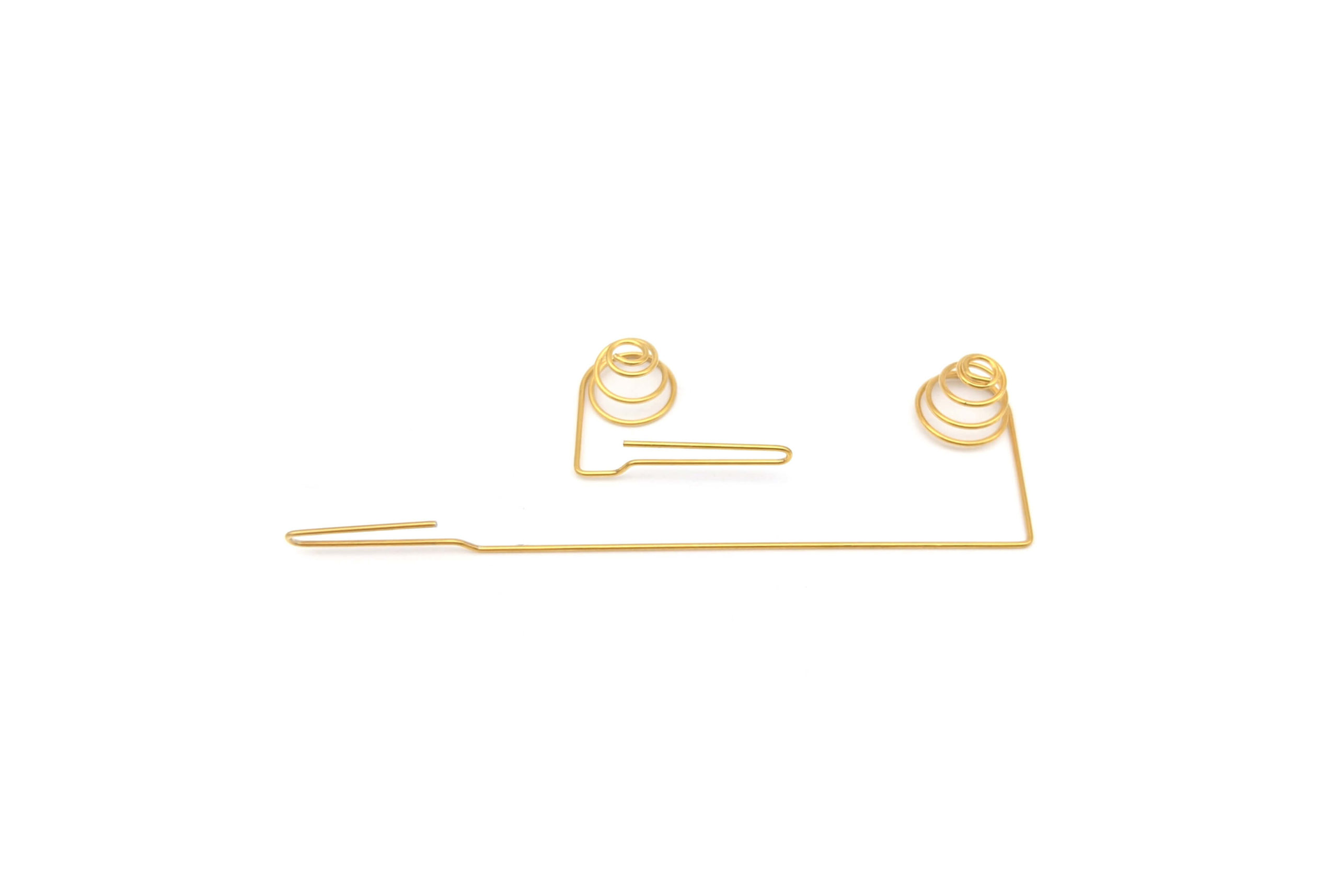

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

In the intricate world of mechanical design, flat springs stand out as essential components, playing a crucial role in countless applications. These unassuming, flat strips of spring steel possess an

In the intricate world of mechanical design, flat springs stand out as essential components, playing a crucial role in countless applications. These unassuming, flat strips of spring steel possess an inherent strength and resilience that make them ideal for a wide range of functions. From the simple act of providing a return force in a door latch to the more complex task of ensuring precise actuation in electrical switches, flat springs are ubiquitous, often working silently behind the scenes to ensure smooth and reliable operation. In this article, we will delve into the fascinating world of flat springs, exploring their characteristics, types, advantages, and the diverse applications that showcase their versatility.

