Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the world of industrial machinery and heavy-duty applications, reliability and resilience are paramount. Heavy-duty coil springs, those robust and resilient components, play a crucial role in ensuring the smooth

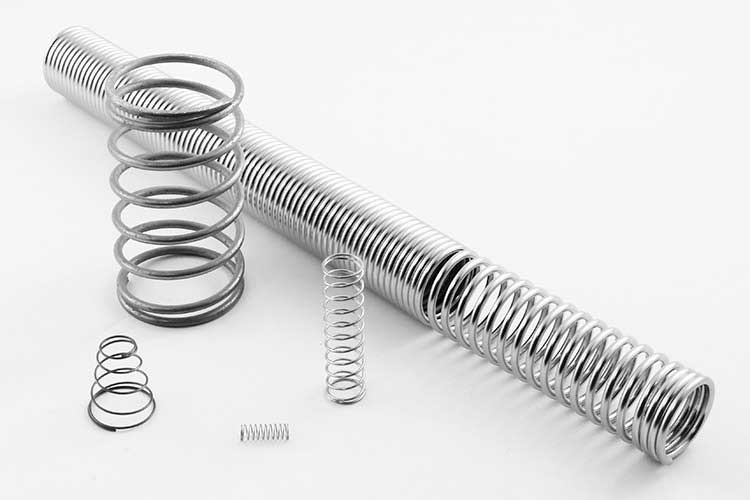

In the world of industrial machinery and heavy-duty applications, reliability and resilience are paramount. Heavy-duty coil springs, those robust and resilient components, play a crucial role in ensuring the smooth operation and longevity of equipment. From construction vehicles and mining operations to manufacturing lines and heavy-duty trucks, these springs are the unsung heroes of industrial strength, silently performing their duty under immense pressure and stress. Let's delve into the world of heavy-duty coil springs, exploring their unique characteristics, diverse applications, and the key factors that make them the backbone of industrial operations.

Heavy-duty coil springs are engineered marvels, specifically designed to withstand extreme forces and perform reliably under demanding conditions. Unlike their lighter counterparts, these springs are crafted from high-grade materials, often featuring thicker wire diameters and higher spring rates. This means they can absorb and release significant amounts of energy without losing their shape or functionality. Their robust construction allows them to handle large loads, endure continuous cycling, and maintain their structural integrity over extended periods.

The importance of heavy-duty coil springs in industrial applications cannot be overstated. They act as shock absorbers, dampening vibrations and protecting machinery from damage caused by sudden impacts. This is particularly critical in environments with heavy loads, such as mining and construction, where equipment is constantly subjected to harsh conditions. Moreover, these springs are often employed as tensioning devices, ensuring that moving parts remain in proper alignment and exert the required force, contributing to the smooth and efficient operation of complex machinery.

Several critical factors contribute to the exceptional performance of heavy-duty coil springs:

Heavy-duty coil springs are ubiquitous in numerous industries, playing vital roles in a wide range of applications:

Selecting the appropriate heavy-duty coil spring for a specific application is crucial to ensure optimal performance and longevity. Several factors must be considered when making this decision:

While heavy-duty coil springs are designed to withstand extreme conditions, proper maintenance is essential to ensure their longevity and optimal performance. Regular inspection for signs of wear, fatigue, and damage should be part of any routine maintenance program.

Heavy-duty coil springs are essential components in industrial operations, ensuring reliability, safety, and longevity of machinery. Their robust construction, high-grade materials, and specialized design enable them to handle extreme loads, absorb shocks, and perform consistently in demanding environments. By understanding the key features and considerations involved in choosing and maintaining these vital components, industries can maximize their operational efficiency and ensure a smooth and reliable workflow.

Heavy-duty coil springs are more than just pieces of metal; they are the backbone of industrial strength, silently contributing to the success of countless operations. Their performance directly impacts the safety, efficiency, and longevity of equipment, making them integral to the smooth functioning of any industry that relies on heavy machinery and demanding applications. By appreciating the crucial role of these springs and implementing proper selection, maintenance, and care, industries can maximize their value and continue to benefit from their unwavering resilience.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.