Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of industrial machinery, where heavy loads and demanding tasks are commonplace, heavy-duty compression springs are the silent workhorses that ensure smooth operation and reliable performance. These robust

In the world of industrial machinery, where heavy loads and demanding tasks are commonplace, heavy-duty compression springs are the silent workhorses that ensure smooth operation and reliable performance. These robust components play a crucial role in a wide range of applications, from automotive and aerospace to manufacturing and construction. Their ability to store and release energy, resist deformation, and withstand extreme forces makes them indispensable for maintaining efficiency and safety.

Compression springs, as their name suggests, are designed to absorb and store energy when compressed, providing a powerful counterforce against external forces. This fundamental principle makes them ideal for a multitude of applications where shock absorption, vibration damping, and controlled movement are critical. Heavy-duty compression springs, in particular, are built to handle the most demanding conditions, withstanding high loads, repeated cycles, and harsh environments.

Imagine a car suspension system. The compression springs play a vital role in absorbing the impact of bumps and potholes, ensuring a smooth and comfortable ride. Without them, every bump would send shockwaves through the car, causing discomfort and potential damage to the vehicle. Similarly, in industrial machinery, heavy-duty compression springs are used to dampen vibrations from motors, protect sensitive components, and ensure precise operation.

The construction of a heavy-duty compression spring is a testament to its impressive strength and durability. These springs are typically made from high-quality steel alloys, carefully chosen for their resistance to fatigue, corrosion, and wear. The process involves winding a wire of specific diameter and material around a mandrel, creating a coil with a defined pitch. The spring's load capacity and stiffness are determined by factors such as wire diameter, coil diameter, number of coils, and material properties.

A key characteristic of heavy-duty compression springs is their ability to withstand high stress and fatigue. Unlike their lighter counterparts, these springs are engineered with a larger wire diameter and a higher spring index (the ratio of coil diameter to wire diameter), ensuring exceptional resilience even under extreme loads. This robustness is essential for applications where frequent compression and release cycles are expected, such as in heavy machinery and construction equipment.

Heavy-duty compression springs are ubiquitous in a wide range of industries, playing a critical role in various applications. Let's take a closer look at some key areas where their strength and reliability are indispensable:

Automotive: From suspension systems to engine valve springs, heavy-duty compression springs are essential components in automobiles. They absorb shock loads, dampen vibrations, and ensure smooth operation of vital engine parts.

Aerospace: The demanding conditions of spaceflight require components that can withstand extreme temperatures, vibrations, and stresses. Heavy-duty compression springs are used in landing gear, actuators, and other critical systems, ensuring safe and reliable operation.

Manufacturing: In industrial machinery, heavy-duty compression springs are essential for a multitude of tasks. They power presses and stamping machines, control movement in robots and automated systems, and provide reliable force in material handling equipment.

Construction: From heavy-duty cranes and excavators to large-scale structural components, heavy-duty compression springs play a vital role in construction projects. They provide the necessary force for lifting, lowering, and stabilizing heavy loads, ensuring safety and efficiency.

Selecting the right heavy-duty compression spring for a specific application is a crucial step in ensuring its optimal performance and longevity. Several factors need to be considered, such as:

Load capacity: Determine the maximum force the spring needs to withstand during operation.

Spring rate: This indicates how much the spring will compress under a given load.

Fatigue resistance: Consider the number of compression cycles the spring will experience during its lifetime.

Environment: The operating environment will influence the choice of materials and coatings for the spring.

Space constraints: The dimensions of the spring must be compatible with the available space within the application.

Heavy-duty compression springs may be inconspicuous components, often hidden within machines and structures. But their contribution to the overall performance and reliability of various applications cannot be overstated. They are the unsung heroes of industrial strength, quietly ensuring smooth operation and safety in demanding environments. As we continue to push the boundaries of technology and engineering, heavy-duty compression springs will remain an integral part of the intricate machinery that powers our world.

The next time you encounter a heavy-duty machine or piece of equipment, take a moment to appreciate the silent workhorses that make it possible. Heavy-duty compression springs are the unsung heroes of industrial strength, quietly ensuring efficiency, safety, and reliability in a multitude of applications. They may be small, but their impact is enormous, powering progress and innovation in a wide range of industries.

