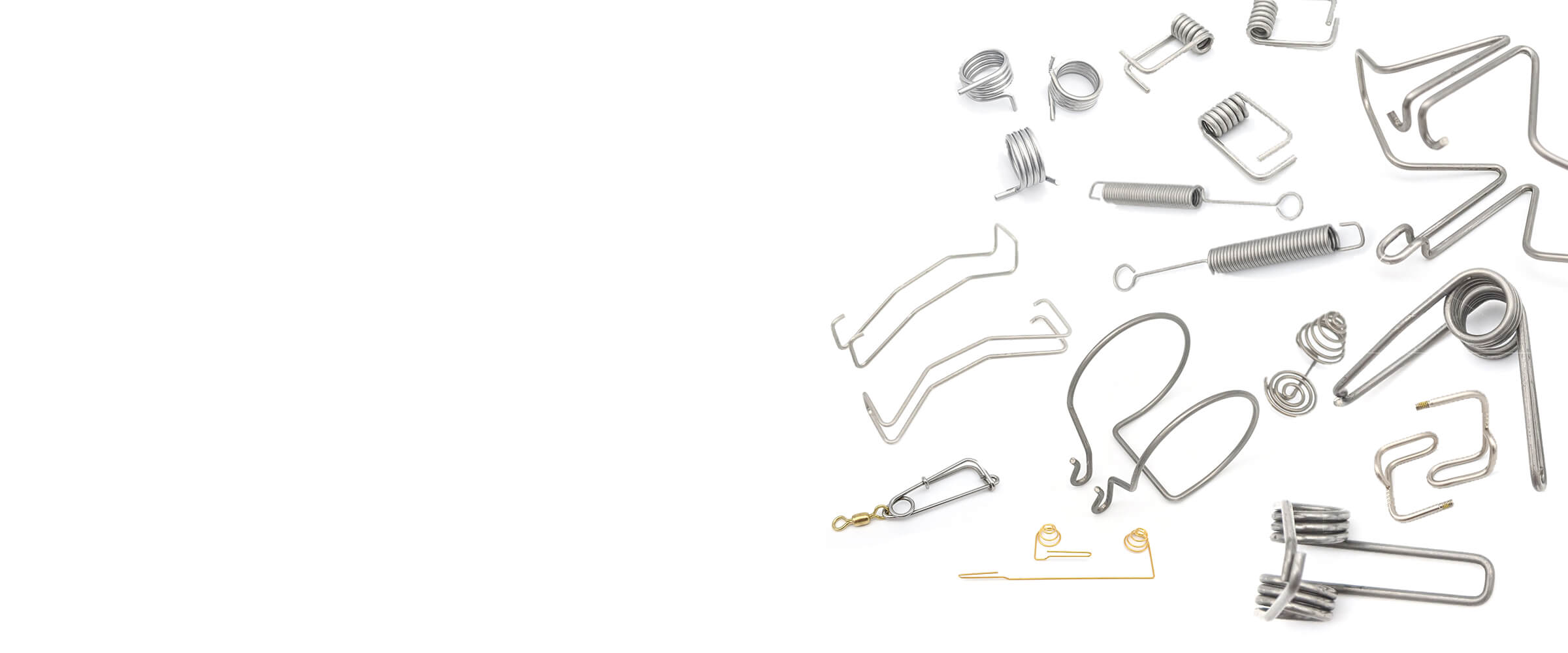

Get unique, complex parts easily. No matter your requirements, Chaoyi Spring creates hard-to-produce coil springs and wire forms.

Let us help you create the custom wire form you need, from S-hooks and J-hooks to utility hooks and more.

We work closely with customers across a wide range of industries, helping them design and manufacture made-to-order parts.

Why choose Chaoyi Spring? We prioritize customer-focused collaboration, modern equipment and the latest technology to make your parts per print.

Find the information and guidance you need, from measuring a spring to learning about materials, placing an order and much more.

Imagine a world without the smooth, silent action of a door hinge, the satisfying click of a switch, or the controlled release of a spring-loaded clamp. These seemingly mundane mechanisms,

Imagine a world without the smooth, silent action of a door hinge, the satisfying click of a switch, or the controlled release of a spring-loaded clamp. These seemingly mundane mechanisms, and countless others, rely on a simple yet ingenious component: the flat spring. These unassuming strips of metal, often overlooked in the grand scheme of engineering marvels, play a pivotal role in countless applications, from the tiniest of electronic devices to the robust machinery that powers our modern world.

Flat springs, as the name suggests, are springs crafted from flat pieces of spring steel. Unlike their coiled counterparts, they derive their elasticity from the inherent bending properties of the material. They are typically designed to flex and return to their original shape, storing and releasing energy as they do so.

The beauty of flat springs lies in their versatility. They can be tailored to a myriad of shapes and sizes, making them adaptable to diverse applications. Their design allows for precise control over the force they exert, the distance they deflect, and the rate at which they return to their original position.

The magic of flat springs lies in their ability to absorb and release energy through bending. When a force is applied to a flat spring, it bends, storing the applied energy as elastic potential energy. Upon release of the force, the spring's inherent elasticity causes it to return to its original shape, releasing the stored energy in the process.

The force required to bend a flat spring, and the distance it will deflect, are determined by several factors, including the material's properties, the spring's dimensions, and its shape. Engineers can fine-tune these parameters to achieve the desired spring characteristics for a specific application.

Flat springs are ubiquitous, quietly working behind the scenes to make our lives easier and more efficient. They are the unsung heroes of countless applications, including:

Flat springs are essential in automotive systems, from the delicate components in a car's ignition system to the robust leaf springs used in truck suspensions. They ensure smooth operation of steering mechanisms, provide tension to belts, and even serve as integral parts of brake systems.

In the realm of electronics, flat springs are used extensively in switches, relays, and connectors. Their precise bending and release properties allow for reliable and consistent electrical contact, ensuring smooth and reliable operation of our electronic devices.

From the simple spring-loaded clips on a bread bag to the complex mechanisms in a washing machine, flat springs are indispensable in household appliances. They provide tension for door latches, control the flow of water in washing machines, and ensure smooth operation of countless other mechanisms.

Even in the delicate world of medical devices, flat springs find their niche. They are used in surgical instruments, catheters, and even prosthetic limbs, providing precise force and control where needed.

In the heavy-duty realm of industrial machinery, flat springs are used in clutches, brakes, and other mechanisms requiring robust and reliable force application. Their ability to withstand high loads and repeated stress makes them ideal for these demanding applications.

Flat springs are a testament to the power of simplicity in engineering. Their unassuming design belies their vast versatility and their crucial role in countless applications. From the smallest of electrical contacts to the most robust of industrial machines, flat springs quietly work behind the scenes, enabling the smooth and efficient operation of our modern world.

The next time you encounter a door hinge, a switch, or any other mechanism that relies on a spring, take a moment to appreciate the understated brilliance of the flat spring, the unassuming hero of countless everyday applications.

Flat springs, though often overlooked, are fundamental components in countless mechanisms, serving as silent yet vital contributors to the smooth and efficient operation of our modern world. Their unassuming nature hides a remarkable versatility, making them an indispensable tool for engineers across diverse industries.

Browse some of the custom wire forms and springs that we manufacture. Don’t see what you need? We specialize in made-to-order products that meet your application requirements.

Visit Our GalleryNeed a custom wire form or coil spring? We make it work. Fill out the contact form and a representative will respond within 1 business day. If you have a PDF or CAD file, you can submit to request a quote.