Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Working on vehicles, especially those with heavy-duty suspension systems, often involves dealing with stubborn coil springs. These springs, designed to withstand immense forces, can be quite challenging to compress for

Working on vehicles, especially those with heavy-duty suspension systems, often involves dealing with stubborn coil springs. These springs, designed to withstand immense forces, can be quite challenging to compress for repairs or maintenance. Enter the heavy-duty coil spring compressor, a powerful tool that empowers professionals to tackle these demanding tasks with ease and precision.

A heavy duty coil spring compressor is a specialized tool designed to safely and efficiently compress coil springs, particularly those found on trucks, SUVs, and other vehicles with robust suspension systems. These compressors are engineered to handle high spring forces, providing the leverage needed to overcome the resistance and compress the spring securely.

Using a heavy-duty coil spring compressor offers numerous advantages for mechanics and DIY enthusiasts working on vehicles with powerful coil springs:

Safety First: Coil springs store immense potential energy. Attempting to compress them manually or with inadequate tools is incredibly dangerous. A heavy-duty compressor provides a controlled and secure method, minimizing the risk of accidents.

Efficiency and Precision: These compressors allow you to precisely compress the spring, making it easier to remove and replace components like shocks, struts, or other suspension parts. This ensures proper installation and optimal performance.

Durability and Strength: Heavy-duty compressors are constructed from high-quality materials, capable of withstanding the immense forces exerted by the springs. They're built to last, providing reliable performance over time.

There are two primary types of heavy-duty coil spring compressors:

External Compressors: These compressors use a clamping mechanism to compress the spring from the outside. They're typically easier to use and often more affordable.

Internal Compressors: These compressors work by inserting a threaded rod or piston inside the spring. They offer greater precision and are often preferred for complex or delicate applications.

When selecting a heavy-duty coil spring compressor, consider the following factors:

Spring Capacity: Ensure the compressor can handle the spring's force rating, which is typically indicated by the manufacturer's specifications.

Vehicle Compatibility: Some compressors are designed specifically for certain vehicles or spring sizes. Check the compatibility before making a purchase.

Ease of Use: Opt for a compressor with a user-friendly design and intuitive operation. A robust clamping mechanism and clear markings can make the process smoother.

Safety Features: Look for safety features like a release mechanism that prevents accidental spring decompression.

Here are some essential safety tips when using a heavy-duty coil spring compressor:

Always use the correct tool for the job: Make sure the compressor is rated for the spring you are working with.

Secure the vehicle properly: Use jack stands or a sturdy lift to ensure the vehicle is securely supported. Never rely solely on a jack.

Follow the manufacturer's instructions: Carefully read and understand the instructions for your specific compressor.

Wear protective gear: Always wear safety glasses and gloves to protect yourself from potential hazards.

Never attempt to compress the spring manually: Use the compressor to compress the spring gradually and avoid sudden releases.

Be cautious when releasing the compression: Release the pressure slowly and in a controlled manner, paying close attention to your surroundings.

Regular maintenance ensures the longevity and safety of your heavy-duty coil spring compressor:

Inspect regularly: Check for any signs of wear or damage on the clamping mechanism, threaded rods, or other components.

Lubricate moving parts: Lubricate the moving parts to ensure smooth operation and reduce wear.

Store properly: Store the compressor in a clean and dry place to prevent corrosion and damage.

A heavy-duty coil spring compressor is a valuable tool for any mechanic or DIY enthusiast working on vehicles with powerful coil springs. It allows for safe, efficient, and precise compression, essential for repairs and maintenance tasks. By choosing the right compressor, understanding its operation, and adhering to safety guidelines, you can make the process smoother and minimize the risk of accidents. Remember, investing in a high-quality compressor and practicing proper techniques can help ensure a safer and more successful experience.

When working with heavy-duty coil springs, the right tools are crucial. A heavy-duty coil spring compressor is an indispensable asset for professionals and DIY enthusiasts alike. By prioritizing safety, understanding its usage, and maintaining the tool, you can confidently tackle these tasks with precision and efficiency.