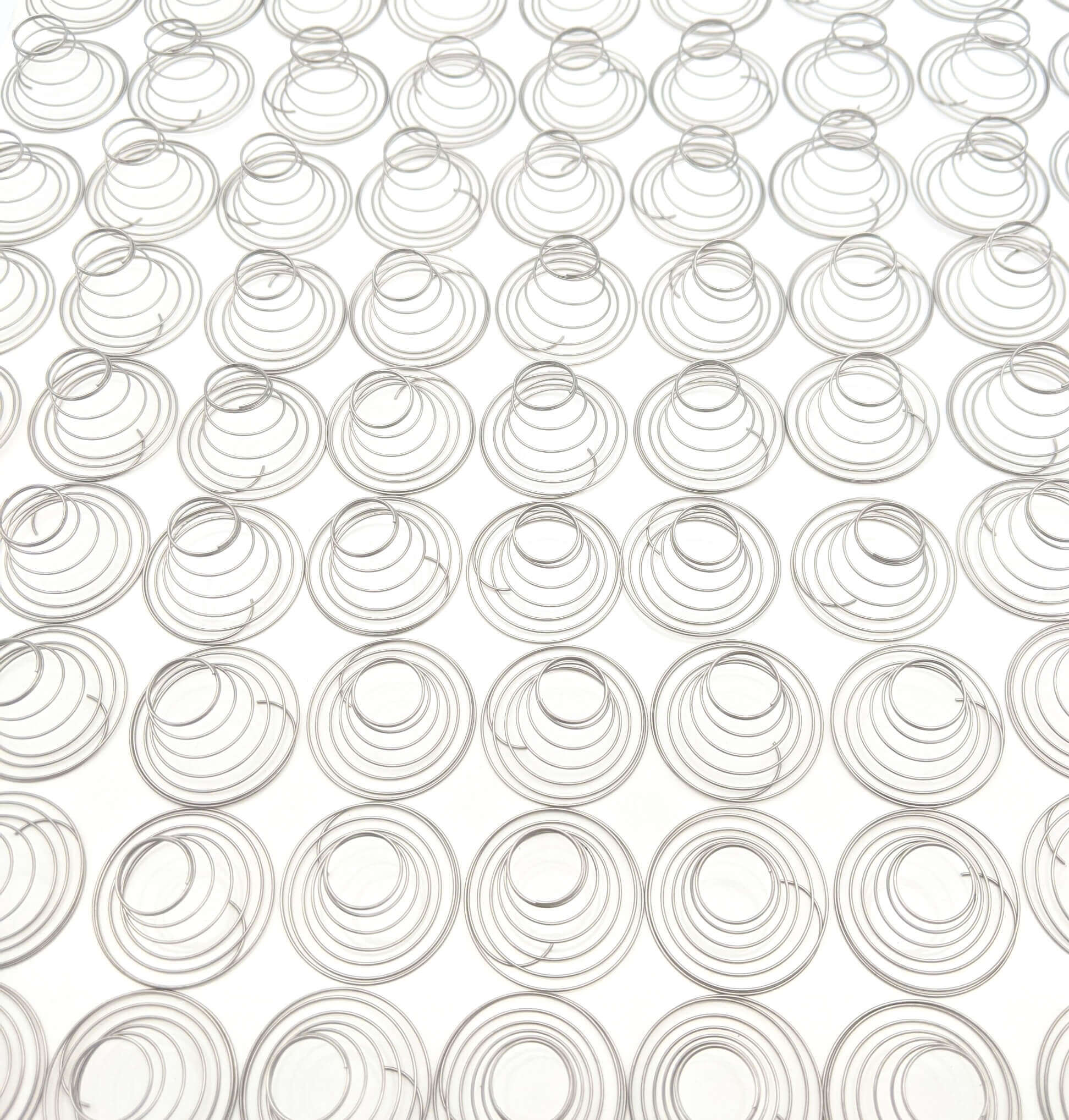

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.