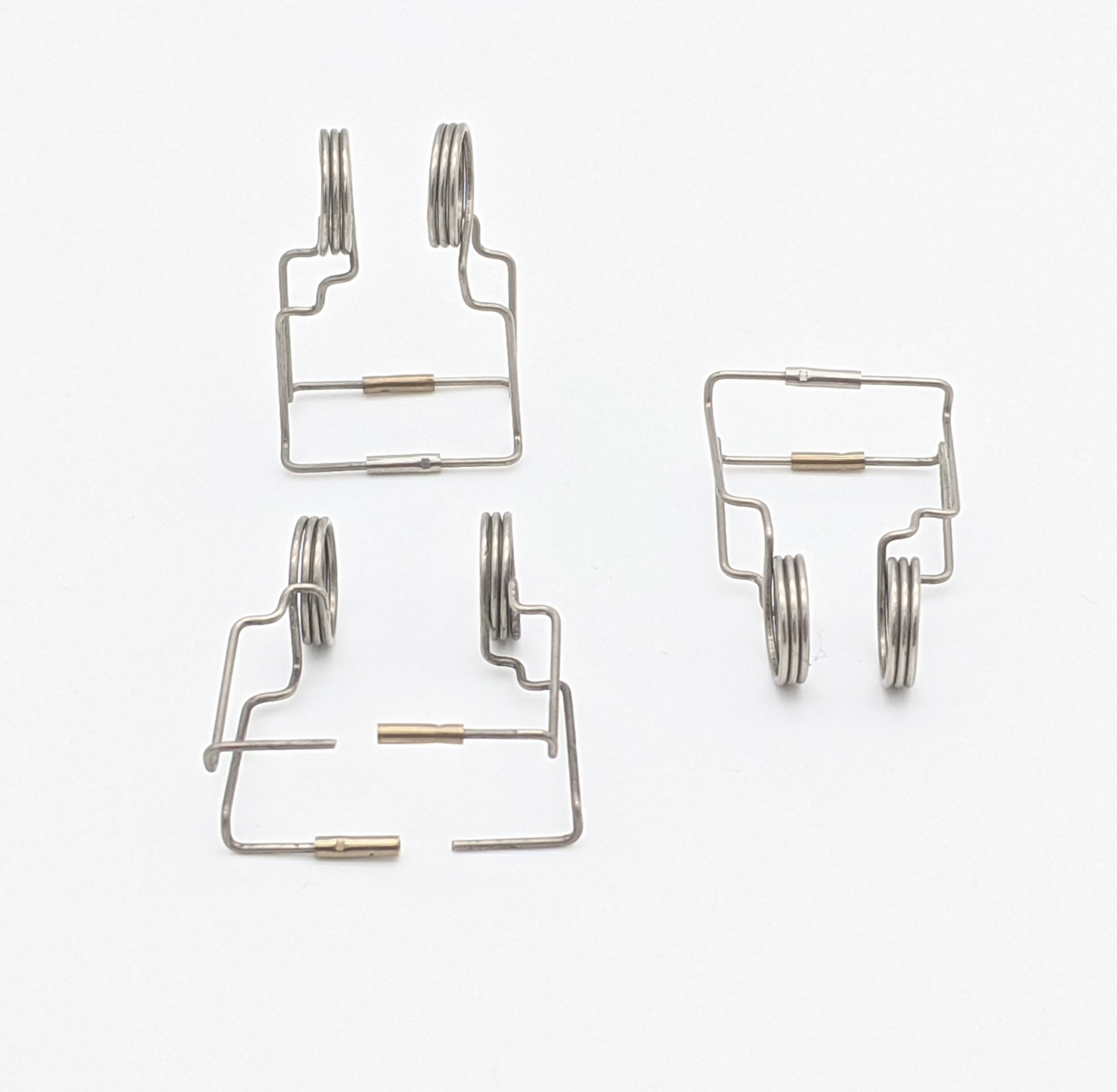

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Heavy duty compression springs are the unsung heroes of the industrial world. They are the sturdy, reliable components that power everything from machinery to vehicles to household appliances. These springs

Heavy duty compression springs are the unsung heroes of the industrial world. They are the sturdy, reliable components that power everything from machinery to vehicles to household appliances. These springs are designed to withstand immense forces and provide consistent, predictable performance under the most demanding conditions. Their strength, durability, and versatility make them essential for a wide range of applications, ensuring smooth operation and preventing failure in critical systems.

Heavy duty compression springs are a type of helical spring designed to resist compression forces. They are typically made from high-strength materials, such as steel or stainless steel, and are engineered to withstand significant loads without permanent deformation. These springs are characterized by their thick wire diameter, high coil density, and robust construction. The heavier duty the spring, the thicker the wire and the higher the coil density. The purpose is to achieve a strong spring that can withstand higher loads and provide longer service life.

Imagine a world without heavy duty compression springs. Your car's suspension system would collapse under the weight of the vehicle. The heavy machinery that powers industries would grind to a halt. The appliances you rely on every day would malfunction. Heavy duty compression springs are the silent workhorses that keep our world running smoothly. These springs are essential for a wide range of applications, including:

Heavy duty compression springs work by storing energy when compressed. When a force is applied to the spring, the coils compress. This compression stores potential energy within the spring, which is then released when the force is removed. The amount of force that a spring can withstand is determined by its wire diameter, coil density, and material. The higher the wire diameter, the greater the force it can withstand. Similarly, the higher the coil density, the more coils are compressed and the more force the spring can store. Finally, the material used to manufacture the spring plays a crucial role in its strength and performance. For heavy duty applications, high-strength steel or stainless steel are preferred due to their durability and resilience.

Choosing the right heavy duty compression spring for your application is essential for achieving optimal performance. There are a number of factors to consider, including:

Working with a reputable spring manufacturer can ensure that you select the right heavy duty compression spring for your application. A knowledgeable manufacturer will guide you through the selection process and ensure that the spring meets your specific needs.

There are a number of benefits to using heavy duty compression springs, including:

The future of heavy duty compression springs is bright. As industries continue to push the boundaries of innovation and performance, the demand for these robust components will only grow. New materials and manufacturing techniques are being developed to create even stronger, more reliable springs, making them a critical part of the technological advancements shaping our future.

Heavy duty compression springs are indispensable components in a wide range of industrial applications. Their ability to withstand immense forces and provide consistent performance make them the backbone of countless machines, vehicles, and systems. From the suspension systems of our cars to the machinery that powers our industries, heavy duty compression springs are the unsung heroes of modern engineering. Their strength, durability, and versatility ensure the smooth operation and reliability of critical systems, making them an essential part of our world.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.