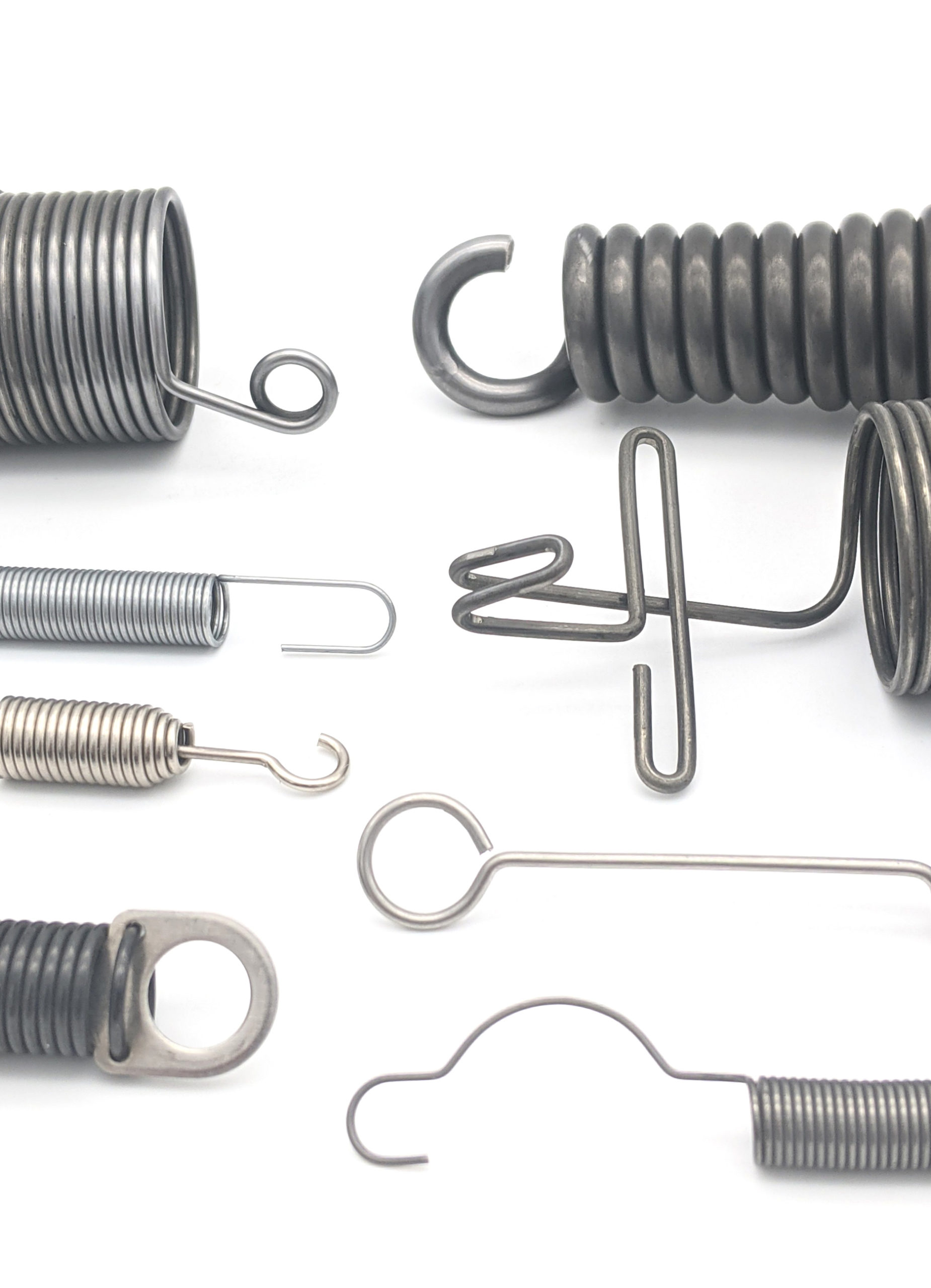

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Flat springs, often overlooked in the grand scheme of spring design, are anything but ordinary. These unassuming strips of spring steel, meticulously shaped and crafted, possess a remarkable versatility that

Flat springs, often overlooked in the grand scheme of spring design, are anything but ordinary. These unassuming strips of spring steel, meticulously shaped and crafted, possess a remarkable versatility that makes them essential components in a wide array of applications. From the delicate mechanisms of precision instruments to the robust demands of heavy machinery, flat springs silently contribute their strength and resilience, proving that sometimes the most straightforward solutions are the most effective.

