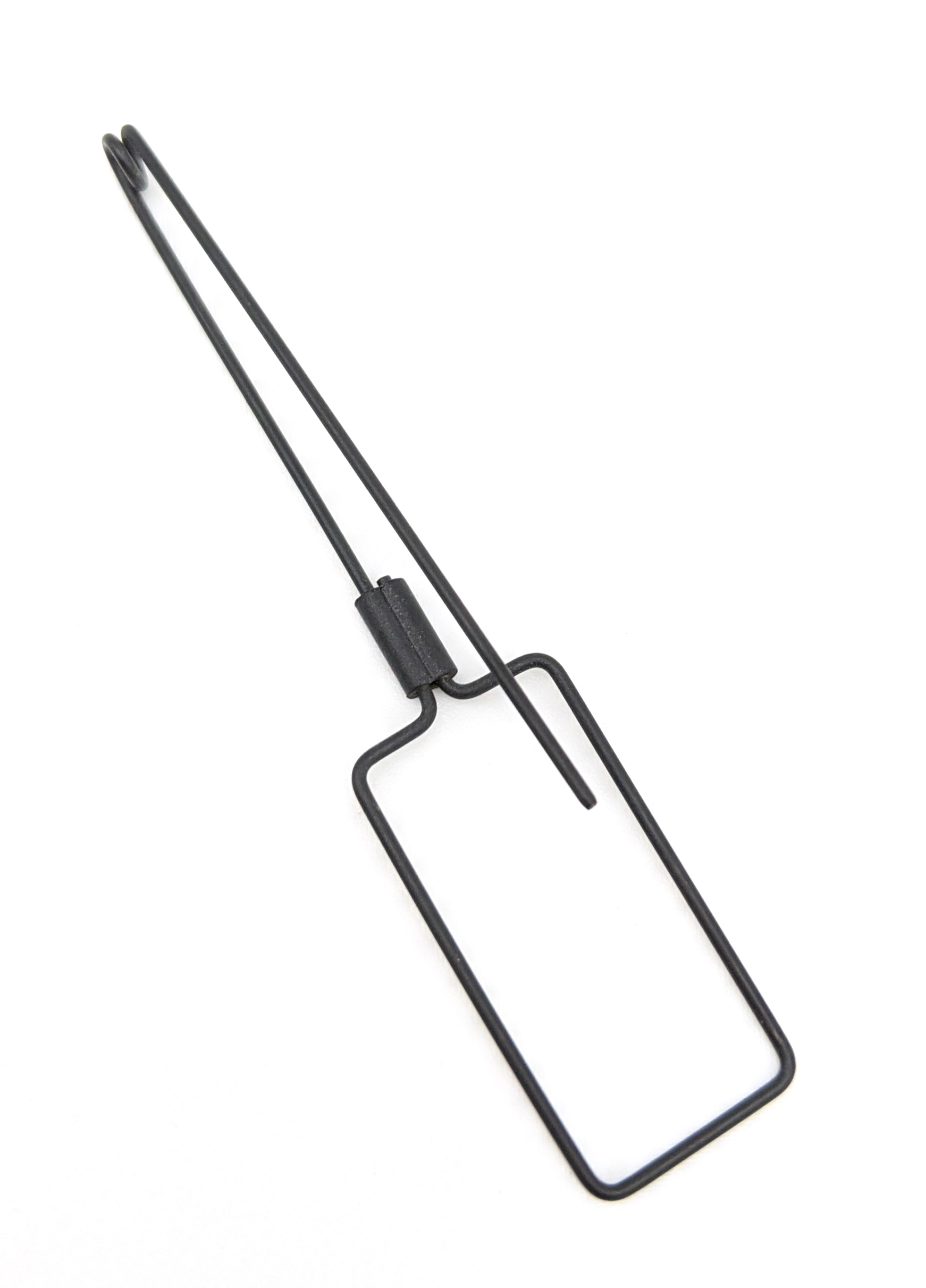

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

When you need a spring that can withstand extreme forces and maintain its integrity over countless cycles, heavy duty tension springs are the answer. These robust components are engineered for

When you need a spring that can withstand extreme forces and maintain its integrity over countless cycles, heavy duty tension springs are the answer. These robust components are engineered for demanding applications, offering a high level of resilience and dependability. From industrial machinery to automotive systems, heavy duty tension springs are the backbone of countless operations, ensuring smooth functionality and long-lasting performance.

Heavy duty tension springs are designed to operate under significant tension loads. They are crafted from high-quality materials, often steel alloys, and undergo rigorous manufacturing processes to ensure exceptional durability. These springs are engineered to stretch and retract repeatedly without losing their elasticity, making them ideal for demanding applications where reliability is paramount.

The versatility of heavy duty tension springs shines through in their diverse applications. They play a critical role in various industries, contributing to the smooth operation of machinery and systems. Let's delve into some of the key areas where these robust springs are indispensable.

In the realm of industrial machinery, heavy duty tension springs act as vital components, ensuring smooth operation and preventing malfunctions. They are used in:

Heavy duty tension springs are essential for the reliable operation of various automotive components. Their application in:

The use of heavy duty tension springs extends beyond industrial machinery and automotive systems. They are also found in:

Choosing the right heavy duty tension spring for your specific application requires careful consideration of several factors.

When it comes to heavy duty tension springs, quality is non-negotiable. Sourcing these springs from reputable manufacturers who adhere to rigorous quality control standards is essential to ensure reliability and longevity. Look for manufacturers with:

In addition to the standard features of heavy duty tension springs, there are several advanced options that can enhance their performance and suitability for specialized applications:

Proper maintenance is essential for extending the life of heavy duty tension springs. Regular inspection and lubrication can prevent premature wear and tear. If you notice any signs of damage, such as cracks, corrosion, or deformation, replace the spring immediately.

Heavy duty tension springs are crucial components in numerous applications, providing the strength, resilience, and dependability needed to withstand demanding conditions. By understanding their key features, applications, and factors to consider when selecting the right spring, you can ensure optimal performance and longevity for your systems. Remember, investing in high-quality springs from reputable manufacturers can make a significant difference in the overall reliability and success of your projects.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.