Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of mechanical engineering, heavy duty compression springs are unsung heroes. These robust coiled wonders are often the backbone of complex systems, silently absorbing forces, storing energy, and

In the world of mechanical engineering, heavy duty compression springs are unsung heroes. These robust coiled wonders are often the backbone of complex systems, silently absorbing forces, storing energy, and ensuring smooth, reliable operation. From industrial machinery to everyday appliances, heavy duty compression springs are ubiquitous, playing a vital role in everything from lifting and clamping to shock absorption and tensioning. Their strength and resilience are essential for keeping machines running smoothly and ensuring the safety of those who operate them.

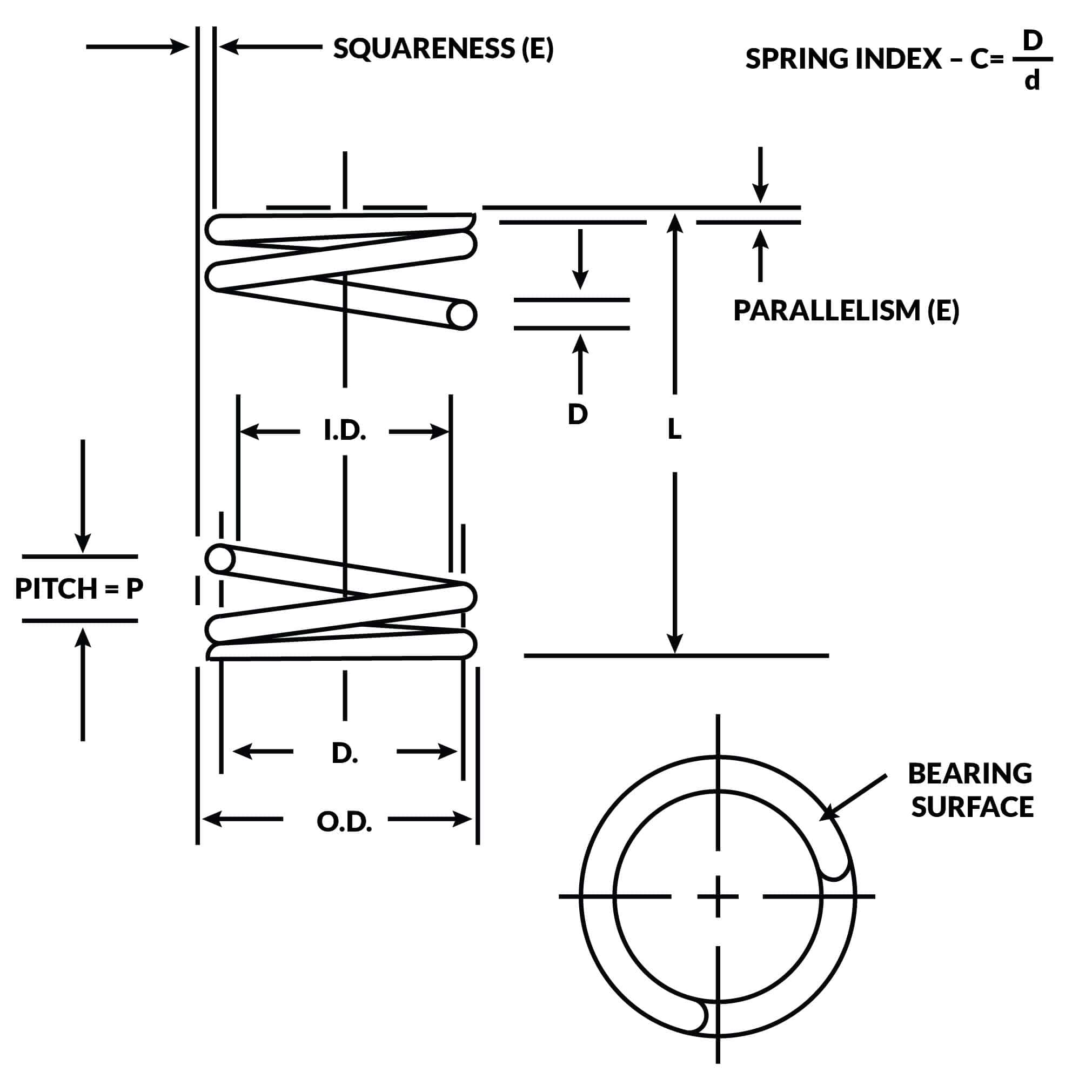

Heavy duty compression springs are specifically designed to withstand high loads and repeated cycles of compression. Unlike their lighter counterparts, these springs are built with thicker wire diameters and higher spring indices, enabling them to handle significant forces without deformation or failure. They are typically made from high-strength materials, such as hardened steel, ensuring long-term durability and reliability.

Heavy duty compression springs find applications in a wide range of industries, including:

Heavy duty compression springs offer a number of advantages over other types of springs:

When choosing a heavy duty compression spring for a specific application, several factors must be considered:

Heavy duty compression springs are essential components in countless applications, providing the strength, resilience, and reliability needed to ensure smooth operation. By understanding their characteristics and the factors involved in selecting the right spring for your needs, you can leverage their power to create robust and reliable systems.

Investing in quality heavy duty compression springs is investing in the long-term performance and safety of your systems. These springs are not just simple components; they are the backbone of strength and resilience that keep machines running smoothly and efficiently. So next time you encounter a heavy duty compression spring, take a moment to appreciate its hidden power and the role it plays in our modern world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.