Flat springs, as their name suggests, are springs crafted from flat pieces of spring steel. Their simplicity belies their impressive range of capabilities. Imagine a thin strip of metal, precisely shaped and tempered, ready to absorb energy and return to its original form. That, in essence, is the magic of a flat spring.

What makes flat springs so unique is their ability to flex and bend in multiple directions. Unlike their coiled counterparts, which primarily work in tension or compression, flat springs can handle a combination of forces, making them incredibly adaptable.

The performance of a flat spring hinges on its geometry and the material it's made from. A skilled engineer can manipulate the shape, thickness, and material of the spring to fine-tune its stiffness and deflection characteristics. This allows for precise control over how the spring behaves under load, ensuring it performs exactly as intended.

One of the key parameters that governs a flat spring's behavior is its spring rate. This refers to the amount of force required to deflect the spring a certain distance. A higher spring rate indicates a stiffer spring, resisting deformation more strongly.

The choice of spring steel is crucial. Different types of spring steel have varying levels of strength, hardness, and elasticity. Engineers carefully select the right steel to ensure the spring can withstand the required forces and stresses without compromising its performance or lifespan.

Flat springs have found their way into an astonishing array of applications, proving their versatility across industries. Let's explore a few key areas where these unassuming components shine:

In the realm of precision instruments, flat springs are often the unsung heroes. Their ability to provide precise, repeatable force and motion control makes them perfect for applications where accuracy is paramount.

Think of the delicate balance springs in watches, meticulously engineered to ensure the watch runs smoothly and accurately. Or consider the spring-loaded contacts in electrical switches, precisely calibrated to make and break connections with a minimum of wear and tear.

Flat springs are also used in various other precision devices, including:

The automotive industry has embraced flat springs for their durability and reliability. From the suspension systems of vehicles to the intricate mechanisms of transmissions, flat springs contribute to the smooth and efficient operation of automobiles.

Leaf springs, a classic example of flat springs, have long been used in vehicle suspension systems. These sturdy springs absorb the shocks and vibrations of the road, providing a comfortable ride for passengers.

Beyond suspension systems, flat springs can be found in various other automotive components:

Flat springs are indispensable in industrial and mechanical applications, where they provide robust solutions for a wide range of requirements.

From heavy-duty machinery to intricate assembly lines, flat springs can be found working tirelessly, ensuring smooth operation and preventing breakdowns.

Here are a few examples of their applications in this domain:

The process of manufacturing a flat spring begins with a meticulous design process. Engineers carefully consider the desired spring rate, load capacity, and deflection characteristics. This often involves using computer-aided design (CAD) software to simulate the spring's behavior under various conditions.

Once the design is finalized, the flat spring is typically produced using one of two methods:

In recent years, advancements in materials science and manufacturing technology have led to the development of new and innovative flat spring designs. These advanced designs often offer improved performance characteristics or cater to specific application requirements.

One notable example is the use of composite materials, which combine the strength and stiffness of metals with the flexibility and lightweight of polymers. This allows for the creation of flat springs that are lighter, stronger, and more resistant to fatigue.

Another development is the use of micro-spring technology. Micro-springs are incredibly small flat springs, often produced using micro-machining techniques. These miniature springs find applications in micro-electromechanical systems (MEMS) and other devices where size and precision are critical.

The humble flat spring stands as a testament to the power of simple, elegant design. Despite their apparent simplicity, these unassuming components play a crucial role in a wide range of applications, enabling precision, efficiency, and reliability in countless devices and systems.

As technology continues to evolve, flat springs will undoubtedly continue to play a vital role, adapting to new demands and pushing the boundaries of engineering innovation. So, next time you encounter a device or system incorporating a flat spring, take a moment to appreciate the quiet strength and versatility of this remarkable component.

Flat springs are a testament to the effectiveness of simplicity in engineering. They are versatile, reliable, and essential components in a diverse range of applications. From precision instruments to heavy machinery, flat springs silently contribute to the smooth and efficient operation of the world around us.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.