. A thorough understanding of the operating conditions and the required performance characteristics is crucial for selecting the right type of heavy-duty coil spring.

The exceptional strength and durability of heavy-duty coil springs make them indispensable components in a wide range of industries. Here are some notable applications:

The applications of heavy-duty coil springs continue to evolve as technology advances and new industries emerge. Their ability to handle extreme loads and provide reliable performance makes them essential components in the modern world.

The durability of heavy-duty coil springs is influenced by several factors, including:

By understanding these factors, manufacturers and users can take steps to maximize the durability of heavy-duty coil springs and ensure their long-term reliability.

While heavy-duty coil springs are designed to withstand demanding conditions, proper maintenance is essential for ensuring their long-term performance. Regular inspections for signs of wear and tear, such as cracks, rust, or deformation, are crucial for identifying potential issues before they lead to failure. Proper lubrication can help prevent corrosion and reduce friction, further extending the lifespan of the spring.

In situations where heavy-duty coil springs are subjected to extreme loads or demanding environments, it's advisable to consider professional maintenance and repair services. Experienced technicians can assess the condition of the springs, identify any potential problems, and implement appropriate solutions to ensure continued operation.

In conclusion, heavy-duty coil springs are truly unsung heroes, quietly working behind the scenes to provide essential support and resilience to countless applications. Their strength, durability, and versatility make them indispensable components in a wide range of industries. From automotive vehicles to heavy machinery, these robust components play a vital role in ensuring the smooth operation and longevity of our modern world. By understanding their construction, applications, and maintenance requirements, we can appreciate the vital role that heavy-duty coil springs play in our daily lives.

The next time you encounter a heavy-duty coil spring, take a moment to appreciate its remarkable strength and durability. These seemingly simple components are a testament to human ingenuity, playing a crucial role in shaping the modern world around us.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.