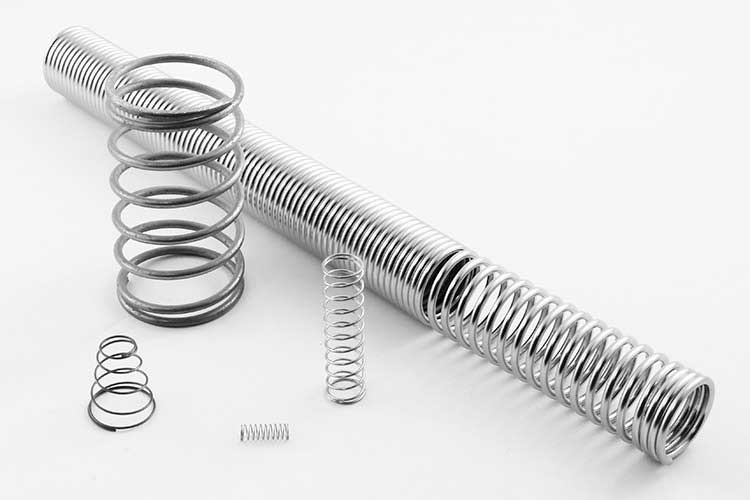

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Heavy-duty coil spring compressors are indispensable tools for mechanics and automotive enthusiasts tackling challenging spring compression tasks. These robust tools are designed to safely and efficiently compress heavy-duty springs found

Heavy-duty coil spring compressors are indispensable tools for mechanics and automotive enthusiasts tackling challenging spring compression tasks. These robust tools are designed to safely and efficiently compress heavy-duty springs found in trucks, SUVs, and other large vehicles, allowing for the removal and installation of components such as shocks, struts, and suspension systems. This comprehensive guide will delve into the intricacies of heavy-duty coil spring compressors, exploring their types, functionalities, safety precautions, and selection considerations.

Heavy-duty coil spring compressors are specialized tools engineered to handle the immense force exerted by large, heavy-duty springs. These springs are often found in trucks, SUVs, and other vehicles that require robust suspension systems to handle heavy loads. Unlike standard spring compressors designed for passenger cars, heavy-duty versions are built with enhanced strength and durability to withstand the higher compression forces involved.

The primary purpose of a heavy-duty coil spring compressor is to safely and effectively compress the spring, allowing for the removal or installation of related suspension components. These components can include shocks, struts, control arms, and other suspension parts that require access to the spring. Without a reliable spring compressor, working on these components can be incredibly dangerous, as the spring's sudden release can result in serious injuries.

Heavy-duty coil spring compressors come in various designs, each with its own set of advantages and disadvantages. Here are some of the most common types:

Working with heavy-duty coil spring compressors requires a high level of caution and safety awareness. Here are some critical safety considerations to keep in mind:

Choosing the right heavy-duty coil spring compressor is crucial for ensuring a safe and effective repair. Consider the following factors when selecting your compressor:

Heavy-duty coil spring compressors are essential tools for professionals and automotive enthusiasts working on trucks, SUVs, and other large vehicles. They allow for safe and efficient spring compression, enabling the removal and installation of suspension components. By understanding the different types, safety considerations, and selection factors, you can confidently choose the right compressor for your specific needs.

Remember, safety should always be your top priority when working with heavy-duty coil spring compressors. Never attempt to compress a spring without proper training and equipment. Always adhere to safety guidelines and never compromise on safety to save time or effort.

Investing in a high-quality heavy-duty coil spring compressor is an investment in safety and efficiency. With proper knowledge and careful application, you can safely and effectively tackle those challenging spring compression tasks, ensuring the longevity and performance of your vehicle's suspension system.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.