Flat springs, as the name suggests, are essentially thin, flat strips of metal, usually made from spring steel, carefully shaped to achieve their desired function. They're often defined by their resilience – their ability to withstand repeated bending and flexing without permanent deformation. This resilience is crucial for their role in various applications, where they act as reliable force generators and shape retainers.

Within the realm of flat springs, there exists a diversity of types, each tailored to specific applications and loading requirements. Here are some of the commonly encountered flat spring variations:

Cantilever springs are the simplest and perhaps most commonly seen types. They are fixed at one end, with the other end free to deflect under load. Think of a ruler fixed on a table, with a weight placed on the protruding edge – that's a cantilever spring in action. Their single point of support makes them ideal for situations requiring a simple, reliable return force.

Leaf springs, a vital component in the suspension systems of vehicles, especially older models, are flat springs arranged in multiple layers. They act as flexible beams, absorbing the shock and vibration of the road and ensuring a comfortable ride. Each leaf is typically tapered, with the longest leaf at the bottom carrying the most load. This layered design offers a high load capacity and a smooth ride, even over rough terrain.

V-springs, with their distinctive V-shaped design, often find applications in antique firearm mechanisms. They are designed to apply a precise force to the hammer or other moving parts, ensuring reliable ignition. This unique shape provides a controlled and consistent force throughout the spring's travel, crucial for the smooth and accurate operation of these firearms.

Flat springs enjoy a multitude of advantages that have contributed to their widespread use in mechanical engineering and various other fields. These advantages include:

Flat springs are remarkably versatile. Their adaptability allows them to be shaped and customized for a wide range of applications, from the simple to the complex. They can be readily designed to accommodate specific load requirements, deflection patterns, and space constraints, making them suitable for almost any mechanical design challenge.

Flat springs are known for their inherent reliability. Their robust construction, often made from high-quality spring steel, ensures long-lasting performance, even under demanding conditions. This inherent durability makes them a dependable choice for applications where consistent operation is critical.

While the cost of flat springs varies depending on the specific material, shape, and manufacturing process, they are generally considered cost-effective compared to other spring types. Their simple design and efficient manufacturing processes often contribute to lower production costs, making them an attractive option for budget-conscious applications.

Flat springs are capable of delivering accurate and precise forces. Their controlled deformation allows for fine-tuning and precise actuation, making them ideal for applications where precise movement or force control is paramount. This accuracy is crucial for many applications, including electrical switches, medical devices, and precision machinery.

The versatility of flat springs makes them integral components in a vast array of applications across various industries. Here are just a few examples:

Flat springs play a significant role in the automotive industry, primarily in suspension systems. Leaf springs, as discussed earlier, are a cornerstone of traditional suspension systems, while flat springs also find applications in other components like door latches, hood supports, and seat mechanisms.

Flat springs are ubiquitous in electrical appliances, from small household gadgets to larger industrial equipment. They provide the return force in switches, ensuring a smooth and reliable actuation. Their ability to withstand repeated cycles and provide consistent performance makes them ideal for such applications.

Flat springs are essential components in medical devices, where accuracy and reliability are paramount. They are used in surgical instruments, medical imaging equipment, and other devices that require precise movement and controlled forces. Their biocompatibility and resistance to corrosion make them a safe choice for such sensitive applications.

The aerospace industry demands components with exceptional strength, reliability, and resistance to fatigue. Flat springs, particularly those made from high-grade materials, are well-suited for use in aircraft and spacecraft, where they are often employed in control systems, landing gear, and other critical components.

As technology advances, flat springs are continuously evolving, incorporating innovative designs and materials to meet the demands of new and challenging applications. Advancements in materials science and manufacturing processes are leading to lighter, stronger, and more durable flat springs, expanding their capabilities and applications. The future of flat springs promises exciting possibilities in areas like robotics, wearable technology, and advanced manufacturing, where their unique characteristics will continue to be instrumental.

In conclusion, flat springs are unassuming yet indispensable components in the world of mechanical design. Their versatility, reliability, cost-effectiveness, and precision make them a valuable choice across a wide range of applications. As technology continues to evolve, the role of flat springs is likely to expand even further, solidifying their position as workhorses of modern engineering.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.