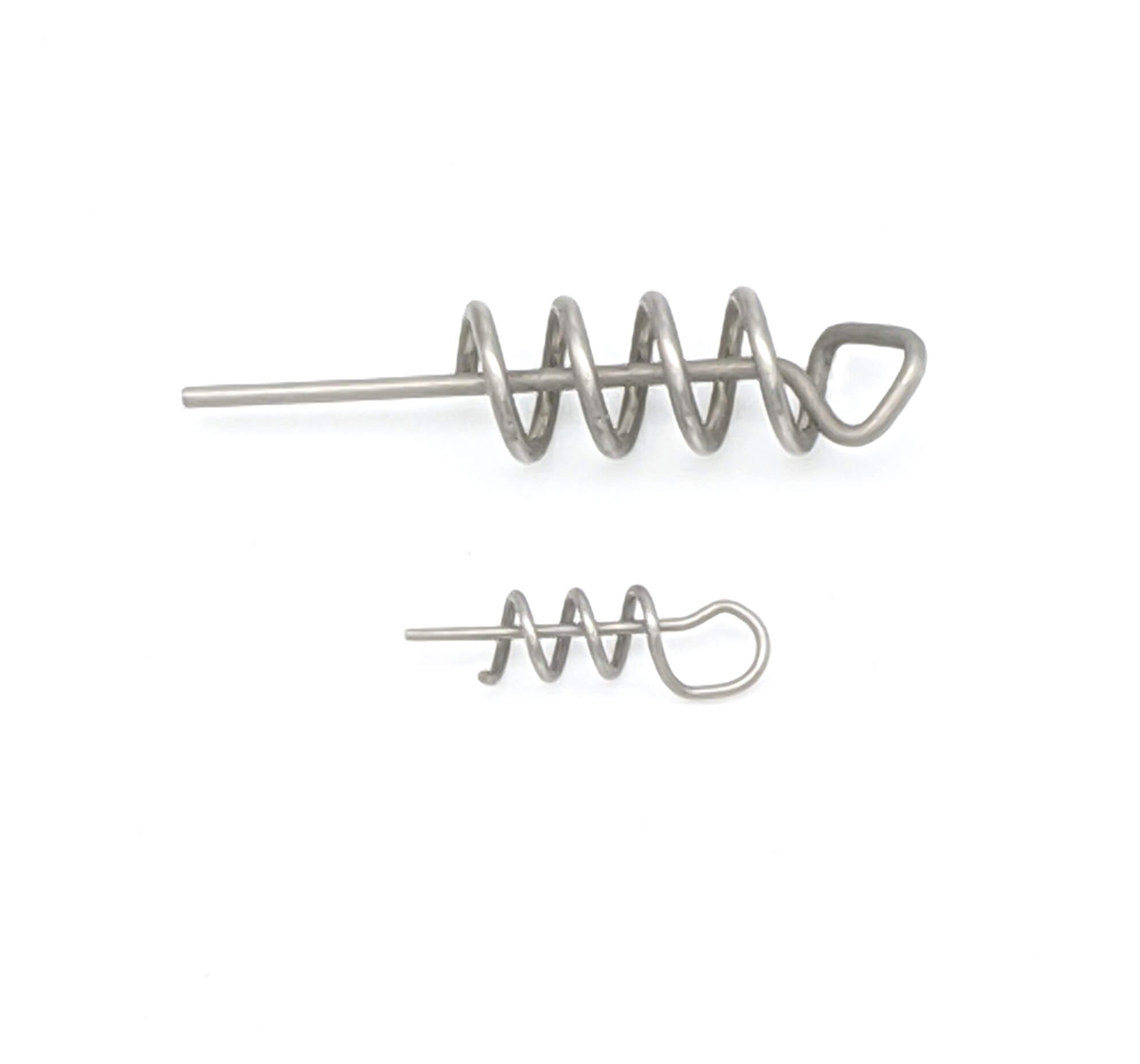

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Heavy duty tension springs are often overlooked, but these resilient components are the unsung heroes of strength and stability in countless applications. Whether holding a door securely closed, providing tension

Heavy duty tension springs are often overlooked, but these resilient components are the unsung heroes of strength and stability in countless applications. Whether holding a door securely closed, providing tension for a suspension system, or powering a complex mechanical device, heavy duty tension springs are essential for reliable and efficient operation. Their ability to withstand immense forces, maintain their shape under stress, and provide consistent tension makes them indispensable in industries ranging from automotive and aerospace to manufacturing and construction. In this article, we'll delve into the world of heavy duty tension springs, exploring their unique characteristics, diverse applications, and the crucial role they play in ensuring the smooth and robust performance of various systems.

Heavy duty tension springs are designed to handle significant loads and resist stretching or deformation under extreme conditions. These springs are typically crafted from high-strength materials, such as hardened steel or specialized alloys, to ensure durability and resilience. Their construction features robust wire diameters and tightly wound coils, allowing them to absorb and store energy efficiently while maintaining their integrity.

Here are some key features that set heavy duty tension springs apart from their lighter counterparts:

Heavy duty tension springs are employed in a wide array of industries and applications, playing a vital role in ensuring functionality, safety, and performance. Here are just a few examples:

Choosing the right heavy duty tension spring for a particular application is crucial for optimal performance and longevity. Here are some key factors to consider:

Heavy duty tension springs are remarkable components that play a crucial role in countless applications. Their ability to withstand extreme forces, maintain their integrity under stress, and provide precise tension control makes them indispensable in various industries. By understanding the key features, diverse applications, and selection criteria, engineers and designers can harness the power of these springs to ensure the smooth, reliable, and robust performance of their systems.

As you explore the world of engineering and mechanics, remember that heavy duty tension springs are often the silent, yet essential, components that hold systems together and enable them to function efficiently and safely. They are a testament to the enduring strength and reliability of well-designed mechanical solutions, and their role in driving innovation and progress across various fields is undeniable.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.