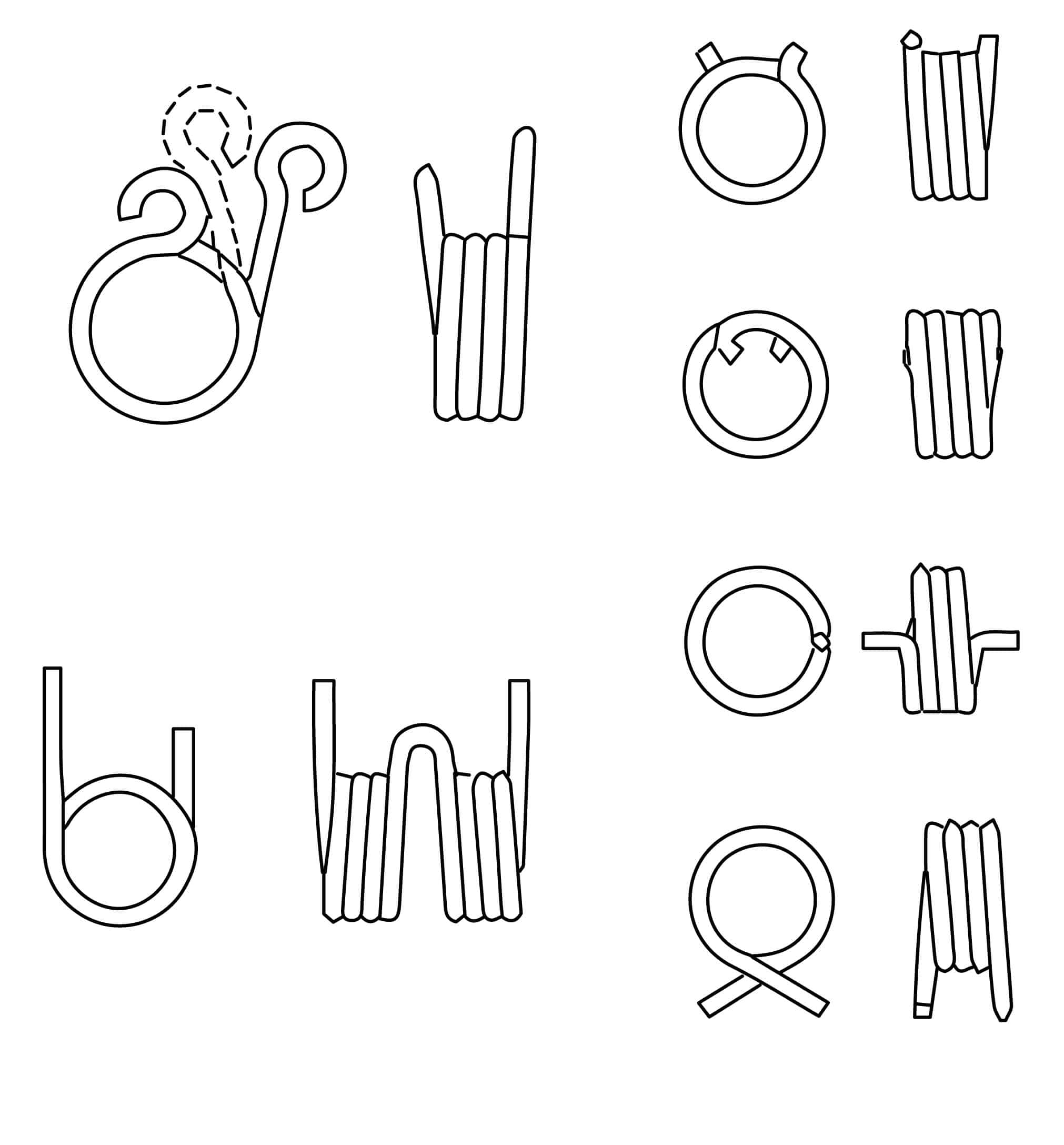

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.